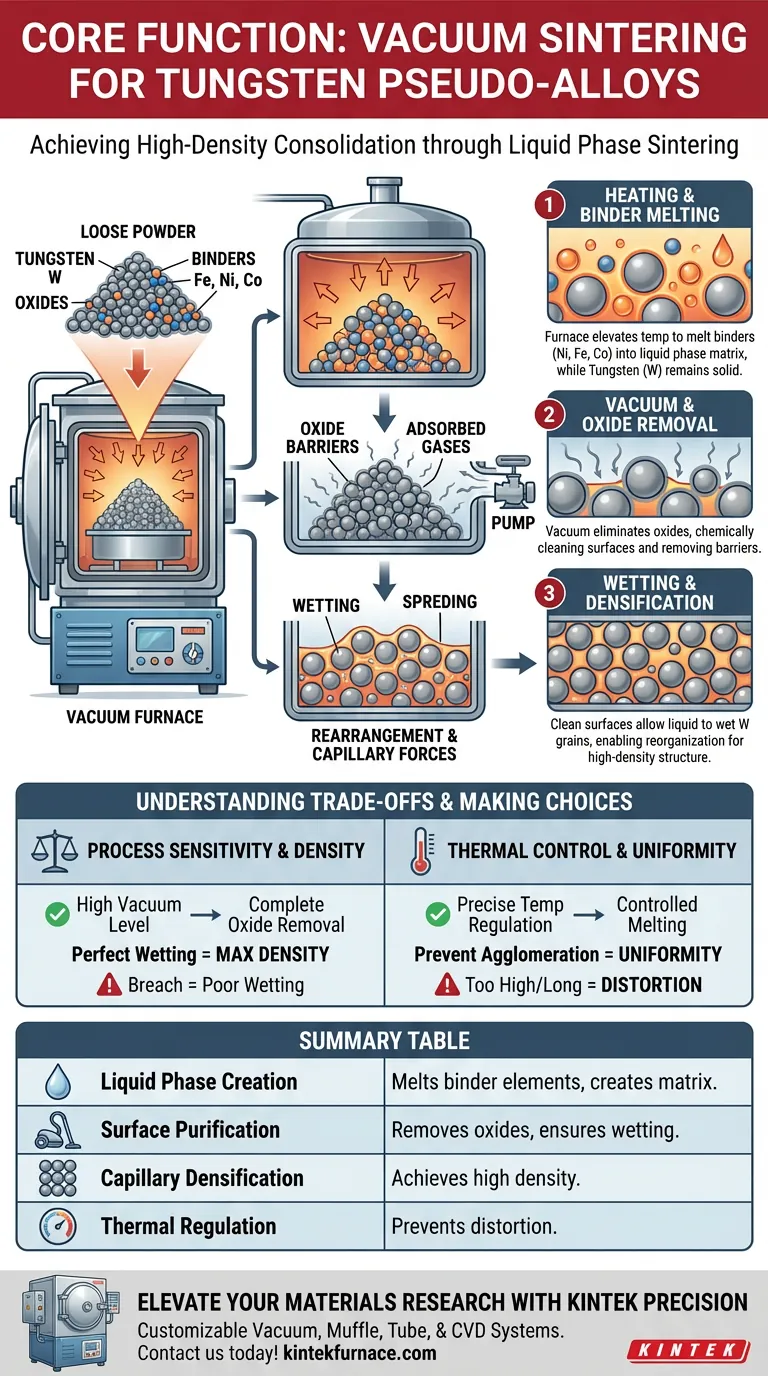

The core function of a Vacuum Sintering Furnace is to simultaneously generate a liquid matrix and purify the material surface to enable high-density consolidation. Specifically for Tungsten Pseudo-alloys, the furnace maintains a high-temperature environment that melts alloying elements—such as iron, nickel, and cobalt—while the vacuum actively removes chemical barriers like oxides. This dual process is essential for transforming loose powder into a solid, structurally sound component.

The furnace acts as both a thermal reactor and a cleaning agent; it melts the binder metals to create a liquid phase while stripping oxides from tungsten surfaces to ensure this liquid adheres perfectly to the grains.

