The control of vacuum levels in a high-precision furnace is the decisive factor in determining the structural integrity and chemical purity of sintered ceramics. By maintaining a stable ultra-low pressure environment, you effectively remove oxygen and moisture, which is essential for preventing oxidation in non-oxide ceramics and eliminating closed pores to achieve theoretical density.

The core value of vacuum control lies in its ability to isolate the material from atmospheric interference. By eliminating gas resistance and reactive elements, you transition from simple heating to precise material synthesis, enabling properties like optical translucency and maximum mechanical strength.

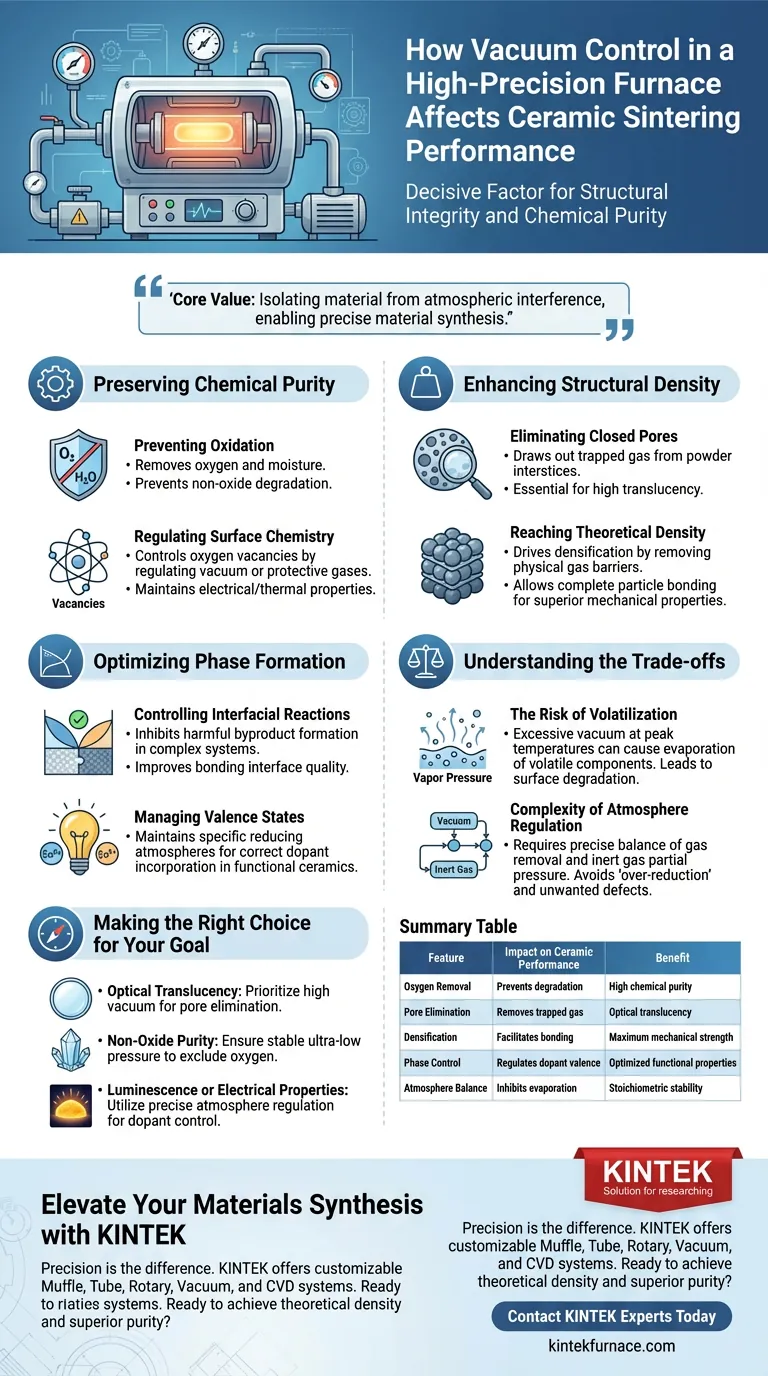

Preserving Chemical Purity

Preventing Oxidation

For non-oxide ceramics, such as nitrides and carbides, the presence of oxygen at high temperatures is detrimental.

A high-precision vacuum environment removes residual oxygen and moisture from the sintering atmosphere.

This prevents the raw materials from reacting with oxygen, ensuring the synthesized material retains its intended chemical composition without degradation.

Regulating Surface Chemistry

Precise atmosphere control does more than just remove air; it actively regulates the chemical state of the ceramic.

By controlling the vacuum or introducing specific protective gases, you can regulate the oxygen vacancy concentration within the ceramic body.

This prevents unnecessary oxidation or reduction reactions at the grain boundaries, which is critical for maintaining the material's electrical or thermal properties.

Enhancing Structural Density

Eliminating Closed Pores

One of the primary challenges in ceramic sintering is the entrapment of gas within the material, leading to porosity.

The vacuum environment assists in drawing gases out of the powder interstices and eliminating closed pores deep within the material.

This process is essential for materials that require high translucency, as trapped pores scatter light and reduce optical quality.

Reaching Theoretical Density

To achieve maximum strength and performance, a ceramic must approach its theoretical density.

Vacuum sintering drives the densification process by removing the physical barrier of trapped gas.

This allows particles to bond more completely, resulting in a denser, more uniform microstructure with superior mechanical properties.

Optimizing Phase Formation

Controlling Interfacial Reactions

In complex material systems, such as aluminum alloy matrices, uncontrolled reactions can form harmful byproducts like aluminum carbide.

A high vacuum environment (e.g., 5×10⁻² Pa) helps inhibit the excessive formation of these interfacial reaction products.

This control is decisive for improving the quality of the bonding interface and the overall density of the composite.

Managing Valence States

For advanced functional ceramics, such as luminescent materials, the valence state of dopant ions is critical.

While high vacuum removes gases, high-precision furnaces can also maintain specific reducing atmospheres (e.g., H2/N2 mixtures).

This ensures dopants like europium are incorporated into the lattice in the correct state (e.g., Eu2+), directly determining the material's performance.

Understanding the Trade-offs

The Risk of Volatilization

While high vacuum is excellent for densification, it can be a double-edged sword for materials with high vapor pressures.

If the vacuum level is uncontrolled or excessive at peak temperatures (1050°C to 1400°C), volatile components of the ceramic matrix may evaporate.

This can lead to surface degradation or a shift in stoichiometry, negatively affecting the material's final properties.

Complexity of Atmosphere Regulation

Achieving the perfect balance often requires more than just a vacuum pump; it demands flexible airflow regulation.

You must balance the need for gas removal (vacuum) with the potential need for a partial pressure of inert gas (Argon or Nitrogen) to suppress decomposition.

Failure to precisely regulate this balance can result in "over-reduction," creating unwanted defects in the crystal structure.

Making the Right Choice for Your Goal

To maximize the performance of your ceramic materials, align your furnace settings with your specific material requirements:

- If your primary focus is Optical Translucency: Prioritize high vacuum levels to aggressively eliminate closed pores and maximize density.

- If your primary focus is Non-Oxide Purity: Ensure your system can maintain a stable ultra-low pressure environment to completely exclude oxygen and moisture.

- If your primary focus is Luminescence or Electrical Properties: utilize a furnace with precise atmosphere regulation to maintain the correct reducing environment for dopant valence control.

Precision in vacuum control is not just about removing air; it is about engineering the perfect environment for your material to reach its theoretical limits.

Summary Table:

| Feature | Impact on Ceramic Performance | Benefit |

|---|---|---|

| Oxygen Removal | Prevents degradation of non-oxide ceramics | High chemical purity |

| Pore Elimination | Removes gas trapped in powder interstices | Optical translucency |

| Densification | Facilitates complete particle bonding | Maximum mechanical strength |

| Phase Control | Regulates dopant valence states | Optimized functional properties |

| Atmosphere Balance | Inhibits volatile component evaporation | Stoichiometric stability |

Elevate Your Materials Synthesis with KINTEK

Precision is the difference between a failed experiment and a breakthrough. At KINTEK, we understand that high-performance ceramics require uncompromising control over vacuum and atmosphere.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need to eliminate closed pores for optical clarity or regulate valence states for advanced luminescence, our lab high-temp furnaces are fully customizable to meet your unique research and production needs.

Ready to achieve theoretical density and superior purity in your materials?

Visual Guide

References

- Adeleke Abdulrahman Oyekanmi, Monzur Alam Imteaz. A novel oyster shell biocomposite for the efficient adsorptive removal of cadmium and lead from aqueous solution: Synthesis, process optimization, modelling and mechanism studies. DOI: 10.1371/journal.pone.0294286

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of titanium scraps in vacuum systems for HTGN? Boost Nitriding Depth with Oxygen Getters

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision

- What are the key steps in vacuum brazing? Master the 5-Step Process for Strong, Clean Joints

- What are the main features and advantages of a vacuum heat treatment furnace? Achieve Superior Material Quality & Efficiency

- What are the key advantages of using a vacuum arc furnace? Achieve Unmatched Purity and Performance

- What is the function of a high-vacuum furnace in tantalum carburization? Purity & Reaction Precision

- What is the primary function of a vacuum arc melting furnace? Expert Solutions for High-Entropy Alloy Production

- Why is a vacuum environment essential when using a Spark Plasma Sintering (SPS) furnace for Ti64-Si3N4-ZrO2? Achieve Optimal Density & Purity