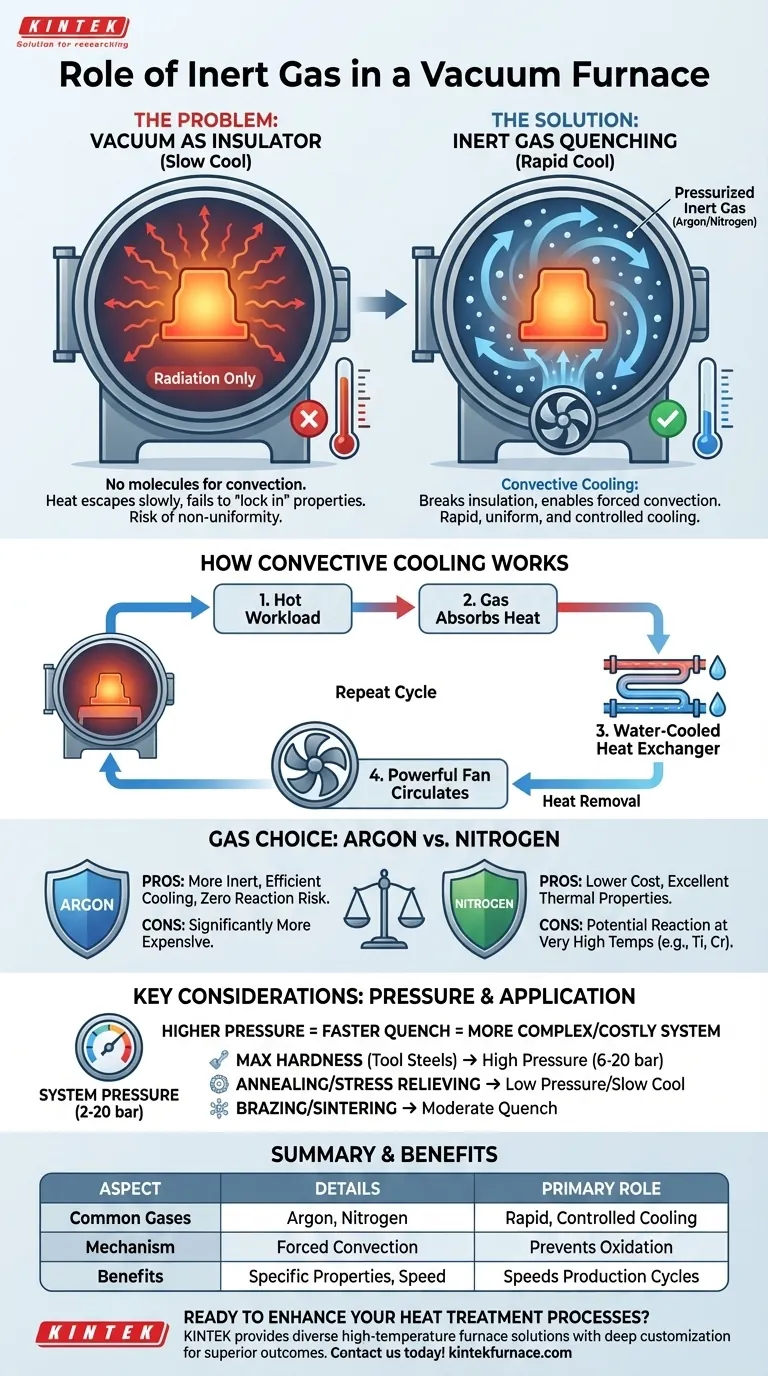

At its core, the primary role of an inert gas in a vacuum furnace is to serve as a medium for rapid, controlled cooling, a process known as gas quenching. After a part is heated in the vacuum to prevent oxidation, the vacuum environment, being a poor conductor of heat, cannot cool the part quickly enough. An inert gas like argon or nitrogen is therefore introduced under pressure to actively draw heat away from the part and achieve specific metallurgical properties.

A vacuum furnace is designed to create a perfectly clean heating environment. The fundamental challenge, however, is that a vacuum is also a thermal insulator. Inert gas is the tool used to overcome this insulation, enabling rapid and controlled cooling once the heating phase is complete.

