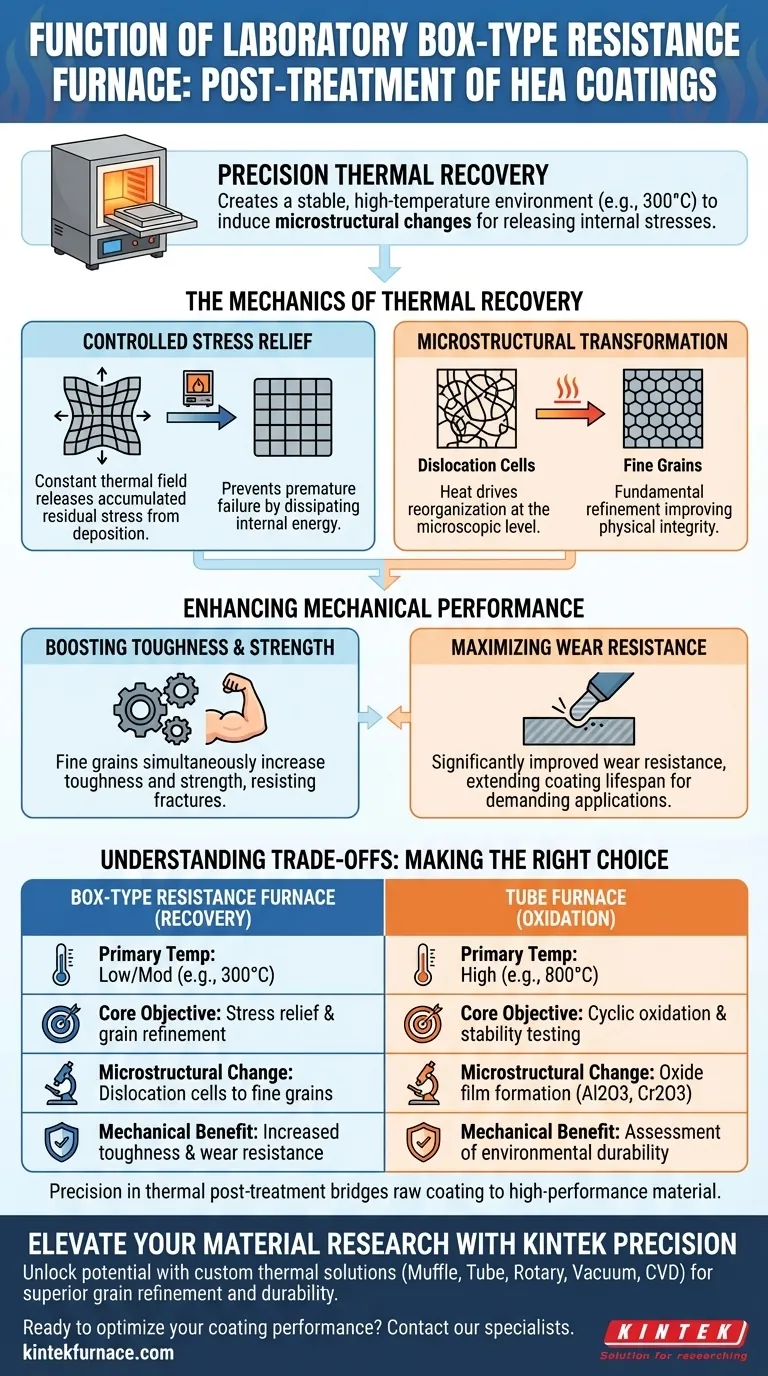

A laboratory box-type resistance furnace serves as a precision instrument for the thermal recovery of high-entropy alloy (HEA) coatings. It creates a stable, high-temperature environment—typically holding samples at constant temperatures such as 300°C—to induce specific microstructural changes. This process is essential for releasing internal stresses and refining the material's grain structure to maximize durability.

The primary role of this furnace is to subject HEA coatings to controlled thermal recovery, transforming internal dislocation structures into fine grains. This process relieves residual stress and boosts both toughness and strength, resulting in superior wear resistance.

The Mechanics of Thermal Recovery

Controlled Stress Relief

High-entropy alloy coatings often accumulate significant residual stress during the deposition process.

The box-type resistance furnace provides a constant thermal field necessary to release these stresses.

By holding the material at a specific temperature (e.g., 300°C) for a set duration, the internal energy is dissipated in a controlled manner, preventing premature failure.

Microstructural Transformation

The heat treatment process drives a critical transformation at the microscopic level.

Under these thermal conditions, dislocation cells within the material reorganize.

These structures transform into fine grains, a refinement that is fundamental to improving the material's physical integrity.

Enhancing Mechanical Performance

Boosting Toughness and Strength

The microstructural changes induced by the furnace are directly responsible for enhanced mechanical properties.

The formation of fine grains leads to a simultaneous increase in both toughness and strength.

This dual improvement ensures the coating can withstand mechanical loads without fracturing.

Maximizing Wear Resistance

The ultimate operational goal of using this furnace is to extend the lifespan of the coating.

A coating that has undergone this recovery treatment exhibits significantly improved wear resistance.

This makes the material far more suitable for demanding industrial applications where surface degradation is a primary concern.

Understanding the Trade-offs

Equipment Specificity

It is crucial to distinguish the box-type furnace from other laboratory heating equipment.

While a box furnace is ideal for recovery treatment and stress relief, it is distinct from a high-temperature tube furnace.

Tube furnaces are typically used for simulating extreme service conditions, such as cyclic oxidation experiments at 800°C to study oxide film formation (e.g., Al2O3 and Cr2O3), rather than microstructural recovery.

Process Precision

The benefits of recovery treatment are highly dependent on precise temperature control.

If the temperature is too low, the transformation of dislocation cells may not occur.

Conversely, excessive temperatures generally reserved for oxidation testing could inadvertently alter the coating's oxidation kinetics rather than optimizing its grain structure.

Making the Right Choice for Your Goal

To maximize the performance of high-entropy alloy coatings, select your thermal process based on the specific property you wish to evaluate or enhance.

- If your primary focus is mechanical durability: Utilize the box-type resistance furnace for recovery treatment (around 300°C) to refine grains and increase wear resistance.

- If your primary focus is environmental stability: Utilize a high-temperature tube furnace (around 800°C) to simulate service conditions and assess antioxidant potential.

Precision in thermal post-treatment is the bridge between a raw coating and a high-performance engineering material.

Summary Table:

| Process Feature | Box-Type Resistance Furnace (Recovery) | Tube Furnace (Oxidation) |

|---|---|---|

| Primary Temperature | Low to Moderate (e.g., 300°C) | High (e.g., 800°C) |

| Core Objective | Stress relief & grain refinement | Cyclic oxidation & stability testing |

| Microstructural Change | Dislocation cells to fine grains | Oxide film formation (Al2O3, Cr2O3) |

| Mechanical Benefit | Increased toughness & wear resistance | Assessment of environmental durability |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your high-entropy alloy coatings with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific laboratory requirements. Whether you need precise thermal recovery in a box furnace or extreme environment simulation in a tube furnace, our equipment delivers the accuracy and uniformity essential for superior grain refinement and mechanical durability.

Ready to optimize your coating performance? Contact our laboratory specialists today to find the perfect furnace for your unique research needs.

Visual Guide

References

- Chong Zhang, Hongyuan Liu. Effect of Recovery Treatment on the Microstructure and Tribological Properties of Ultrasonic Impacted Al2FeCoNiCrW0.5 High-Entropy Alloy Coatings. DOI: 10.3390/coatings15010083

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a batch type furnace? Master Precision Heat Treatment for Diverse Materials

- What are the standard specifications for Box Furnaces? Key Components for Precision and Efficiency

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- Why is a high-temperature muffle furnace required for the incineration treatment of titanium dioxide nanoparticles?

- What specialized processes can a box furnace facilitate? Unlock Precision Material Transformation

- What are some common applications of a box type resistance furnace? Versatile High-Temp Solutions for Labs and Industry

- What are common high-temperature applications of muffle furnaces in laboratories? Unlock Precision in Material Testing and Synthesis

- What is the function of a high-temperature box resistance furnace? Optimize Hierarchical Zeolite Synthesis