In short, large volume single-zone tube furnaces are defined by their operating temperature and physical capacity. For example, a common configuration offers a 6-inch diameter by 14-inch heated length, with models available for maximum temperatures of 1400°C (compatible with metallic or ceramic tubes) and 1700°C (requiring ceramic tubes).

The specific temperature and dimension specifications are only the starting point. The crucial decision lies in matching these core specs with the required process tube material, atmosphere control, and automation level to ensure your furnace meets the precise demands of your application.

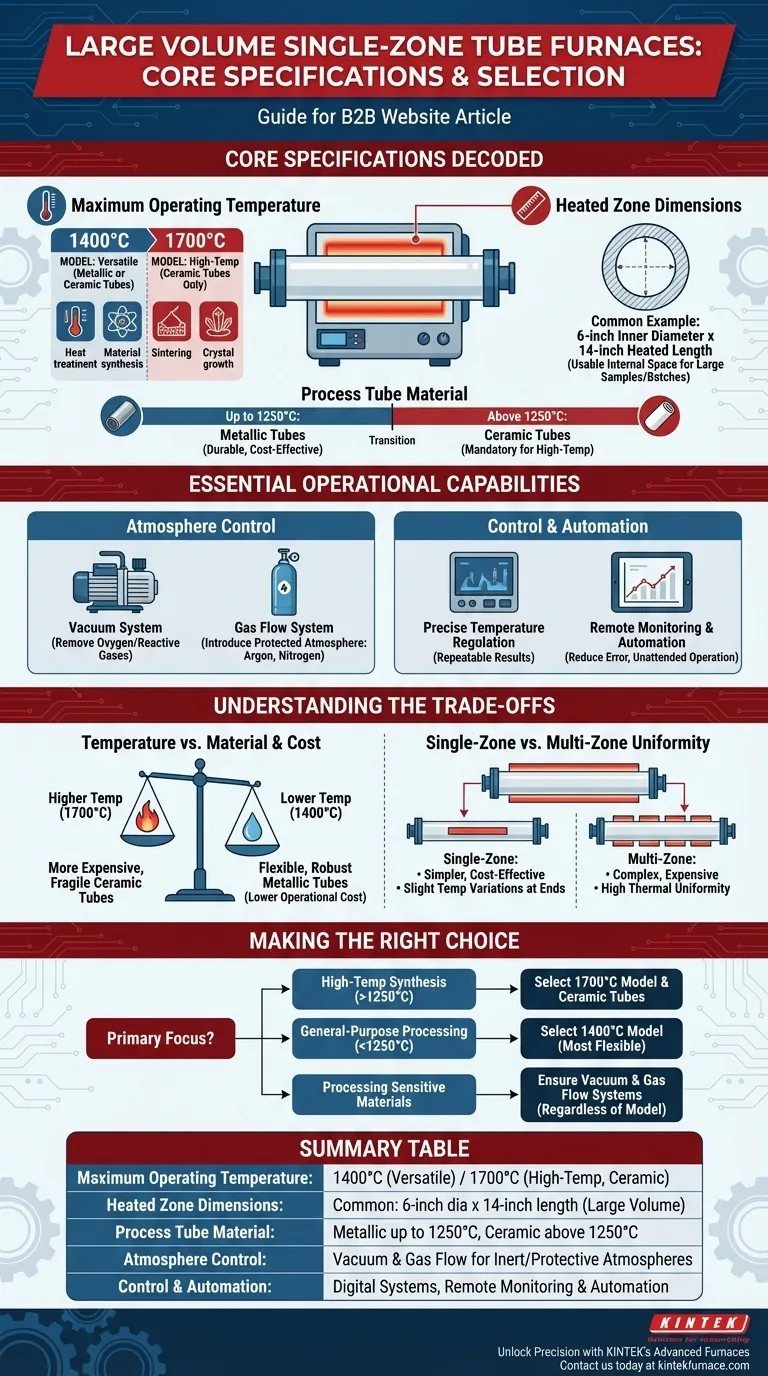

Core Specifications Decoded

Understanding the primary specifications is the first step in selecting the correct furnace. Each parameter directly influences the types of processes you can run.

Maximum Operating Temperature

The maximum temperature is the single most important specification. Models are typically distinguished by this rating.

A 1400°C furnace offers versatility for a wide range of general-purpose heat treatment and material synthesis applications.

A 1700°C furnace is designed for high-temperature processes, such as sintering advanced ceramics or growing specific crystals, which are unattainable at lower temperatures.

Heated Zone Dimensions

The term "large volume" refers to the usable internal space. A common example is a 6-inch inner diameter by 14-inch heated length.

This volume determines the maximum size of your sample or the batch throughput you can achieve in a single run.

Process Tube Material

The process tube contains your sample and atmosphere, and its material is dictated by your operating temperature.

For temperatures up to 1250°C, durable and cost-effective metallic tubes are often suitable.

For temperatures above 1250°C, a ceramic tube (like alumina) is mandatory, as metals would soften and fail. All 1700°C operations require ceramic tubes.

Essential Operational Capabilities

Beyond the basic specifications, key features enable precise and repeatable results. These capabilities transform the furnace from a simple heater into a sophisticated processing tool.

Atmosphere Control

Many advanced material processes cannot be performed in ambient air. Furnaces can be equipped with systems for atmosphere control.

This includes a vacuum system to remove oxygen and other reactive gases, and a gas flow system to introduce a specific, protected atmosphere like argon or nitrogen. This is critical for preventing oxidation and enabling specific chemical reactions.

Control and Automation

Modern furnaces feature intelligent digital control systems. This is no longer a luxury but a core feature for process reliability.

Precise temperature regulation ensures that your process follows a specific heating and cooling profile, which is essential for repeatable results.

Remote monitoring and automation reduce the chance of human error, allow for unattended operation, and enable continuous, documented production cycles.

Understanding the Trade-offs

Choosing a furnace involves balancing performance, flexibility, and cost. Recognizing these trade-offs is key to making an informed decision.

Temperature vs. Material and Cost

The desire for higher temperatures comes with a direct trade-off. While a 1700°C furnace offers greater process capabilities, it locks you into using more expensive and potentially fragile ceramic process tubes.

A 1400°C furnace provides more flexibility, allowing the use of robust metallic tubes for lower-temperature work, which can reduce operational costs and simplify handling.

Single-Zone vs. Multi-Zone Uniformity

The models described are single-zone furnaces. This means one set of heating elements and one controller are responsible for the entire heated length.

While simpler and more cost-effective, a single zone may have slight temperature variations toward the ends of the tube. For applications requiring exceptionally high thermal uniformity across a long sample, a more complex multi-zone furnace would be necessary.

Making the Right Choice for Your Application

To select the right furnace, align the specifications directly with your primary research or production goal.

- If your primary focus is high-temperature synthesis (>1250°C): Your choice must be a high-temperature model (e.g., 1700°C) and you must budget for the mandatory ceramic process tubes.

- If your primary focus is general-purpose processing (<1250°C): A 1400°C model offers the most flexibility, allowing you to use durable metallic tubes for most work while retaining the option to use ceramic tubes for higher temperatures.

- If your primary focus is processing sensitive materials: Regardless of the temperature model, ensure you specify the furnace with the necessary vacuum and gas flow systems to control the process atmosphere.

By clearly defining your operational needs first, you can confidently select a furnace with the specifications to achieve your goals.

Summary Table:

| Specification | Details |

|---|---|

| Maximum Operating Temperature | 1400°C (versatile, metallic/ceramic tubes) or 1700°C (high-temp, ceramic tubes) |

| Heated Zone Dimensions | Common: 6-inch diameter by 14-inch length (large volume for samples/batches) |

| Process Tube Material | Metallic tubes up to 1250°C, ceramic tubes above 1250°C |

| Atmosphere Control | Vacuum and gas flow systems for inert/protective atmospheres |

| Control and Automation | Digital systems for precise temperature, remote monitoring, and automation |

Unlock Precision in Your Lab with KINTEK's Advanced Tube Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs—whether for high-temperature synthesis, general processing, or sensitive material handling.

Contact us today to discuss how our furnaces can enhance your efficiency and achieve reliable results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability