At its core, modern vacuum heat treatment ensures accurate processing through a synergistic combination of precise digital control systems, advanced atmospheric management via high-performance pumps, and superior thermal insulation. This integrated approach allows for the exact regulation of temperature, heating and cooling rates, and pressure, eliminating environmental variables that cause defects.

The defining characteristic of a modern vacuum furnace is its ability to create a highly controlled and repeatable environment. By removing atmospheric contaminants and giving operators precise command over every phase of the thermal cycle, these systems transform heat treatment from an approximation into an exact science.

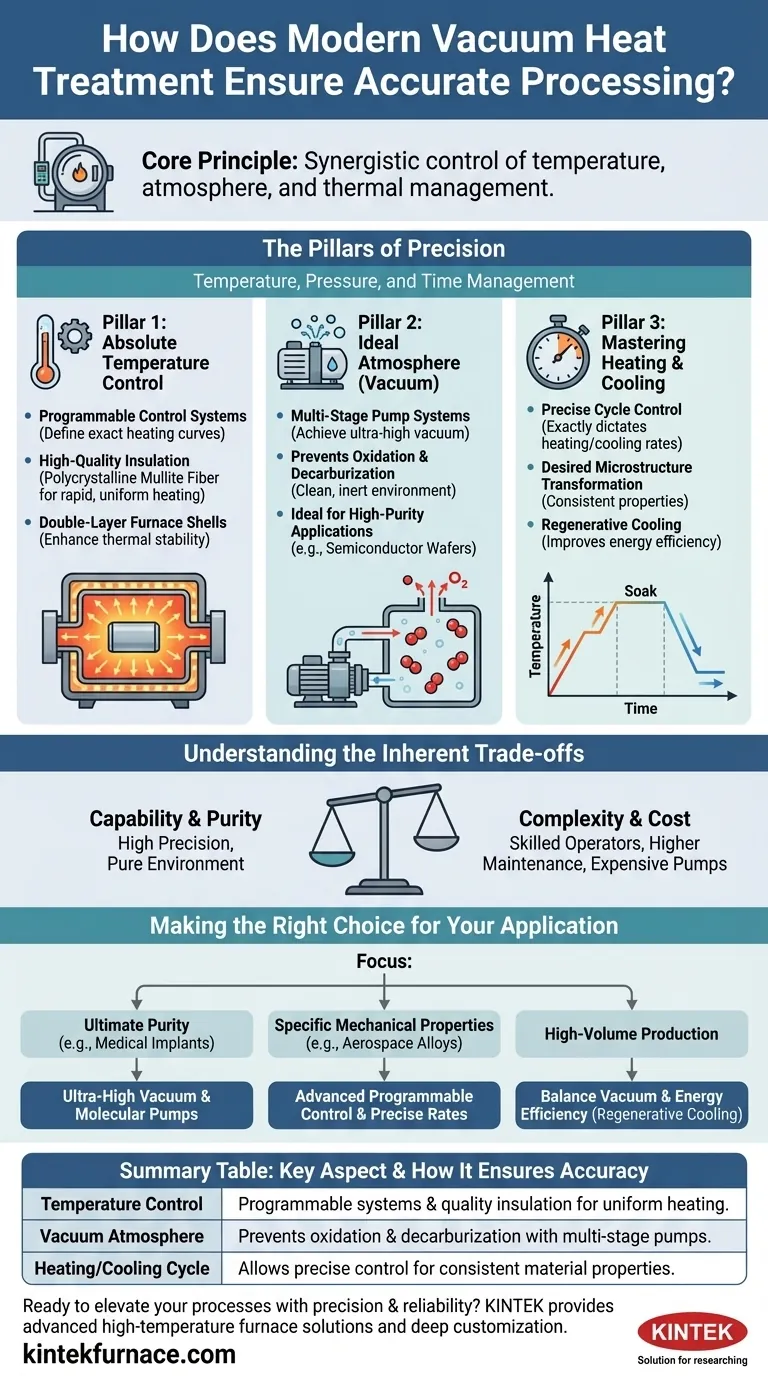

The Pillars of Precision: Temperature, Pressure, and Time

The accuracy of any heat treatment process depends on the flawless management of three fundamental variables. Modern vacuum furnaces are engineered to provide unparalleled control over each one.

Pillar 1: Absolute Temperature Control

Precise temperature is the foundation of successful heat treatment. Furnaces achieve this through a multi-faceted approach.

High-quality insulation, often made of polycrystalline mullite fiber, allows for rapid heating cycles while minimizing heat loss. This ensures the energy input is directed efficiently to the material load.

Programmable control systems are the brain of the operation. They allow operators to define and execute complex heating programs, setting specific temperatures, soak times, and ramp rates to create a perfect, repeatable heating curve.

Features like double-layer furnace shells and advanced air insulation further enhance thermal stability, ensuring the temperature inside the chamber is uniform and consistent with the programmed setpoints.

Pillar 2: Creating the Ideal Atmosphere (Vacuum)

The "vacuum" in a vacuum furnace is its most critical feature for preventing unwanted chemical reactions.

By removing oxygen and other reactive gases, these furnaces completely prevent oxidation and decarburization on the material's surface. This is essential for maintaining the integrity and intended properties of sensitive metals and alloys.

Ultra-high vacuum levels (as low as 7×10⁻⁴ Pa) are achieved using multi-stage pump systems. A mechanical pump creates the initial rough vacuum, and a diffusion or molecular pump then takes over to remove the remaining molecules.

This clean, inert environment is indispensable for high-purity applications, such as the annealing of semiconductor wafers or the synthesis of sensitive magnetic materials, where any contamination would be catastrophic.

Pillar 3: Mastering the Heating and Cooling Cycle

The final properties of a material are determined not just by the peak temperature, but by the speed at which it gets there and, critically, how it cools down.

Modern furnaces provide precise control over the entire cycle. The same programmable systems that manage heating also dictate the cooling process, ensuring specific rates required for processes like annealing, tempering, or precipitation hardening.

This level of control ensures that the material's internal microstructure is transformed exactly as intended, producing the desired hardness, ductility, or stress relief. Repeatability is a key outcome; the first part processed will have the same properties as the last.

Advanced systems may also incorporate regenerative cooling, which not only helps control the cooling rate but also improves energy efficiency by recycling heat.

Understanding the Inherent Trade-offs

While incredibly powerful, the precision of vacuum furnace technology comes with considerations that every user must weigh.

Complexity vs. Capability

The advanced programmable controls and multi-stage vacuum systems that enable such high precision also introduce operational complexity. Achieving optimal results requires skilled operators who can develop and fine-tune process recipes.

Cost of Purity

Higher vacuum levels provide a purer processing environment but come at a significant cost. The pumps required for ultra-high vacuum are more expensive to purchase, operate, and maintain than basic mechanical pumps. The level of vacuum must be matched to the actual needs of the material.

Maintenance and Uptime

A vacuum furnace is a complex system of seals, pumps, and sensors. Maintaining the integrity of the vacuum chamber is critical. Regular maintenance schedules are non-negotiable to prevent leaks and ensure the system performs to specification, which represents an ongoing operational commitment.

Making the Right Choice for Your Application

The right furnace configuration depends entirely on your end goal. Use this as a guide to focus your requirements.

- If your primary focus is ultimate purity and preventing contamination (e.g., semiconductors, medical implants): Prioritize a system with multi-stage diffusion or molecular pumps capable of achieving ultra-high vacuum levels.

- If your primary focus is achieving specific mechanical properties (e.g., aerospace alloys, tool steel): Emphasize a furnace with a highly advanced programmable control system that offers granular command over heating and cooling rates.

- If your primary focus is high-volume, repeatable production: Look for a system that balances good vacuum performance with energy efficiency features like superior insulation, VFDs, and regenerative cooling to manage operational costs.

By understanding how these systems integrate control, atmosphere, and thermal management, you can confidently select and operate the technology to achieve perfectly accurate results.

Summary Table:

| Key Aspect | How It Ensures Accuracy |

|---|---|

| Temperature Control | Uses programmable systems and high-quality insulation for uniform heating and exact temperature regulation. |

| Vacuum Atmosphere | Prevents oxidation and decarburization with multi-stage pumps, ensuring a clean, inert environment. |

| Heating/Cooling Cycle | Allows precise control over rates for consistent material properties and repeatability. |

Ready to elevate your heat treatment processes with precision and reliability? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, semiconductors, or high-volume production, we can help you achieve accurate, repeatable results. Contact us today to discuss how our tailored solutions can benefit your specific application!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How is a vacuum annealing furnace utilized in the materials science and metallurgy industry? Enhance Material Purity and Performance

- Why is a vacuum device essential for removing air bubbles within simulated scrap steel? Enhance Your Fluid Experiments

- What conditions does a vacuum furnace provide for Nb3Sn repair? Precision Heat and High Vacuum for Superconductors

- What is the role of inert gases in vacuum furnace operations? Protecting Metal Purity After Purification

- Why is a vacuum environment important for high-temperature metal processing? Prevent Oxidation and Boost Metal Purity

- What is the necessity of using a vacuum drying oven before LPBF? Ensure Purity & Density in Metal 3D Printing

- How is chamber customization beneficial in vacuum furnaces? Boost Purity, Efficiency, and Performance

- What are the main functions of an annealing furnace? Achieve Precise Material Control and Enhanced Performance