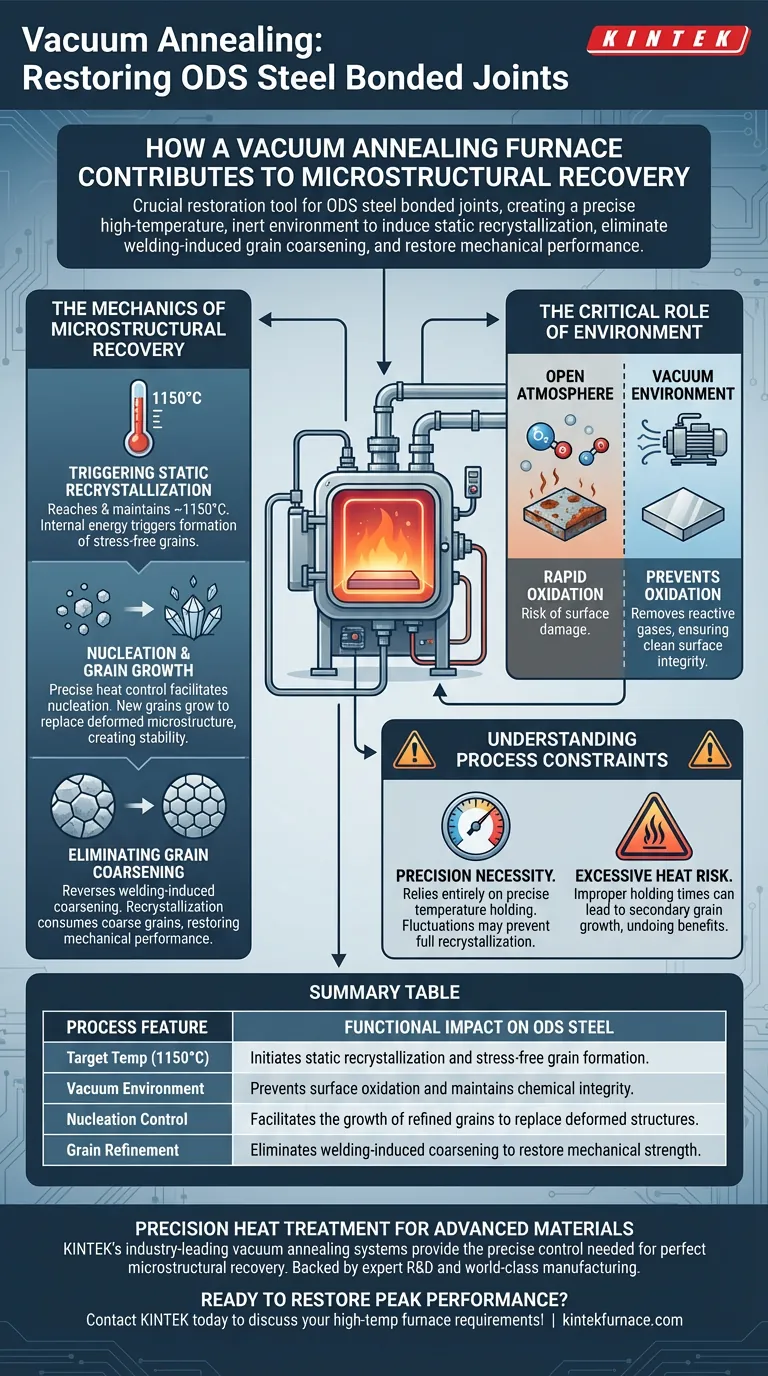

A vacuum annealing furnace acts as a critical restoration tool for ODS steel bonded joints by creating a precise high-temperature environment that induces static recrystallization. By holding the material at approximately 1150°C under a strict vacuum, the furnace enables the nucleation and growth of new grains while simultaneously preventing oxidation. This specific thermal process eliminates the grain coarsening introduced during welding and effectively restores the mechanical performance of the steel.

The core function of this process is to facilitate static recrystallization in a chemically inert environment. By reversing the structural damage caused by welding heat, specifically grain coarsening, the furnace returns the material to its optimal mechanical state.

The Mechanics of Microstructural Recovery

Triggering Static Recrystallization

The primary mechanism for recovery is static recrystallization. To initiate this, the furnace must reach and maintain a specific high-temperature threshold, typically around 1150°C.

At this thermal plateau, the internal energy of the cold-rolled samples is sufficient to trigger the formation of stress-free grains.

Nucleation and Grain Growth

The furnace utilizes precise temperature holding to control the microstructure's evolution. This controlled heat facilitates the nucleation of new grains within the material matrix.

Following nucleation, these new grains grow to replace the deformed microstructure, creating a more uniform and stable internal structure.

Eliminating Grain Coarsening

Welding processes inherently introduce significant heat, which typically leads to grain coarsening in the joint area. This coarsening degrades the mechanical properties of ODS steel.

The annealing process directly counteracts this by consuming the coarse grains through the recrystallization of new, refined grains. This restores the material's mechanical performance to pre-welding levels.

The Critical Role of Environment

Preventing Oxidation

While temperature drives the structural changes, the vacuum environment protects the material's surface integrity.

Heating steel to 1150°C in an open atmosphere would lead to rapid and severe oxidation. The vacuum furnace eliminates this risk by removing reactive gases, ensuring the surface remains clean and uncompromised during the long heating cycle.

Understanding Process Constraints

The Necessity of Precision

This process is not a generic heat treatment; it relies entirely on precise temperature holding.

If the temperature fluctuates or fails to reach the 1150°C target, static recrystallization may not initiate fully. Conversely, excessive heat or improper holding times could lead to secondary grain growth, potentially undoing the benefits of the treatment.

Making the Right Choice for Your Goal

To ensure successful microstructural recovery, consider your specific objectives:

- If your primary focus is Structural Restoration: Prioritize precise temperature control at 1150°C to ensure the complete elimination of coarse grains through recrystallization.

- If your primary focus is Surface Integrity: Ensure your vacuum system maintains a strict negative pressure environment to prevent any oxidation during the high-temperature cycle.

By strictly controlling both the thermal profile and the atmospheric environment, you transform a compromised welded joint back into a high-performance component.

Summary Table:

| Process Feature | Functional Impact on ODS Steel |

|---|---|

| Target Temp (1150°C) | Initiates static recrystallization and stress-free grain formation |

| Vacuum Environment | Prevents surface oxidation and maintains chemical integrity |

| Nucleation Control | Facilitates the growth of refined grains to replace deformed structures |

| Grain Refinement | Eliminates welding-induced coarsening to restore mechanical strength |

Precision Heat Treatment for Advanced Materials

Don't let welding-induced coarsening compromise the integrity of your ODS steel components. KINTEK’s industry-leading vacuum annealing systems provide the precise thermal control and high-vacuum environments necessary to achieve perfect microstructural recovery and static recrystallization.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of customizable Vacuum, Muffle, Tube, Rotary, and CVD systems designed to meet the most stringent laboratory and industrial requirements. Whether you are performing critical material restoration or developing next-generation alloys, our technical team is ready to tailor a solution to your unique needs.

Ready to restore your material's peak performance? Contact KINTEK today to discuss your high-temp furnace requirements!

Visual Guide

References

- José Rodolpho de Oliveira Leo, Michael E. Fitzpatrick. Development of a Diffusion Bonding Route for Joining Oxide-Dispersion-Strengthened (ODS) Steels for Nuclear Applications. DOI: 10.1007/s11661-023-07288-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a constant temperature heating device work with a vacuum chamber for graphene? Master Degradation Testing

- What are the advantages of using vacuum furnaces? Achieve Superior Metallurgical Control and Purity

- What is the role of inert gas in a vacuum furnace? Unlock Rapid, Controlled Cooling for Superior Metallurgy

- What is the container called in a crucible furnace? Choose the Right Crucible Material

- How does vacuum heat treatment benefit magnetic materials? Enhance Purity and Performance for Superior Results

- What are the two primary configurations of vacuum furnaces? Hot Wall vs. Cold Wall Explained

- What is the significance of vacuum degree in vacuum sintering furnaces? Optimize Material Purity and Performance

- How does a vacuum distillation system achieve the separation of titanium? Advanced Metal Refining Insights