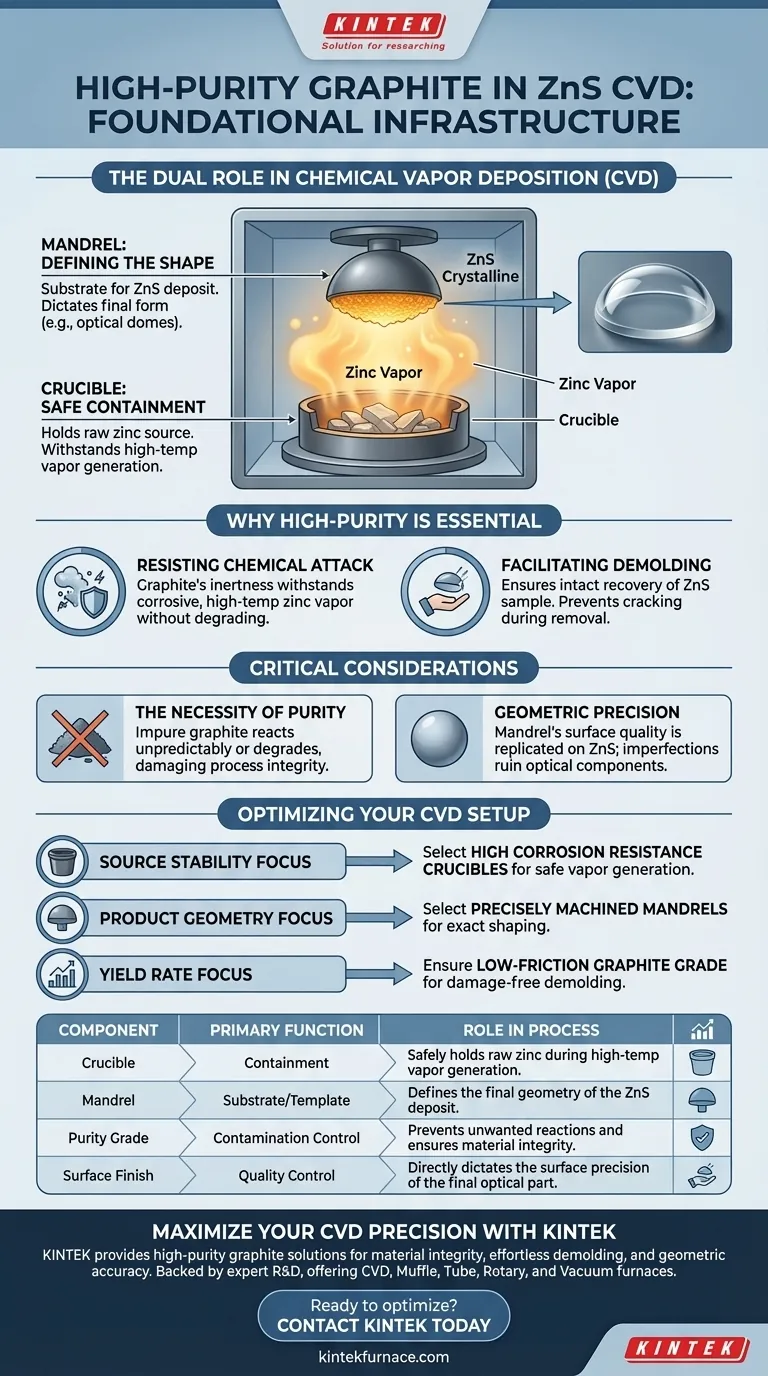

High-purity graphite components act as the foundational infrastructure for the Chemical Vapor Deposition (CVD) of Zinc Sulfide (ZnS). They function simultaneously as robust containment vessels for the raw zinc source and as precision-engineered substrates, or mandrels, upon which the ZnS material is deposited and grown.

By withstanding the corrosive environment of high-temperature zinc vapor, these graphite components ensure the structural integrity of the process while defining the final geometry of the ZnS product.

The Dual Role of Graphite in CVD

The Crucible: Safe Containment

In the CVD process, crucibles serve as the primary holding vessels for the raw zinc source material.

They must maintain structural integrity while the zinc is heated to generate the vapor required for the reaction.

The Mandrel: Defining the Shape

The mandrel acts as the physical substrate where the chemical reaction culminates.

ZnS deposits directly onto this surface, meaning the mandrel dictates the final form of the material.

This capability allows manufacturers to produce specific, complex geometries, such as the hemispherical domes often required for optical applications.

Why High-Purity Graphite is Essential

Resisting Chemical Attack

The CVD environment for ZnS involves exposure to high-temperature zinc vapor, which is chemically aggressive.

High-purity graphite is essential because it possesses the chemical inertness required to withstand this corrosion without degrading.

Facilitating Demolding

A critical measure of success in CVD is the ability to recover the finished product intact.

Graphite properties facilitate the easy demolding of the finished ZnS sample.

This ensures that the deposited material can be separated from the mandrel without cracking or sustaining damage.

Critical Considerations for Component Selection

The Necessity of Purity

The requirement for "high-purity" graphite is not merely a suggestion; it is a functional prerequisite.

Impure graphite can react unpredictably with the zinc vapor or degrade prematurely under thermal stress.

Geometric Precision

Because the mandrel acts as a mold, its surface quality directly translates to the deposited ZnS.

Any imperfections in the graphite substrate will be replicated in the final optical component.

Optimizing Your CVD Setup

To ensure successful ZnS deposition, select graphite components based on the specific phase of the process you need to control.

- If your primary focus is Source Stability: Prioritize graphite crucibles with high corrosion resistance to safely contain the zinc vapor generation.

- If your primary focus is Product Geometry: Select graphite mandrels machined to exact specifications to ensure precise shaping of components like hemispherical domes.

- If your primary focus is Yield Rate: Ensure the graphite grade used allows for low-friction demolding to prevent damaging the crystal during removal.

High-purity graphite ultimately bridges the gap between raw chemical potential and a finished, precision-shaped optical material.

Summary Table:

| Component | Primary Function | Role in Process |

|---|---|---|

| Crucible | Containment | Safely holds raw zinc during high-temp vapor generation |

| Mandrel | Substrate/Template | Defines the final geometry (e.g., domes) of the ZnS deposit |

| Purity Grade | Contamination Control | Prevents unwanted reactions and ensures material integrity |

| Surface Finish | Quality Control | Directly dictates the surface precision of the final optical part |

Maximize Your CVD Precision with KINTEK

High-performance ZnS deposition requires more than just high temperatures—it demands material integrity. KINTEK provides high-purity graphite solutions designed to withstand aggressive chemical environments while ensuring effortless demolding and geometric accuracy.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp systems, including CVD, Muffle, Tube, Rotary, and Vacuum furnaces, all customizable for your unique research and production needs.

Ready to optimize your deposition process? Contact KINTEK today to discuss your custom project requirements!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does the CVD process begin? Master Precise Film Deposition from the Start

- Why are high-purity hydrogen and argon necessary for hBN thin film LPCVD? Master Gas Roles for Superior Growth

- How does precise temperature control impact the CVD process? Unlock Superior Thin Film Quality

- Why is a high-vacuum thermal evaporation system required for gold back electrodes? Ensure Pure, High-Efficiency Contacts

- What role does a vacuum thermal evaporation system play in the fabrication of Cu13Se52Bi35 thin films? Expert Guide

- What are the benefits of using a CVD furnace? Achieve Atomic-Level Control for Superior Thin Films

- What is Chemical Vapor Deposition (CVD) and what is it used for? Unlock High-Performance Thin Films

- What challenges are associated with CVD? Overcome Cost, Control, and Safety Hurdles