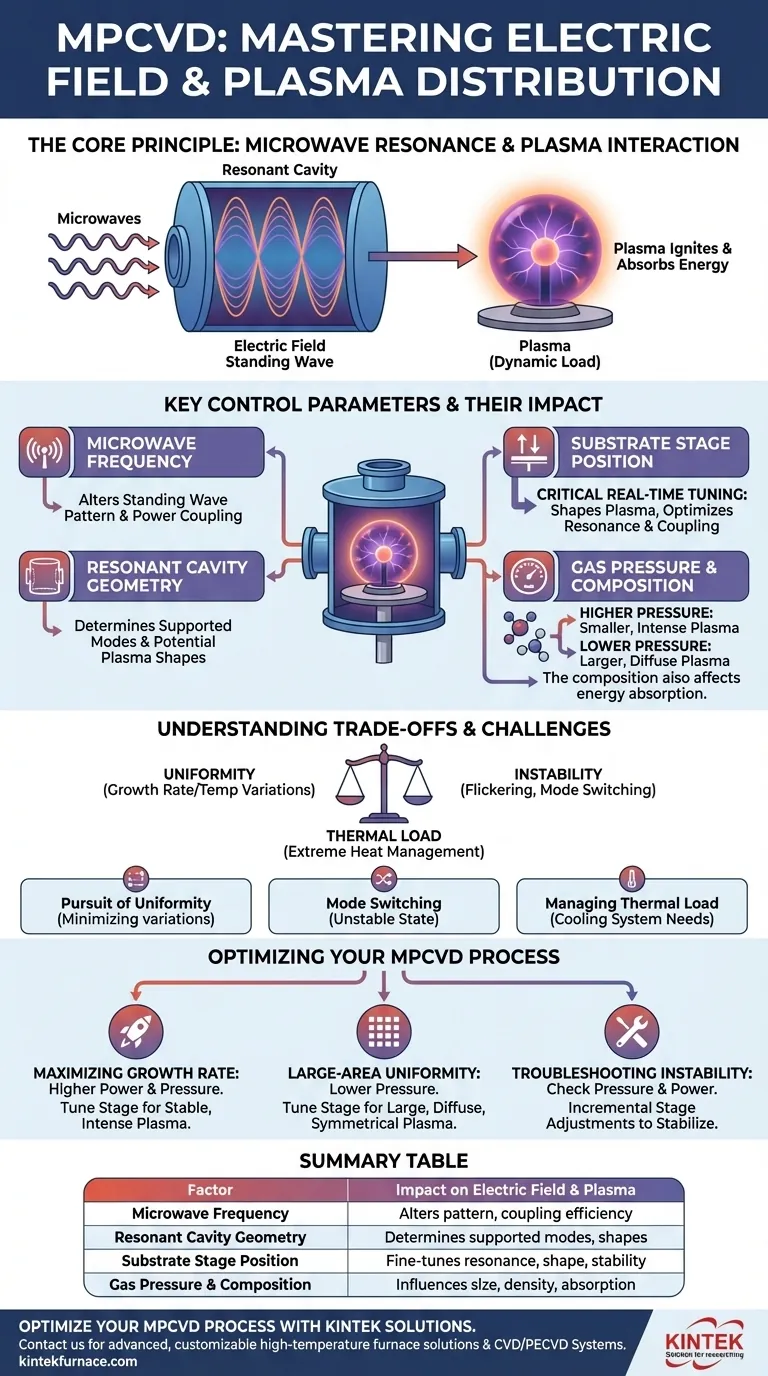

In any MPCVD system, the distribution of the electric field and the resulting plasma shape are governed by a handful of critical, interacting parameters. The most significant factors are the microwave frequency, the physical geometry of the resonant cavity, the position of the substrate stage, and the operating gas pressure. Adjusting these variables allows an operator to control how microwave energy couples into the gas, thereby shaping the plasma for optimal material deposition.

The core challenge in MPCVD is that the plasma is not a passive element; it is a dynamic load. While the initial electric field determines where the plasma ignites, the plasma's presence immediately absorbs energy and alters that field. Mastering the process means manipulating the system's parameters to create a stable, self-sustaining plasma shape that is optimized for uniform growth.

The Core Principle: Microwave Resonance and Plasma Interaction

To effectively control an MPCVD system, you must first understand the fundamental physics at play. The process is a constant interplay between the electromagnetic field and the plasma it creates.

Establishing the Electric Field

The process begins with microwaves being fed into a cylindrical or rectangular chamber, known as a resonant cavity. These microwaves form a standing wave pattern, creating a predictable, stationary map of electric field intensity. This pattern is defined by specific resonant modes, such as the commonly used TM₀₁₃ (Transverse Magnetic) mode in cylindrical cavities.

Plasma Ignition

The standing wave has points of maximum electric field strength (antinodes). When process gas is introduced at a specific pressure, the electric field at these antinodes can become strong enough to strip electrons from the gas atoms. This event, called dielectric breakdown, ignites the plasma.

The Plasma as a Dynamic Load

Once ignited, the plasma is highly conductive and begins to absorb a significant amount of the microwave energy. This absorption fundamentally changes the conditions inside the cavity. The electric field pattern is no longer the "empty cavity" mode; it is now distorted by the presence of the plasma itself. The goal of tuning is to manage this new, "loaded" state to create a stable plasma with the desired characteristics.

Key Control Parameters and Their Impact

Each parameter you can adjust directly influences the resonant conditions of the cavity and the resulting plasma.

Microwave Frequency

The frequency of the microwaves (e.g., 2.45 GHz) dictates their wavelength. The resonant cavity's dimensions are designed around this specific wavelength to support desired modes. Even minor shifts in frequency can alter the standing wave pattern, moving the location of the electric field maximums and changing where power is most efficiently delivered to the plasma.

Resonant Cavity Geometry

The physical size—the diameter and height—of the cavity is the most fundamental factor. These dimensions determine which resonant modes the cavity can naturally support. While not typically adjusted during a run, the cavity's design is the primary determinant of the potential plasma shapes and sizes the system can achieve.

Substrate Stage Position

This is the most critical real-time tuning parameter. The substrate sits on a stage that can be moved vertically. Adjusting the stage's height effectively changes the internal height of the resonant cavity. This allows the operator to fine-tune the resonance to ensure maximum power is coupled into the plasma and to physically shape the plasma ball. Raising the stage can compress the plasma, increasing its density, while lowering it allows the plasma to expand.

Gas Pressure and Composition

The pressure inside the chamber directly influences the plasma's size and density.

- Higher pressure confines the plasma, causing it to shrink into a smaller, more intense "ball" located in the region of the highest electric field strength.

- Lower pressure allows the plasma to expand, creating a larger, more diffuse discharge that can cover a wider area.

The chemical composition of the gas (e.g., the ratio of methane to hydrogen for diamond growth) also changes the plasma's electrical properties, affecting how efficiently it absorbs microwave energy.

Understanding the Trade-offs and Challenges

Tuning an MPCVD system is a balancing act where optimizing one characteristic can negatively impact another.

The Pursuit of Uniformity

The ultimate goal for most applications is a perfectly uniform deposition across the entire substrate. However, the inherent nature of resonant modes means the electric field is never perfectly uniform. This leads to temperature and growth rate variations, which must be minimized through careful tuning of the stage position and pressure.

Mode Switching and Instability

Under certain power and pressure combinations, the plasma can become unstable. It may flicker, change shape, or "jump" to a different location within the cavity (mode switching). This is catastrophic for controlled growth and indicates that the system is operating in an unstable resonant state that must be tuned out.

Managing Thermal Load

An intense, dense plasma generates extreme heat. The plasma's size, shape, and proximity to the substrate directly influence the substrate's temperature. This thermal load must be managed precisely, as deposition chemistry is highly sensitive to temperature. The plasma shape you choose impacts the cooling system you need.

Optimizing Your MPCVD Process

Your approach to tuning should be dictated by your end goal. Use the following guidelines to inform your adjustments.

- If your primary focus is maximizing growth rate: You will likely need to operate at higher power and pressure. This requires careful tuning of the substrate stage to maintain a stable, intense plasma ball centered over your sample.

- If your primary focus is achieving large-area uniformity: You will benefit from operating at lower pressures to create a larger, more diffuse plasma and meticulously tuning the stage position to ensure the plasma is symmetrical and stable.

- If your primary focus is troubleshooting an unstable plasma: First, analyze your pressure and power settings. Then, make small, incremental adjustments to the substrate stage height to guide the system back into a stable resonant condition.

By understanding how these factors interact, you can move from simply operating the system to intelligently controlling it for repeatable, high-quality results.

Summary Table:

| Factor | Impact on Electric Field & Plasma |

|---|---|

| Microwave Frequency | Alters standing wave pattern and power coupling efficiency |

| Resonant Cavity Geometry | Determines supported resonant modes and plasma shapes |

| Substrate Stage Position | Fine-tunes resonance and plasma shape for stability and uniformity |

| Gas Pressure & Composition | Influences plasma size, density, and energy absorption |

Optimize Your MPCVD Process with KINTEK Solutions

Struggling with plasma instability or non-uniform deposition in your MPCVD system? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Let us help you achieve stable, efficient plasma control and superior material growth—contact us today to discuss how our expertise can benefit your research!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability