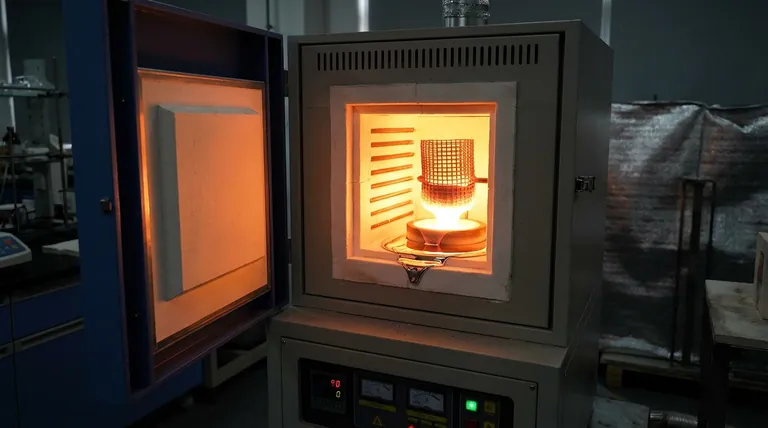

A high-temperature vacuum resistance furnace provides two critical technical conditions for simulating infiltration: a thermal capacity reaching 1600 °C and a high vacuum environment below 5×10⁻⁵ Torr. These specific parameters are engineered to replicate the rigorous production processes required for manufacturing nuclear fusion components.

By eliminating atmospheric contamination, the furnace ensures that the movement of molten steel into tungsten meshes is driven solely by physical laws—specifically capillary forces—rather than chemical reactions like oxidation.

The Role of Environmental Control

To accurately simulate the infiltration of molten steel into tungsten, you must isolate the materials from external variables. The furnace achieves this through specific thermal and atmospheric controls.

Reaching the Melting Point

The furnace is capable of sustaining temperatures up to 1600 °C.

This extreme heat is necessary to fully melt the steel and bring the tungsten mesh to the correct processing temperature. It ensures the viscosity of the molten fluid is correct for infiltration.

Eliminating Oxidation Risks

The most critical function of the furnace is maintaining a vacuum level below 5×10⁻⁵ Torr.

At elevated temperatures, both tungsten and iron are highly susceptible to oxidation. Even trace amounts of oxygen can form oxide layers on the metal surfaces, which would ruin the experiment.

Ensuring Pure Capillary Action

The combination of high heat and high vacuum creates a pristine environment for the melt to spread.

Because oxidation is prevented, the infiltration of the steel into the tungsten mesh is governed entirely by capillary forces and inherent wettability. This allows researchers to observe the mechanical interactions exactly as they would occur in a perfect production scenario.

Critical Dependencies and Risks

While the furnace provides the necessary conditions, the validity of the simulation relies on the strict maintenance of these parameters.

Sensitivity to Vacuum Fluctuation

The success of the simulation is binary; it depends entirely on the integrity of the vacuum.

If the pressure rises above 5×10⁻⁵ Torr, oxidation will occur immediately. This alters the surface chemistry of the tungsten, changing how the steel wets the surface and rendering the simulation data inaccurate.

Thermal Stability Requirements

Achieving 1600 °C is not enough; the temperature must be stable to ensure consistent fluidity.

If the temperature fluctuates significantly, the viscosity of the molten steel will change. This impacts the speed and depth of infiltration, leading to results that do not accurately reflect the capillary potential of the materials.

Making the Right Choice for Your Simulation

To ensure your infiltration experiments yield valid data for nuclear fusion applications, prioritize your setup based on these goals:

- If your primary focus is Material Purity: Ensure your vacuum system can consistently hold pressures below 5×10⁻⁵ Torr throughout the entire heating cycle to prevent oxide formation.

- If your primary focus is Infiltration Mechanics: Verify the furnace can sustain 1600 °C without fluctuation to ensure the melt spreads solely via capillary forces.

Ultimately, the accuracy of your simulation depends on the furnace's ability to remove chemical interference and isolate the physical interactions between the metals.

Summary Table:

| Technical Parameter | Target Specification | Critical Role in Simulation |

|---|---|---|

| Operating Temperature | Up to 1600 °C | Ensures complete steel melting and optimal fluid viscosity. |

| Vacuum Level | < 5×10⁻⁵ Torr | Prevents oxidation of tungsten and iron to maintain material purity. |

| Infiltration Driver | Capillary Action | Enabled by the absence of chemical interference in a vacuum. |

| Application Focus | Nuclear Fusion | Replicates conditions for manufacturing high-performance components. |

Achieve Unmatched Precision in Your High-Temp Research

Don't let oxidation or thermal instability compromise your material simulations. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our diverse range of Muffle, Tube, Rotary, Vacuum, and CVD systems are engineered for rigorous performance and are fully customizable to meet your unique laboratory needs.

Whether you are simulating molten metal infiltration or developing advanced nuclear fusion components, KINTEK ensures your results are driven by science, not environmental variables.

Ready to upgrade your lab's capabilities? Contact KINTEK today for a customized solution!

References

- N. S. Popov, Oleg Sevryukov. Interaction of iron melt with tungsten and WFe composite structure evolution. DOI: 10.3897/nucet.10.129596

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the benefits of low pressure carburizing in terms of metal quality? Boost Fatigue Strength and Reliability

- What are the main heat treatment processes used in high-temperature vacuum furnaces? Achieve Superior Material Properties

- What are the advantages of using vacuum furnaces in tool and die manufacturing? Boost Tool Longevity and Precision

- Why is a Vacuum Drying Oven necessary for KF-NaF-AlF3 electrolytes? Prevent Hydrolysis and Corrosion

- What type of pumping systems are used in high vacuum furnaces? Essential Guide for Clean and Efficient Processing

- How does vacuum level control affect ceramic sintering? Master High-Precision Material Performance

- Why is a vacuum degassing system required for BET testing? Ensure Reliable Catalyst Surface Area Analysis

- What is the function of a laboratory vacuum drying oven in catalyst and electrode treatment? Ensure Material Integrity