At its core, an induction furnace is used to melt metal. From less than a kilogram of precious metal in a lab to one hundred tons of steel in a foundry, its primary function is to transform solid metal into a liquid state using clean, non-contact electromagnetic heating. This technology is applied across industries for melting iron, steel, copper, aluminum, and precious metals for casting, alloy manufacturing, and other high-purity processes.

An induction furnace's value isn't just that it melts metal, but how it melts it. The technology's true advantage lies in its unique combination of efficiency, purity, and control, which traditional fuel-fired methods cannot match.

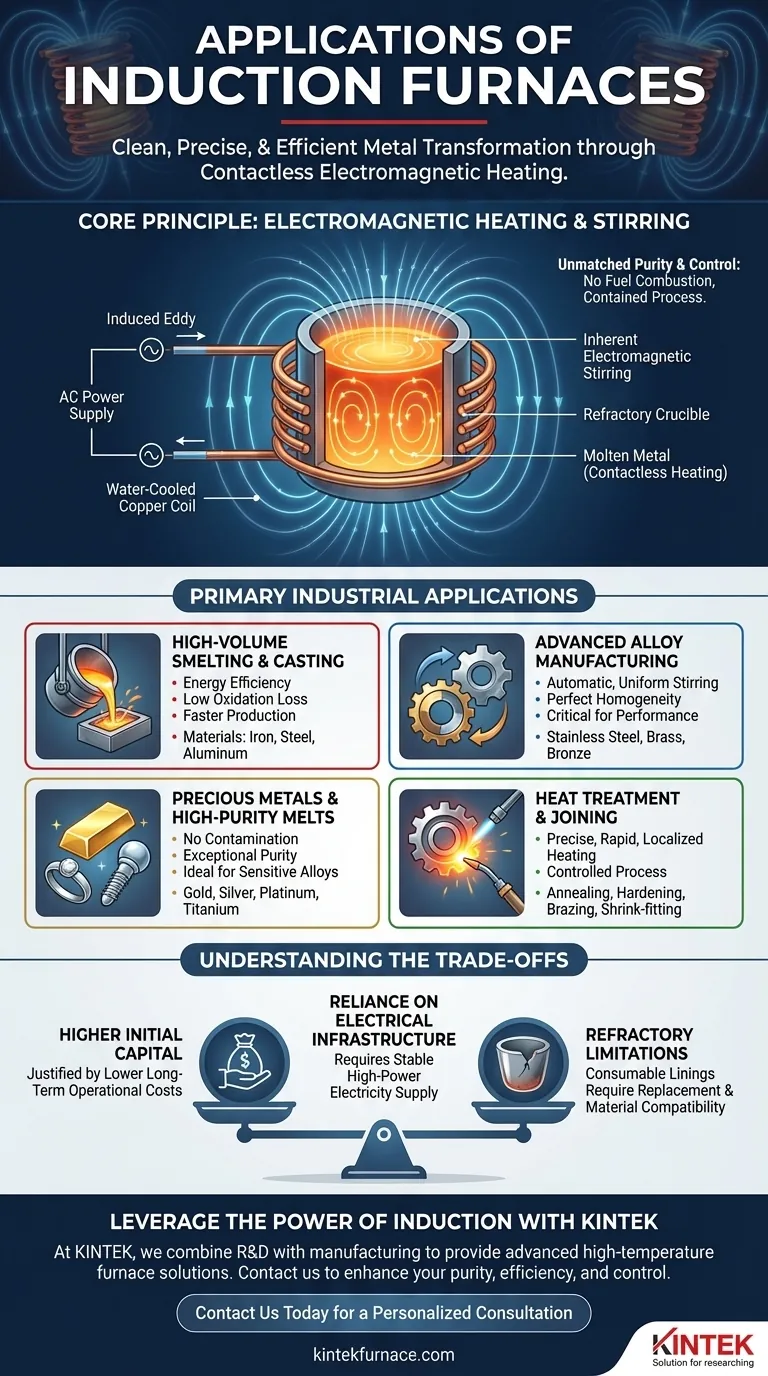

The Principle Driving the Application: Clean, Contained Energy

To understand why induction furnaces are chosen for specific tasks, you must first understand the fundamental principle that sets them apart.

