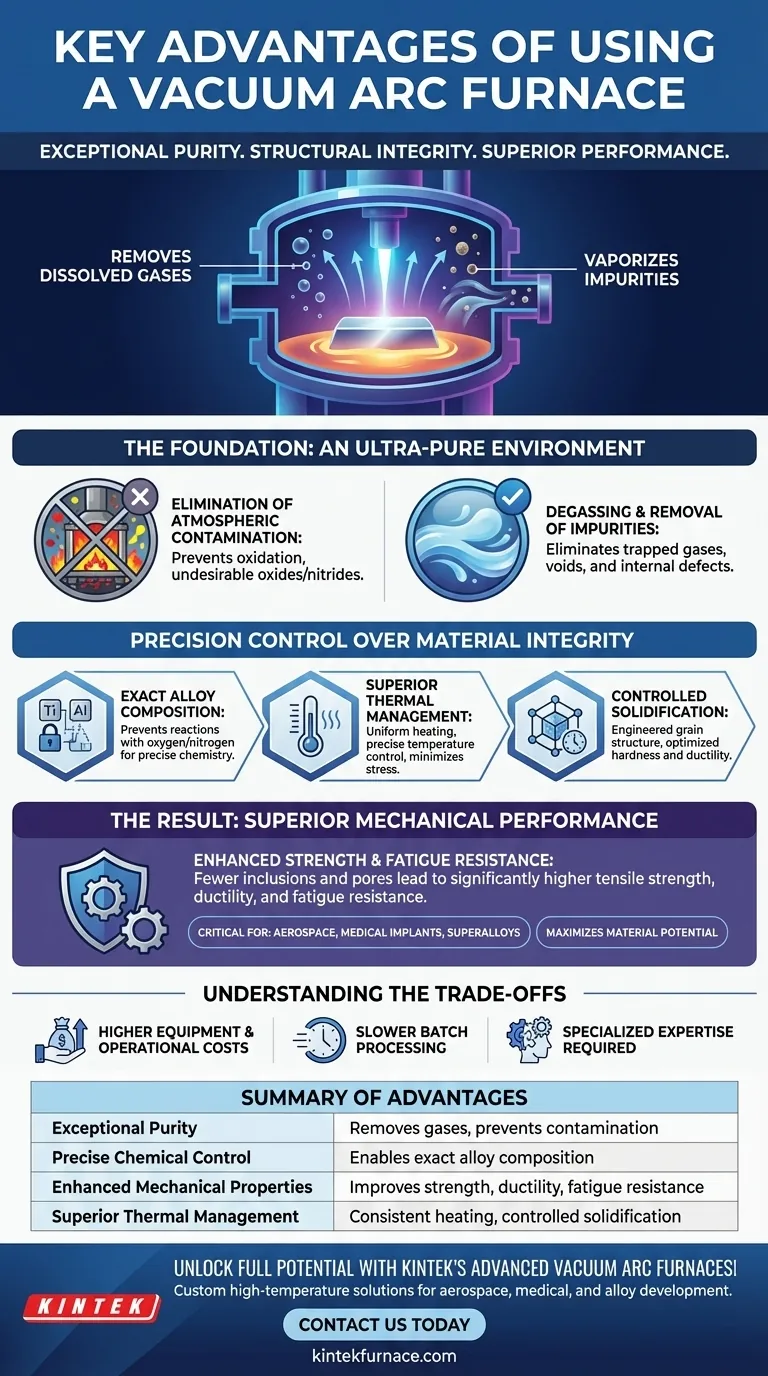

The primary advantage of a vacuum arc furnace is its ability to produce materials of exceptional purity and structural integrity. By melting metals and alloys in a controlled vacuum, this process removes dissolved gases and vaporizes undesirable impurities, resulting in a final product with superior cleanliness, precise chemical composition, and enhanced mechanical properties that are unattainable with conventional air-melting techniques.

A vacuum arc furnace is not merely a tool for melting metal; it is a sophisticated refining and purification system. Its core function is to create an ultra-clean environment that eliminates atmospheric contamination and actively removes internal impurities, fundamentally improving the quality and performance of high-specification materials.

The Foundation: An Ultra-Pure Environment

The defining characteristic of a vacuum arc furnace is the environment it creates. This controlled vacuum is the source of its most significant advantages.

Elimination of Atmospheric Contamination

In traditional furnaces, the molten metal is exposed to air, which is primarily nitrogen and oxygen. These reactive gases can form undesirable oxides and nitrides within the material.

A vacuum furnace removes the atmosphere, creating a contamination-free environment. This prevents oxidation and other reactions, ensuring the intrinsic properties of the metal are preserved.

Degassing and Removal of Impurities

Many metals contain dissolved gases like hydrogen, nitrogen, and oxygen from prior processing. These gases become trapped during solidification, creating voids and internal defects that compromise strength.

The low-pressure environment of a vacuum furnace causes these dissolved gases to be drawn out of the molten metal. It also vaporizes and removes other tramp elements with high vapor pressures, acting as a powerful purification process.

Precision Control Over Material Integrity

Beyond creating a clean slate, the vacuum environment enables an unparalleled level of control over the entire melting and solidification process.

Exact Alloy Composition

When adding sensitive alloying elements like titanium or aluminum, a vacuum prevents them from reacting with oxygen or nitrogen.

This ensures the final chemical composition of the alloy is precisely what was intended. This level of accuracy is critical for superalloys and other high-performance materials where minor variations can drastically alter performance.

Superior Thermal Management

Vacuum furnaces provide highly uniform heating and precise temperature control. This consistency minimizes thermal stresses and reduces the risk of defects forming during the melt.

The process is often computer-controlled, ensuring exceptional metallurgical repeatability from one batch to the next.

Controlled Solidification

The technology also allows for the rapid cooling, or quenching, of the material. By carefully managing the solidification process, metallurgists can engineer a specific grain structure to achieve desired mechanical properties like hardness or ductility.

The Result: Superior Mechanical Performance

The combination of high purity and precise process control directly translates into materials with demonstrably better performance characteristics.

Enhanced Strength and Fatigue Resistance

The final product from a vacuum arc furnace has far fewer inclusions, gas pores, and other microscopic defects. These defects are the typical initiation points for cracks.

By eliminating them, the material exhibits significantly higher tensile strength, ductility, and fatigue resistance. This is essential for components that must withstand extreme stress and cyclical loading, such as turbine blades or medical implants.

Understanding the Trade-offs

While the advantages are significant, a vacuum arc furnace is a specialized tool with specific considerations.

Higher Equipment and Operational Costs

Vacuum arc furnaces represent a significant capital investment and have higher operational costs compared to conventional air-melt furnaces due to the complexity of the vacuum systems and controls.

Slower Batch Processing

The overall cycle time, which includes loading, drawing the vacuum, melting, and cooling, can be longer than for simpler melting processes. This makes it less suitable for high-volume, low-cost commodity metals.

Specialized Expertise Required

Operating and maintaining a vacuum arc furnace requires highly skilled technicians and engineers who understand both metallurgy and high-vacuum technology.

Making the Right Choice for Your Application

Selecting this technology is a strategic decision driven by the end-use requirements of the material.

- If your primary focus is mission-critical components (aerospace, medical): The unparalleled purity and fatigue resistance are non-negotiable benefits that justify the cost.

- If your primary focus is developing novel superalloys: The precise control over alloy chemistry is essential for research and achieving target properties.

- If your primary focus is maximizing material performance: This process can refine even standard alloys to a much higher grade, unlocking their full potential.

Ultimately, choosing a vacuum arc furnace is a commitment to achieving the highest possible standard of material quality, ensuring reliability where failure is not an option.

Summary Table:

| Advantage | Description |

|---|---|

| Exceptional Purity | Removes dissolved gases and impurities in a vacuum, preventing contamination and oxidation. |

| Precise Chemical Control | Enables exact alloy composition by avoiding reactions with atmospheric gases. |

| Enhanced Mechanical Properties | Improves tensile strength, ductility, and fatigue resistance by eliminating defects. |

| Superior Thermal Management | Provides uniform heating and controlled solidification for consistent results. |

Unlock the full potential of your materials with KINTEK's advanced vacuum arc furnaces! Leveraging exceptional R&D and in-house manufacturing, we offer high-temperature solutions like Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more, with deep customization to meet your unique needs. Whether you're in aerospace, medical, or alloy development, our expertise ensures superior purity and performance. Contact us today to discuss how we can enhance your lab's capabilities!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification