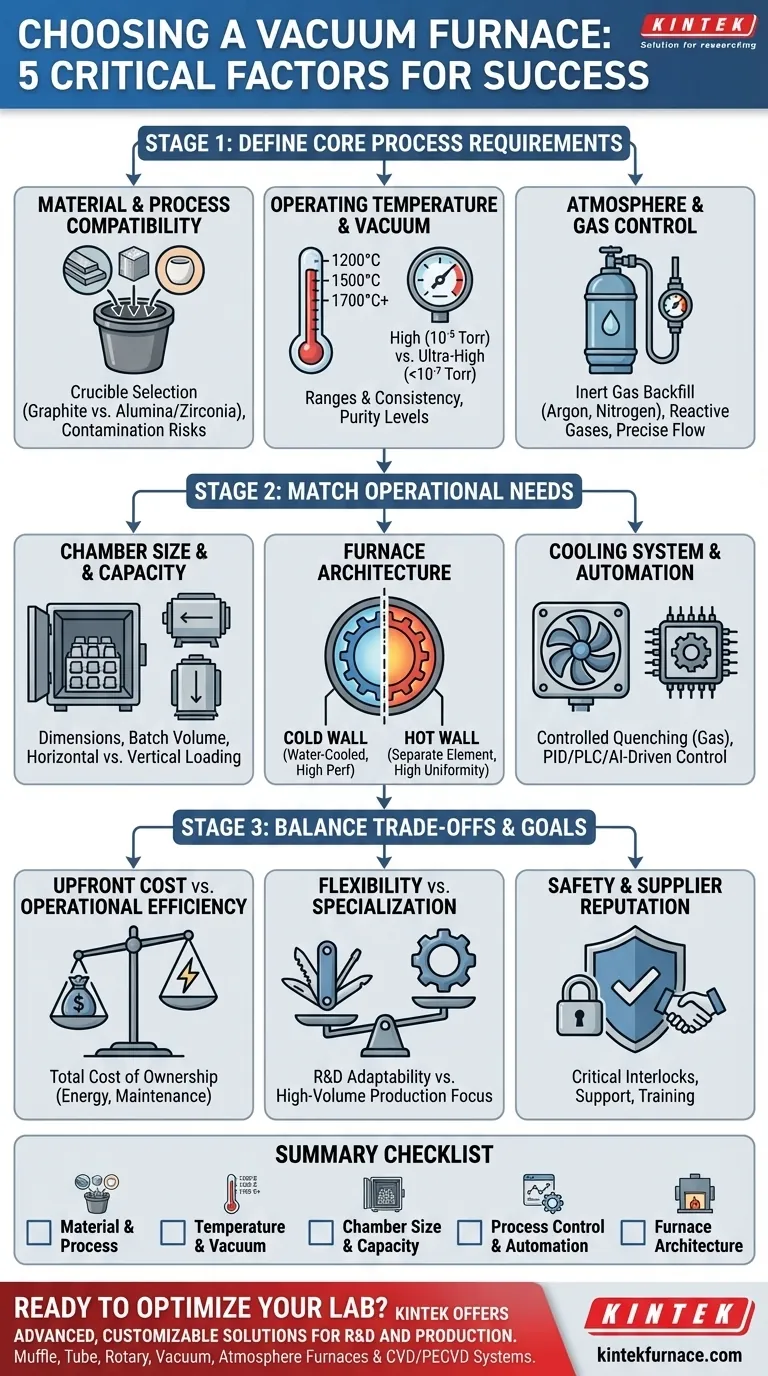

At its core, choosing a vacuum furnace requires a systematic evaluation of five critical factors: the material and process requirements, the necessary operating temperature, the required vacuum level, the physical size and capacity, and the level of process control and automation you need. Matching these factors to your specific application is the only way to ensure a successful and cost-effective investment.

The most common mistake is focusing on a single specification, like maximum temperature or chamber size. The right vacuum furnace is not the one with the best individual metrics, but the one whose entire system—from heating elements and vacuum pumps to controls and cooling—is holistically designed for your specific material and process goal.

Defining Your Core Process Requirements

Before evaluating any furnace model, you must first define the metallurgical or chemical process you need to perform. The material's properties and the desired outcome dictate every subsequent equipment specification.

Material Compatibility and Process Type

The specific material you are processing is the starting point. Its characteristics determine the type of heating, the potential for contamination, and the required environment.

For example, processing reactive metals like titanium requires a very different furnace environment than sintering steel parts. This also dictates crucible selection—using a graphite crucible with certain alloys could introduce unwanted carbides, making inert materials like alumina or zirconia a better choice.

Maximum Operating Temperature

The furnace must be able to consistently reach and hold the temperature your process requires. Manufacturers often categorize furnaces by their peak temperatures, with common ranges being 1200°C, 1500°C, and 1700°C.

Choosing a furnace with a significantly higher temperature range than you need often leads to unnecessary expense and potential inefficiencies. Conversely, under-specifying temperature will make your process impossible.

Required Vacuum Level

The "vacuum" in a vacuum furnace is not a single state; it exists on a spectrum. The level of vacuum required is determined by the need to prevent unwanted chemical reactions, such as oxidation, or to remove dissolved impurities from the material.

A high vacuum (around 10⁻⁵ to 10⁻⁷ Torr) is sufficient for many heat treatment processes. However, applications requiring extreme purity, such as those involving highly reactive metals, may demand an ultra-high vacuum (below 10⁻⁷ Torr) to minimize residual gas contamination.

Atmosphere and Gas Control

Many advanced processes require more than just a vacuum. The ability to backfill the chamber with a precise mixture of high-purity inert gas (like Argon or Nitrogen) is critical for controlled cooling or for providing a specific pressure environment.

Some applications may even use reactive gases to achieve a desired surface chemistry. A furnace's gas control system, including its mass flow controllers and plumbing, must be designed for the specific gases and pressures your process demands.

Matching the Furnace to Your Operational Needs

Once the core process parameters are set, you must consider how the furnace will fit into your facility and workflow. These factors relate to production rate, efficiency, and repeatability.

Chamber Size and Load Capacity

The furnace's internal chamber size must accommodate your parts and batch sizes. Consider both the dimensions of a single large part and the total volume needed for a batch of smaller parts.

This also influences the furnace orientation. Horizontal loading is common and often easier for manual or forklift loading. Vertical loading can be advantageous for preventing distortion in long, slender parts or for specific automated production lines.

Furnace Architecture: Hot Wall vs. Cold Wall

This is a fundamental design difference with significant implications.

Cold wall furnaces are the most common type for high-performance applications. The heating elements are inside the vacuum chamber, which is surrounded by a water-cooled jacket. This design allows for very high temperatures, rapid heating and cooling cycles, and excellent temperature uniformity.

Hot wall furnaces place the vacuum chamber (often a ceramic or quartz tube) inside a separate, larger heating element array. They are typically limited to lower temperatures but can be ideal for specific, highly uniform processes where slower cycling is acceptable.

The Cooling System's Role

Cooling is not an afterthought; it is a critical, controlled part of the process that determines the final microstructure and mechanical properties of the material.

The efficiency and method of the cooling system (e.g., inert gas quenching, fan speed control) dictate how quickly you can solidify or cool a part. A system that provides slow, inconsistent cooling can ruin the results of a perfectly executed heating cycle.

Automation and Process Control

The control system is the brain of the furnace, ensuring your process is repeatable and accurate. The level of sophistication should match your quality assurance and operational needs.

- PID Controllers: Provide basic, reliable temperature control for simpler processes.

- PLC Systems: Offer programmable logic control for managing complex cycles with multiple steps, gas flows, and vacuum setpoints. This is the standard for most industrial applications. -- AI-Driven Automation: Advanced systems can use data to optimize cycles for energy efficiency and predict maintenance needs, ensuring maximum uptime and quality.

Understanding the Trade-offs

No furnace is perfect for every task. Being aware of the inherent compromises is key to making a wise long-term decision.

Upfront Cost vs. Operational Efficiency

A lower initial purchase price can be tempting, but it may hide higher long-term costs. A less efficient furnace will consume more energy, require more frequent maintenance, and use more consumable materials.

Always evaluate the total cost of ownership, factoring in energy consumption, cycle time, and expected maintenance. Modern furnaces with better insulation and more efficient power supplies often provide significant energy savings.

Flexibility vs. Specialization

A highly customized furnace built for a single process will likely perform that one task with exceptional efficiency. However, it may be completely unsuited for future R&D or a new product line.

A more general-purpose furnace might offer a wider temperature range and more flexible gas options, providing more value over the long term if your process needs are likely to evolve.

Safety and Supplier Reputation

Vacuum furnaces operate at extreme temperatures and pressures, making safety paramount. Ensure any model includes critical safety interlocks, such as automatic power shut-off when the door is opened, and over-temperature protection.

Finally, consider the manufacturer's reputation. A reliable supplier provides more than just a machine; they offer expert installation, training, and responsive service, which is invaluable for complex equipment.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary objective.

- If your primary focus is R&D and material science: Prioritize a flexible furnace with precise process control, a wide operating window (temperature and vacuum), and robust data-logging capabilities.

- If your primary focus is high-volume production: Emphasize automation, fast cycle times (heating and cooling), energy efficiency, and chamber capacity to maximize throughput and minimize cost per part.

- If your primary focus is processing highly reactive or pure materials: Concentrate on achieving ultra-high vacuum levels, ensuring material compatibility of all internal components (like crucibles), and precise atmosphere control.

Ultimately, selecting the right vacuum furnace is a process of translating your specific material goals into a detailed equipment specification.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material & Process | Compatibility, contamination risks, crucible selection |

| Operating Temperature | Ranges (e.g., 1200°C, 1500°C, 1700°C), consistency |

| Vacuum Level | High vacuum (10⁻⁵ to 10⁻⁷ Torr) vs. ultra-high vacuum (<10⁻⁷ Torr) |

| Chamber Size & Capacity | Dimensions, batch volume, horizontal/vertical loading |

| Process Control & Automation | PID controllers, PLC systems, AI-driven options |

| Cooling System | Efficiency, gas quenching, impact on material properties |

| Furnace Architecture | Cold wall (high performance) vs. hot wall (uniformity) |

| Cost & Flexibility | Upfront cost vs. total ownership, specialization vs. adaptability |

Ready to optimize your lab with the perfect vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in R&D, high-volume production, or processing reactive materials, we ensure superior performance, efficiency, and safety. Contact us today to discuss how we can enhance your processes and deliver reliable results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance