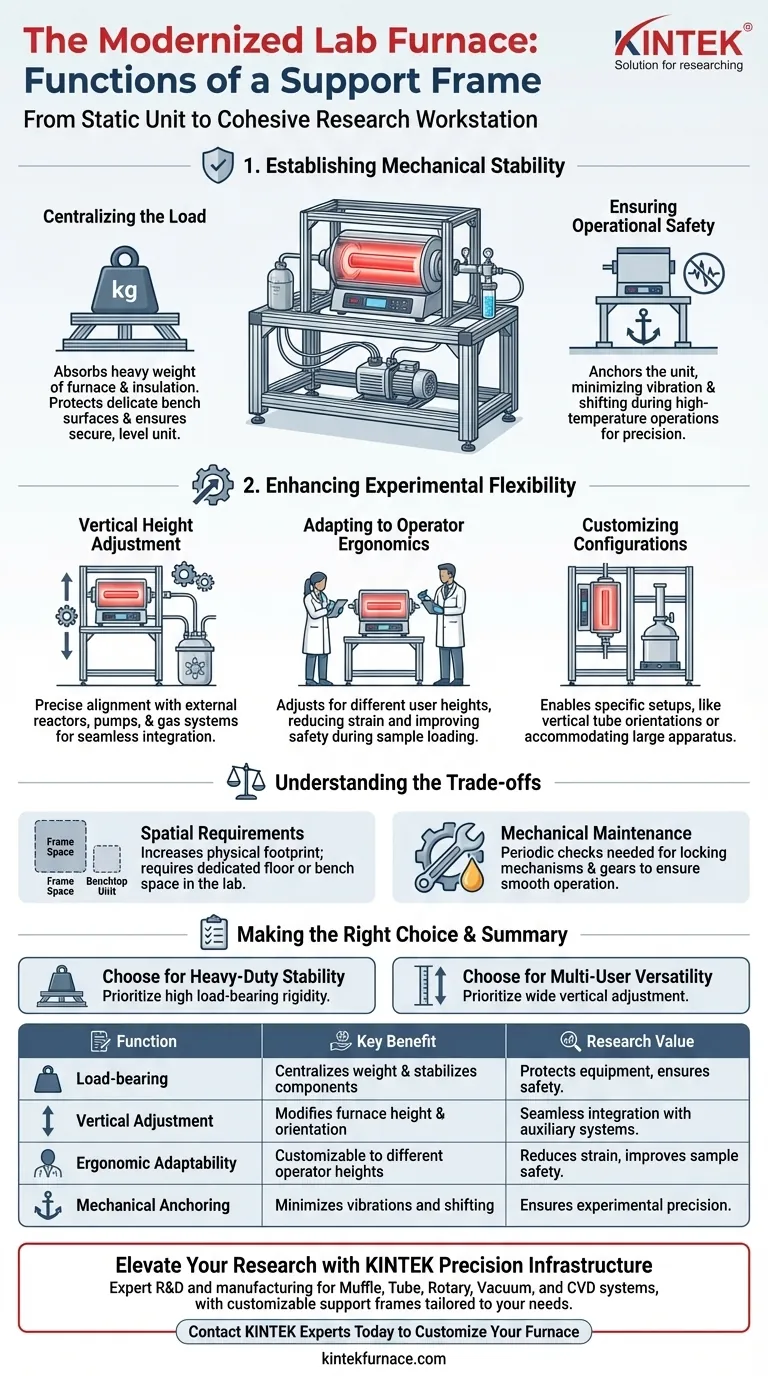

The support frame acts as the foundational backbone for a modernized laboratory tube furnace. Its primary function is to transform the furnace into a cohesive research workstation by providing a stable, load-bearing structure that safely supports the equipment's weight while enabling critical vertical height adjustments for experimental versatility.

Modernizing a lab furnace requires more than just updated heating elements; it demands a robust physical infrastructure. A dedicated support frame serves as the core structure that bridges the gap between heavy mechanical stability and the flexible needs of a dynamic research environment.

Establishing Mechanical Stability

Centralizing the Load

The most fundamental function of the support frame is load-bearing capacity. Laboratory tube furnaces are often heavy, utilizing dense insulation and ceramic components.

The frame absorbs this weight, removing stress from delicate bench surfaces or temporary stands. This ensures the unit remains secure and level at all times.

Ensuring Operational Safety

Beyond simple weight support, the frame guarantees overall mechanical stability.

During high-temperature operations, minimizing vibration or shifting is critical. A dedicated frame anchors the furnace, preventing accidental movement that could disrupt sensitive experiments or compromise safety.

Enhancing Experimental Flexibility

Vertical Height Adjustment

A key feature of a modernized frame is the ability to adjust the furnace's vertical position.

This is not merely a convenience; it allows the furnace to interact with different auxiliary equipment. By changing the height, researchers can align the heating zone precisely with external reactors, vacuum pumps, or gas delivery systems.

Adapting to Operator Ergonomics

Modernization implies improved usability. The height adjustment feature allows the workstation to adapt to different operator heights.

This ergonomic flexibility reduces strain on the researcher, allowing for safer and more comfortable loading and unloading of samples.

Customizing for Specific Configurations

Research requirements change rapidly. A static furnace is limited, but a frame-mounted furnace is adaptable.

The adjustability allows for specific experimental configurations, such as creating clearance for vertical tube orientations or accommodating large apparatus beneath the heating zone.

Understanding the Trade-offs

Spatial Requirements

While a support frame adds functionality, it inevitably increases the physical footprint of the setup.

Unlike a compact benchtop unit, a frame-based workstation requires dedicated floor or bench space. You must ensure your laboratory layout can accommodate the dimensions of the structure.

Mechanical Maintenance

Adding adjustability introduces moving parts to the infrastructure.

While a static bench requires no care, a height-adjustable frame may require periodic checks to ensure the locking mechanisms and adjustment gears remain smooth and secure over time.

Making the Right Choice for Your Goal

To maximize the value of your laboratory modernization, consider your specific research priorities:

- If your primary focus is heavy-duty stability: Prioritize a frame with a reinforced base and high load-bearing specifications to ensure absolute rigidity during operation.

- If your primary focus is multi-user versatility: Prioritize a frame with a wide range of vertical adjustment to easily accommodate different operator heights and varied experimental setups.

A well-integrated support frame is not just a stand; it is a critical tool that stabilizes your current work while adapting to your future research needs.

Summary Table:

| Function | Key Benefit | Research Value |

|---|---|---|

| Load-bearing | Centralizes weight & stabilizes components | Protects equipment and ensures safety during high-temp runs |

| Vertical Adjustment | Modifies furnace height & orientation | Allows seamless integration with vacuum pumps and external reactors |

| Ergonomic Adaptability | Customizable to different operator heights | Reduces physical strain and improves sample loading safety |

| Mechanical Anchoring | Minimizes vibrations and shifting | Ensures experimental precision for sensitive material processing |

Elevate Your Research with KINTEK Precision Infrastructure

Don't let a static setup limit your laboratory's potential. KINTEK provides more than just high-performance equipment; we offer the foundation for advanced research. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable support frames tailored to your unique experimental needs.

Whether you require heavy-duty load-bearing stability or flexible vertical positioning for complex gas delivery systems, our team is ready to design your ideal high-temperature workstation.

Contact KINTEK Experts Today to Customize Your Furnace

Visual Guide

References

- Beata Brzychczyk, L. J. Sikora. Modernization of a Tube Furnace as Part of Zero-Waste Practice. DOI: 10.3390/su17198940

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does the use of a tube furnace for nitrogen-protected annealing affect tin oxide catalysts? Unlock Superior Activity

- What role does a high-temperature tube furnace play in the preparation of cellulose-based carbon nanofibers?

- What are the main applications of a drop tube furnace? Unlock Insights in Energy and Materials Research

- What role does a laboratory tube furnace play in STO thin film annealing? Unlock Neuromorphic Potential

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What is the recommended procedure for maintaining atmosphere purity in a vacuum tube experimental furnace? Ensure High-Purity Results

- What role does a laboratory tube furnace play in geological and mineralogical research? Unlock Earth's Secrets with Precision

- How is a tube high-temperature furnace utilized in the preparation of NiSA-O/Mo2C catalysts? Expert Synthesis Guide