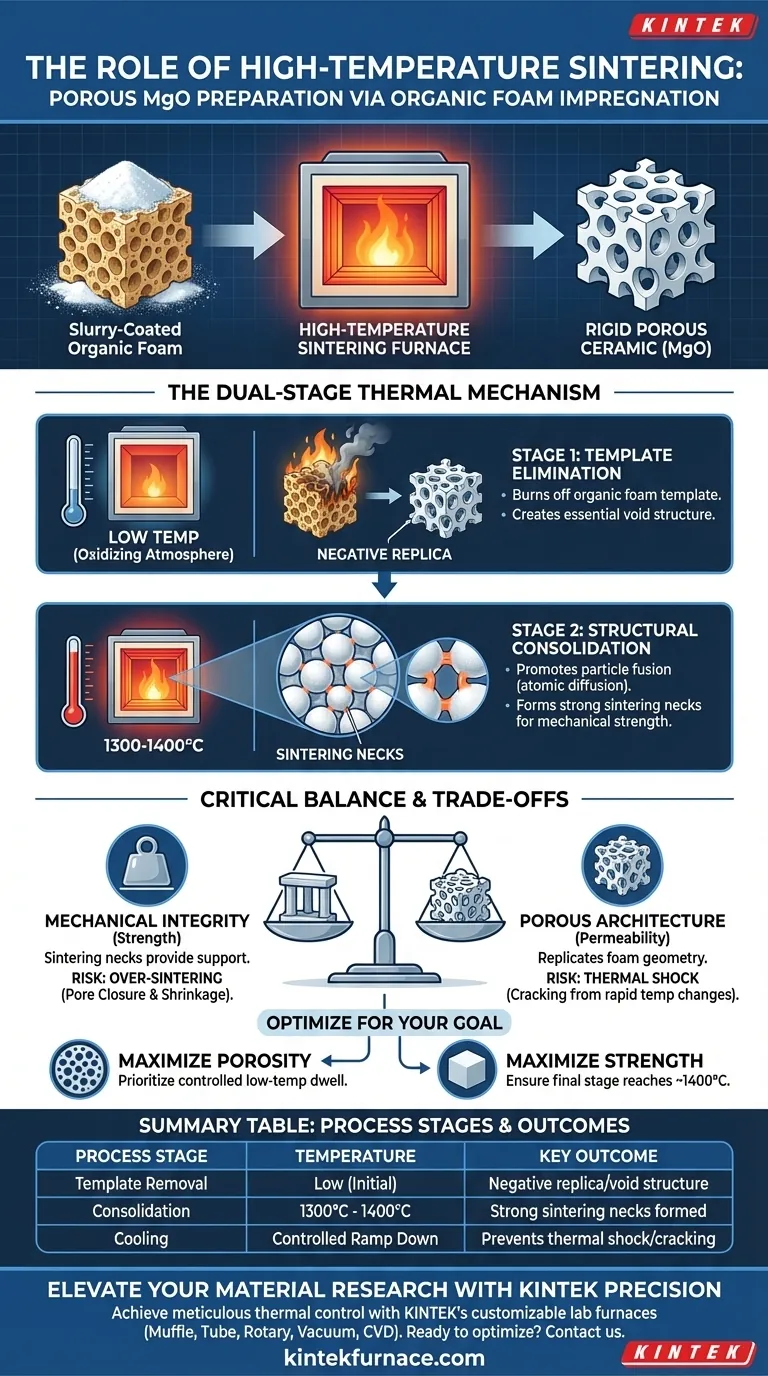

In the preparation of porous magnesium oxide via the organic foam impregnation method, the high-temperature sintering furnace performs two distinct but critical functions: template removal and structural consolidation. It operates first at lower temperatures to oxidize and eliminate the organic foam template, and subsequently at high temperatures (typically 1300-1400°C) to fuse the ceramic particles together.

The sintering furnace acts as the transformational vessel that converts a fragile, slurry-coated foam into a rigid ceramic. It must carefully balance the complete destruction of the organic scaffold with the formation of strong "sintering necks" between magnesium oxide particles to prevent structural collapse.

The Dual-Stage Thermal Mechanism

Stage 1: Template Elimination

The initial function of the furnace is to act as an incinerator for the sacrificial structure. At lower temperatures, the furnace creates an oxidizing atmosphere.

This environment allows the organic foam template (commonly polyurethane) to burn off completely. This step leaves behind a negative replica of the foam, creating the essential void structure of the final porous material.

Stage 2: Structural Consolidation

Once the template is removed, the furnace shifts its function to densification. The temperature is raised significantly, often reaching 1300-1400°C.

At this stage, the furnace promotes the growth of sintering necks between individual magnesium oxide particles. This atomic diffusion bridges the gaps between particles, converting loose powder into a solid, interconnected framework.

Why This Process Determines Quality

Establishing Mechanical Integrity

Without the high-temperature phase, the material would remain a fragile shell of dried powder. The formation of sintering necks provides the necessary mechanical strength.

This bonding ensures the porous ceramic framework can support its own weight and withstand external physical stresses without crumbling.

Preserving the Porous Architecture

The furnace must precisely replicate the geometry of the original foam. By controlling the burn-off rate, the furnace ensures the ceramic coating does not collapse as the inner organic support disappears.

This results in a final product that maintains the high permeability and surface area required for porous applications.

Critical Trade-offs in Sintering

The Risk of Over-Sintering

While high temperatures are needed for strength, excessive heat or prolonged time in the furnace can be detrimental.

If the sintering process is too aggressive, the material may shrink excessively. This can lead to pore closure, effectively destroying the "porous" characteristic you are trying to create.

The Danger of Thermal Shock

The transition between the burn-off phase and the high-temperature sintering phase requires careful control.

Ramping temperatures too quickly can cause cracks in the ceramic skeleton. The organic gases must escape slowly enough to avoid rupturing the fragile magnesium oxide walls before they have fully hardened.

Making the Right Choice for Your Goal

To optimize your magnesium oxide preparation, tailor your furnace schedule to your specific performance requirements:

- If your primary focus is maximizing porosity: Prioritize a controlled lower-temperature dwell time to ensure complete template removal without inducing premature shrinkage or pore closure.

- If your primary focus is mechanical strength: Ensure the final sintering stage reaches the upper range (near 1400°C) to maximize the thickness and durability of the sintering necks between particles.

Success in this method relies not just on reaching the target temperature, but on controlling the transition from template removal to particle fusion.

Summary Table:

| Process Stage | Function | Temperature Range | Key Outcome |

|---|---|---|---|

| Template Removal | Oxidizes/burns off organic foam (PU) | Low (Initial) | Creates negative replica/void structure |

| Consolidation | Promotes atomic diffusion & particle fusion | 1300℃ - 1400℃ | Formation of strong sintering necks |

| Cooling | Hardens the ceramic framework | Controlled Ramp Down | Prevents thermal shock and cracking |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect balance between porosity and mechanical strength requires meticulous thermal control. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of ceramic sintering.

Whether you need precise atmospheric control for template removal or high-temperature stability for densification, our customizable lab furnaces are built to your unique specifications.

Ready to optimize your sintering process? Contact our technical experts today to find the ideal high-temperature solution for your laboratory.

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- How does modern vacuum heat treatment furnaces ensure accurate processing? Achieve Perfect Results with Precision Control

- Why is the selection of insulation layer materials critical for vacuum sintering furnace design? Boost Thermal Efficiency

- What is the role of a high-temperature sintering furnace? Achieve Full Densification for Metal Components

- How is the heating chamber of a vacuum annealing furnace constructed? Optimize Your Material Processing

- What are the steps involved in a typical vacuum brazing treatment? Master the Process for Strong, Clean Joints

- How does a vacuum annealing furnace contribute to microstructural recovery of ODS steel? Unlock Material Performance

- What is the primary function of a vacuum annealing furnace? Optimize Zircaloy-4 Alloy Pretreatment and Purity

- How do miniature vacuum furnaces ensure image stability? Advanced Engineering for High-Resolution Ceramic Imaging