Contactless Electromagnetic Heating

An induction furnace does not burn fuel. Instead, a powerful alternating current flows through a water-cooled copper coil, creating a strong magnetic field. When conductive material like metal is placed inside this field, it induces an electrical current (an "eddy current") within the metal itself, generating intense heat and causing it to melt without any direct contact from a heat source.

Inherent Electromagnetic Stirring

The same magnetic field that heats the metal also creates a stirring action within the molten bath. This natural, continuous mixing is a critical advantage, ensuring that alloys are blended with exceptional uniformity without the need for mechanical stirrers that could introduce impurities.

Unmatched Purity and Control

Because there is no combustion, no fuel byproducts like carbon or sulfur can contaminate the melt. The process is entirely contained within a neutral refractory crucible, making it ideal for creating high-purity metals and sensitive alloys. Temperature is also controlled with high precision by simply adjusting the power to the coil.

Primary Industrial Applications

The unique characteristics of induction heating lead to its adoption in several key industrial areas.

High-Volume Smelting and Casting

This is the most common application. Foundries use large induction furnaces to melt iron, steel, and aluminum for casting parts. The process is fast, energy-efficient, and produces less oxidation loss compared to cupola or arc furnaces, leading to higher quality final products like engine blocks, pipes, and machine components.

Advanced Alloy Manufacturing

The automatic stirring action makes induction furnaces the standard for creating specialty alloys. Whether blending steel with chromium and nickel for stainless steel or creating unique brass or bronze formulations, the electromagnetic mixing ensures a perfectly homogenous final material, which is critical for performance.

Precious Metals and High-Purity Melts

For applications where purity is paramount, induction is the only logical choice. It is used to melt gold, silver, and platinum group metals for investment casting and jewelry. It is also essential for producing medical-grade titanium or superalloys for the aerospace industry, where even trace impurities can cause catastrophic failure.

Heat Treatment and Joining

The precise and rapid heating of induction isn't just for melting. It is also widely used for heat-treating metal parts. Applications include:

- Annealing: Softening a metal to increase its ductility.

- Hardening & Tempering: Modifying the surface of steel parts like gears or shafts for wear resistance.

- Brazing: Joining two pieces of metal together with a filler metal.

- Shrink-fitting: Heating a part to expand it so it can be fitted over another part.

Understanding the Trade-offs

While powerful, induction technology is not a universal solution. It comes with specific considerations.

Initial Capital Investment

Induction furnace systems, with their power supplies and water-cooling infrastructure, typically have a higher upfront cost than simple fuel-fired furnaces. This investment is justified by lower long-term operational costs and higher material quality.

Reliance on Electrical Infrastructure

The process is highly efficient, but it requires a stable and robust supply of high-power electricity. Its environmental benefit is also directly tied to how cleanly that electricity is generated.

Refractory Limitations

The crucible containing the molten metal (the refractory lining) is a consumable item that wears out over time and must be replaced. The choice of refractory material is critical and must be compatible with the specific metal being melted to avoid chemical reactions and contamination.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your end goal.

- If your primary focus is high-purity or specialty alloys: Induction is the superior choice due to its clean, contactless heating and inherent electromagnetic stirring.

- If your primary focus is high-volume, general-purpose melting: Evaluate induction's energy efficiency and lower operational costs against the initial capital investment compared to traditional furnaces.

- If your primary focus is precise heat treatment or joining: Induction offers unmatched speed and localized control for applications like surface hardening, annealing, or brazing.

By understanding the core principles of induction technology, you can leverage its distinct advantages for your specific manufacturing needs.

Summary Table:

| Application Area | Key Benefit | Common Materials |

|---|---|---|

| High-Volume Smelting & Casting | Energy efficiency, low oxidation loss | Iron, Steel, Aluminum |

| Advanced Alloy Manufacturing | Automatic, uniform stirring | Stainless Steel, Brass, Bronze |

| Precious Metals & High-Purity Melts | No contamination, exceptional purity | Gold, Silver, Platinum, Titanium |

| Heat Treatment & Joining | Precise, localized, rapid heating | Steel parts for annealing, hardening, brazing |

Ready to leverage the power of induction for your metal melting or heat treatment needs?

At KINTEK, we combine exceptional R&D with in-house manufacturing to provide advanced high-temperature furnace solutions. Whether your application requires a standard induction furnace or a deeply customized system for unique experimental requirements, our expertise in Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD furnaces ensures you get the precise performance you need.

Contact us today to discuss how our solutions can enhance your purity, efficiency, and control. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency