At its core, a laboratory tube furnace is a high-precision heating device designed to create an exceptionally uniform and stable temperature environment. It consists of a cylindrical chamber with heating elements surrounding a central work tube, which contains the sample being processed for applications ranging from materials synthesis to thermal analysis.

The design of a tube furnace is not arbitrary; every element, from its cylindrical shape to its material composition, is optimized to achieve one primary goal: delivering precise and highly uniform heat to a sample in a controlled atmosphere.

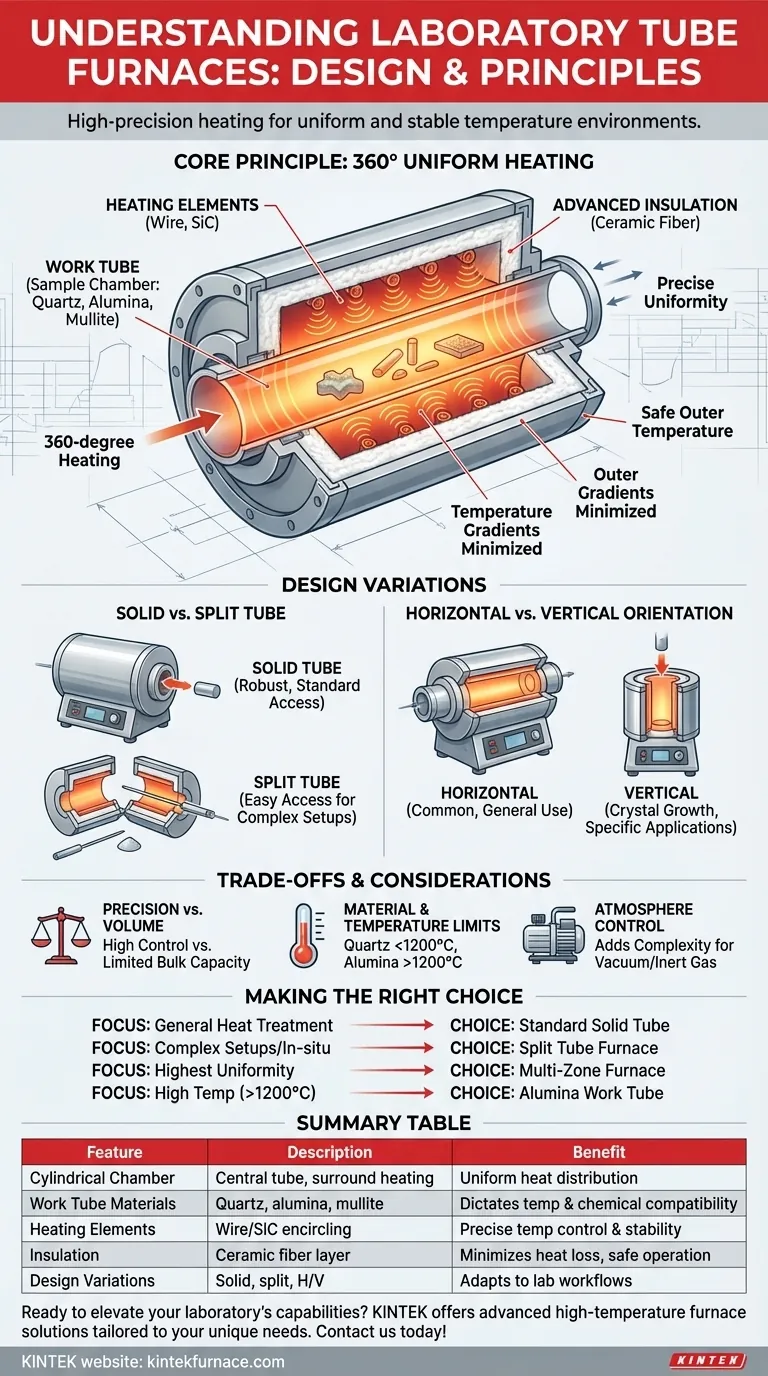

The Core Principle: Uniformity Through Design

The effectiveness of a tube furnace comes from its simple, purpose-built geometry. Unlike a box furnace or hot plate where heat is often directional, a tube furnace envelops the sample in a consistent thermal environment.

The Central Work Tube

The sample is never in direct contact with the heating elements. Instead, it is placed inside a separate, often removable work tube made of materials like quartz, alumina, or mullite. This tube acts as the process chamber.

The choice of tube material is critical as it dictates the maximum operating temperature and chemical compatibility of the furnace.

Circumferential Heating Elements

The heating elements, typically made of high-resistance wire or silicon carbide, are positioned to fully encircle the work tube.

This 360-degree heating is the key to the furnace's exceptional thermal uniformity. Heat radiates inward from all directions, minimizing the temperature gradients that can ruin sensitive experiments.

Advanced Insulation

Surrounding the heating elements is a thick layer of high-performance ceramic fiber insulation. This has two functions: it minimizes heat loss to ensure temperature stability and energy efficiency, and it keeps the outer casing of the furnace cool to the touch for safe operation.

Key Design Variations and Their Purpose

While all tube furnaces share the same core principle, their physical design is adapted for different laboratory workflows and applications.

Solid Tube Furnaces

This is the most common and straightforward design. The furnace is a single, solid cylinder that the work tube slides into. It is robust, simple, and ideal for most standard heat treatment processes where the sample can be easily loaded and unloaded from one end.

Split Tube Furnaces

As the name implies, a split tube furnace is built in two halves connected by a hinge. This allows the chamber to be opened completely, providing direct access to the work tube.

This design is essential when working with samples that have fixed connections, such as probes for in-situ measurements, or when using complex sealed-tube apparatus that cannot be slid into place.

Vertical vs. Horizontal Orientation

Tube furnaces can be used in either a horizontal or vertical orientation. Horizontal is most common, but vertical operation is critical for specific applications like crystal growth (Bridgman method) or when samples need to be dropped into the hot zone to initiate a reaction.

Understanding the Trade-offs

While powerful, the tube furnace design involves specific limitations that you must consider for any application.

Precision vs. Sample Volume

The defining feature of a tube furnace—its tubular chamber—inherently limits the physical size and volume of the sample. This is the fundamental trade-off: you gain exceptional temperature control at the cost of bulk processing capacity.

Material and Temperature Limits

The furnace's maximum temperature is limited by both the heating elements and the work tube material. For example, a quartz tube is excellent for its purity and visibility but typically cannot exceed ~1200°C. Higher temperatures require robust ceramic tubes like alumina.

Atmosphere Control Adds Complexity

Many processes require a specific atmosphere (e.g., vacuum, inert gas like argon, or a reactive gas). While tube furnaces are ideal for this, it requires adding vacuum flanges, seals, and gas flow systems, which increases the complexity and potential for leaks.

Making the Right Choice for Your Application

Selecting the correct furnace design is critical for achieving reliable and repeatable results.

- If your primary focus is general heat treatment or synthesis: A standard, single-zone solid tube furnace is the most cost-effective and reliable choice.

- If your primary focus is working with complex setups or in-situ measurements: A split tube furnace is essential for its easy access to the sample chamber.

- If your primary focus is achieving the highest possible temperature uniformity: Look for a multi-zone furnace, which uses multiple independent heating zones to flatten the temperature profile along the tube's length.

- If your primary focus is high-temperature processing (>1200°C): You must select a furnace with appropriate high-temperature elements and an alumina ceramic work tube.

Understanding these design principles allows you to move beyond simply operating the equipment to truly mastering your thermal processing goals.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Cylindrical Chamber | Central work tube surrounded by heating elements | Ensures uniform 360-degree heat distribution |

| Work Tube Materials | Quartz, alumina, or mullite | Dictates temperature limits and chemical compatibility |

| Heating Elements | High-resistance wire or silicon carbide encircling tube | Provides precise temperature control and stability |

| Insulation | Ceramic fiber layer | Minimizes heat loss and ensures safe operation |

| Design Variations | Solid, split, horizontal/vertical orientation | Adapts to different lab workflows and sample setups |

| Applications | Materials synthesis, thermal analysis, crystal growth | Supports diverse high-temperature processes in controlled atmospheres |

Ready to elevate your laboratory's capabilities with a custom tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in materials science, chemistry, or research, we can help you achieve precise thermal processing with reliable, efficient equipment. Contact us today to discuss how we can support your experimental goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab