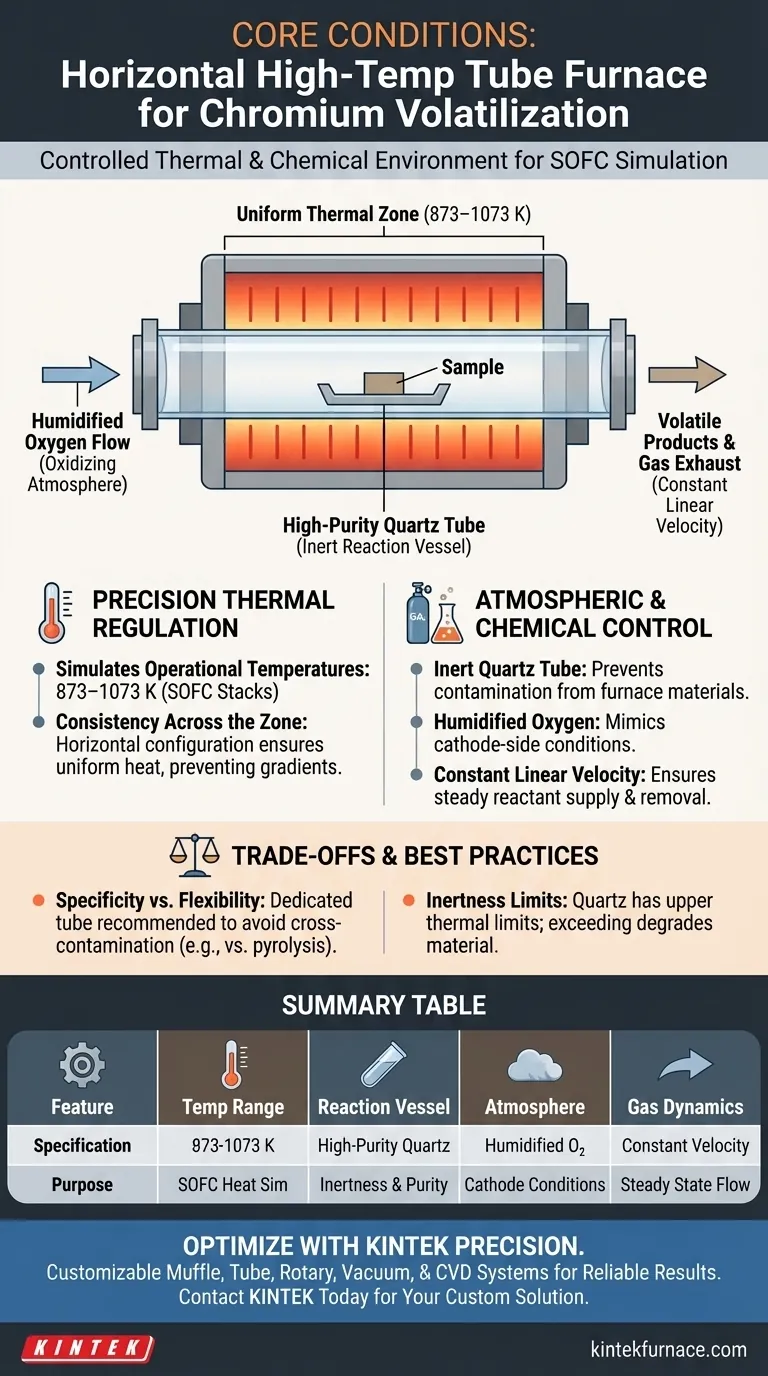

A horizontal high-temperature tube furnace provides a controlled thermal and chemical environment specifically designed to isolate and measure the volatilization of chromium. Ideally suited for simulating Solid Oxide Fuel Cell (SOFC) operations, the system maintains a precise temperature range between 873 and 1073 K while directing a constant flow of humidified oxygen over the sample through a chemically inert vessel.

The core value of this experimental setup lies in its ability to simulate realistic operating conditions while eliminating external variables. By utilizing an inert quartz channel and regulated gas flow, it ensures that any measured volatilization is purely a result of the sample’s interaction with the thermal and chemical environment.

Precision Thermal Regulation

Simulating Operational Temperatures

To accurately measure chromium volatilization, the furnace must replicate the intense heat found in real-world applications like SOFC stacks.

The core requirement is a stable heating environment capable of sustaining temperatures between 873 and 1073 K.

Consistency Across the Zone

The horizontal configuration of the furnace is critical for maintaining a uniform thermal zone.

This ensures the entire sample surface is exposed to the exact same temperature, preventing thermal gradients that could skew volatilization data.

Atmospheric and Chemical Control

The Role of the High-Purity Quartz Tube

The "core" of the experiment is the internal reaction vessel, which is a high-purity quartz tube.

This component acts as a chemically inert gas channel. Its neutrality is vital because it prevents the furnace materials themselves from reacting with the sample or the gas, which would contaminate the results.

Controlled Gas Composition

Unlike pyrolysis experiments that require oxygen-free environments, measuring chromium volatilization specifically requires an oxidizing atmosphere.

The system facilitates the flow of humidified oxygen over the sample. This specific combination is necessary to mimic the cathode-side conditions of a fuel cell, where chromium volatility is most problematic.

Constant Linear Velocity

Precision in gas flow is just as important as the gas composition.

The furnace setup ensures the gas moves at a constant linear velocity. This guarantees that the rate of reactant supply and product removal remains steady throughout the experiment, enabling quantitative capture of volatile products.

Understanding the Trade-offs

Specificity vs. Flexibility

While tube furnaces are versatile tools—capable of performing anoxic pyrolysis at lower temperatures (400–550°C) for other applications—this specific setup is tuned for high-temperature oxidation.

Using the same tube for different types of experiments (e.g., switching between chromium volatilization and biomass pyrolysis) carries a high risk of cross-contamination.

Inertness Limitations

While high-purity quartz is excellent for the 873–1073 K range, it has upper thermal limits.

Pushing the furnace significantly beyond this range to test extreme scenarios may degrade the quartz, introducing impurities into the gas stream and compromising the data.

Making the Right Choice for Your Goal

To ensure your data is valid and applicable to your specific engineering challenge, prioritize the following parameters:

- If your primary focus is SOFC Simulation: Strictly maintain the temperature window of 873–1073 K and ensure the oxygen stream is humidified to match operational reality.

- If your primary focus is Data Purity: Invest in a dedicated high-purity quartz tube used solely for chromium testing to avoid trace contamination from previous, unrelated experiments.

Success in measuring volatilization relies not just on heating the sample, but on creating a strictly defined flow environment that isolates the reaction of interest.

Summary Table:

| Feature | Specification/Requirement | Purpose in Experiment |

|---|---|---|

| Temperature Range | 873 - 1073 K | Simulates real-world SOFC operating heat |

| Reaction Vessel | High-Purity Quartz Tube | Ensures chemical inertness and zero contamination |

| Atmosphere | Humidified Oxygen | Replicates cathode-side oxidizing conditions |

| Gas Dynamics | Constant Linear Velocity | Guarantees steady reactant supply and product removal |

| Configuration | Horizontal Tube | Maintains a uniform thermal zone across the sample |

Optimize Your Materials Testing with KINTEK Precision

Precise control over thermal and chemical environments is critical for accurate chromium volatilization data. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your laboratory's unique high-temperature needs.

Whether you are simulating SOFC environments or conducting complex material synthesis, our lab furnaces deliver the uniformity and reliability your research demands. Don't leave your data to chance.

Contact KINTEK Today to Design Your Custom Furnace Solution

Visual Guide

References

- Thammaporn Thublaor, Somrerk Chandra-ambhorn. Novel Method for Determining Standard Enthalpy and Entropy of Volatilisation of Chromia Exposed to Humidified Oxygen at 298 K Based on Transport Theory of Multicomponent Gas Mixtures. DOI: 10.3390/e27020101

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How are tubular furnaces used in chemical synthesis? Unlock Precise Material Creation

- What is the function of secondary calcination in a tube furnace? Enhance Cu@Zn-NC Adsorbent Longevity

- What industries commonly use tube furnaces? Essential for High-Tech Materials and Electronics

- What are the specifications for large volume single zone tube furnaces? Find Your Ideal High-Temp Solution

- Is it safe to use a quartz tube furnace at high temperatures? Ensure Safety with the Right Tube Material

- What is the primary role of a tube furnace in the evaluation of cable material smoke acidity? Achieve Precise Testing

- What is the primary function of a tube furnace for REBCO tapes? Find Critical 175°C Thresholds

- What is the function of vacuum-sealed tubes and controlled heating? Master Ruthenium Precursor Embedding