The Mechanics of Liquid Phase Sintering

Creating the Liquid Phase Matrix

The furnace elevates the temperature specifically to reach the melting points of the binder metals (iron, nickel, and cobalt).

Unlike the tungsten, which remains solid, these elements melt to form a liquid phase matrix. This liquid surrounds the solid tungsten particles, acting as the medium through which the alloy consolidates.

Removing Chemical Barriers

Crucially, the vacuum environment eliminates adsorbed gases and oxides from the surface of the powder particles.

If these oxides were left in place, they would act as a barrier, preventing the liquid metal from touching the solid tungsten. The vacuum ensures the surfaces are chemically clean and reactive.

Promoting Wetting and Rearrangement

Once the oxides are removed, the liquid phase can effectively "wet" the tungsten particles.

This wetting action allows for the reorganization of particles, driven by capillary forces. The result is a highly densified structure where spherical tungsten grains are uniformly distributed within the solidified matrix.

Understanding the Trade-offs

Process Sensitivity

While vacuum sintering offers superior cleanliness, the process is highly sensitive to the quality of the vacuum.

Any breach or insufficient vacuum level will fail to remove oxides, leading to poor wetting and structural defects. The equipment requires rigorous maintenance to ensure the "perfect control" of the atmosphere is maintained.

Thermal Control vs. Distortion

Achieving the liquid phase requires precise temperature control.

If the temperature is too low, the matrix will not melt sufficiently to densify the part. If the temperature is too high or held too long, the component may suffer from shape distortion due to excessive liquid flow.

Making the Right Choice for Your Project

To maximize the quality of your Tungsten Pseudo-alloys, align your furnace parameters with your specific material goals:

- If your primary focus is maximum density: Prioritize a high-vacuum level to ensure complete oxide removal, which guarantees the liquid phase wets every tungsten grain.

- If your primary focus is microstructural uniformity: Focus on precise temperature regulation to control the melting of the binder elements (Fe, Ni, Co) and prevent grain agglomeration.

Success in sintering Tungsten Pseudo-alloys relies on balancing thermal energy with atmospheric purity to achieve a perfectly wetted, dense structure.

Summary Table:

| Core Function | Description | Impact on Result |

|---|---|---|

| Liquid Phase Creation | Melts binder elements (Ni, Fe, Co) while tungsten remains solid. | Creates the matrix for consolidation. |

| Surface Purification | Vacuum removes oxides and adsorbed gases from particles. | Ensures perfect wetting of tungsten grains. |

| Capillary Densification | Driven by wetting action after oxide removal. | Achieves high structural density and uniformity. |

| Thermal Regulation | Precise control of melting points and hold times. | Prevents component distortion and grain growth. |

Elevate Your Materials Research with KINTEK Precision

Are you struggling with structural defects or inconsistent density in your tungsten pseudo-alloys? Success in liquid phase sintering requires the perfect balance of atmospheric purity and thermal control. KINTEK provides industry-leading, customizable Vacuum, Muffle, Tube, and CVD systems designed to meet the rigorous demands of advanced metallurgy.

Backed by expert R&D and world-class manufacturing, our high-temperature furnaces ensure complete oxide removal and precise binder melting for superior results. Contact us today to find the perfect sintering solution for your lab!

Visual Guide

References

- Adéla Macháčková, Silvie Brožová. Applications of Tungsten Pseudo-Alloys in the Energy Sector. DOI: 10.3390/app14020647

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does vacuum brazing work? Achieve Superior Joint Integrity for Critical Applications

- What advantages does a vacuum drying oven offer? Preserve Activated Carbon Structure and Adsorption Capacity

- What is 'hydrogen disease' in copper heat treatment and how does vacuum annealing prevent it? Learn to Avoid Catastrophic Failure

- What infrared materials can be produced using high temperature vacuum furnaces? Discover ZnS, ZnSe, and More

- What factors should be considered when choosing a vacuum furnace model? Key Insights for Optimal Performance

- What components make up the vacuum system of a vacuum furnace? Unlock Precision for High-Temperature Processing

- What factors are crucial for successful vacuum brazing? Master Cleanliness, Joint Design, and Thermal Control

- How do the drying conditions in a vacuum drying oven affect NiS2 electrode quality? Optimize Your Battery Performance