The Fundamental Challenge: Heat Transfer in a Vacuum

To understand the role of inert gas, you must first understand the environment it operates in. A vacuum furnace is built around a single principle: removing the atmosphere.

Why a Vacuum is Necessary

At high temperatures, the oxygen and other reactive gases in normal air will aggressively react with a metal's surface. This causes oxidation (scaling) and contamination, which can ruin the part's integrity and surface finish.

By pumping the air out, the furnace creates a near-perfectly clean environment for heat-treating processes.

The Cooling Dilemma

The very thing that makes a vacuum ideal for clean heating—the absence of gas molecules—makes it terrible for cooling. Heat can only escape a hot part in a vacuum through radiation, which is a slow and often non-uniform process.

For many metallurgical processes, slow cooling is unacceptable. It fails to "lock in" the desired microstructure needed for hardness and strength.

Inert Gas as the Solution: The Quenching Mechanism

Introducing an inert gas breaks the vacuum's insulating effect and allows for rapid, forced-convection cooling.

Introducing the Cooling Agent

After the heating cycle is complete, the furnace chamber is rapidly backfilled with a high-purity inert gas, most commonly argon or nitrogen. This gas is "inert," meaning it will not chemically react with the hot metal.

How Convective Cooling Works

The quenching process is a closed-loop system. A powerful fan circulates the pressurized gas at high velocity through the hot zone.

The gas absorbs thermal energy from the hot workload. It is then immediately directed out of the hot zone and through a water-cooled heat exchanger, which removes the heat from the gas.

This newly cooled gas is then circulated back into the chamber to absorb more heat. This cycle repeats until the part reaches the target temperature.

The Benefit: Speed and Control

This method allows for cooling rates hundreds of times faster than cooling in a vacuum alone. By controlling the gas pressure and fan speed, operators can precisely manage the cooling curve to achieve specific, repeatable material properties. This control also leads to faster overall production cycle times.

Understanding the Trade-offs

While essential, the choice and use of inert gas involve important considerations that affect both the process outcome and operational cost.

Gas Type: Argon vs. Nitrogen

Argon is heavier and more purely inert than nitrogen, providing slightly more efficient cooling and zero risk of reaction. However, it is significantly more expensive.

Nitrogen is the most common choice due to its lower cost and excellent thermal properties. For most standard steels and alloys, it is perfectly suitable. At very high temperatures, however, it can react with certain elements (like titanium or chromium) to form undesirable nitrides on the part's surface.

System Pressure and Complexity

Gas quenching systems are rated by their pressure, typically from 2 to 20 bar (twice to twenty times atmospheric pressure). Higher pressure means more gas molecules, which provides a more intense and rapid quench.

However, a higher-pressure system requires a more robust furnace chamber, a more powerful fan, and a larger heat exchanger, adding significant cost and complexity to the equipment.

Making the Right Choice for Your Goal

Your quenching strategy depends entirely on the metallurgical outcome you need to achieve.

- If your primary focus is maximum hardness for tool steels: You need a high-pressure (6-20 bar) quench to cool the material fast enough to form a fully martensitic structure.

- If your primary focus is annealing or stress relieving: A slow vacuum cool or a gentle, low-pressure fan cool is often sufficient and more cost-effective.

- If your primary focus is brazing or sintering: A moderate quench is typically used to solidify the braze alloy quickly or to reduce cycle time without thermally shocking the components.

Ultimately, understanding the function of inert gas is key to mastering the vacuum furnace and precisely controlling the final properties of your components.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Role | Rapid, controlled cooling (gas quenching) in vacuum furnaces |

| Common Gases | Argon (more inert, efficient cooling) and Nitrogen (cost-effective, widely used) |

| Cooling Mechanism | Forced convection with pressurized gas circulation and heat exchange |

| Key Benefits | Prevents oxidation, achieves specific metallurgical properties, speeds up production cycles |

| Considerations | Gas type affects cost and reactivity; higher pressure systems increase complexity and expense |

Ready to enhance your heat treatment processes with advanced vacuum furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior metallurgical outcomes. Contact us today to discuss how our tailored solutions can optimize your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing