From semiconductor fabrication to advanced materials research, tube furnaces are essential tools across a diverse range of high-tech and industrial sectors. They are fixtures in metallurgy, battery development, electronics manufacturing, and chemical processing due to their ability to create highly controlled, high-temperature environments for processing materials.

A tube furnace's value isn't defined by the industry it serves, but by the process it enables. Its core function is to provide an extremely precise, controllable thermal environment—often with a specific atmosphere—which is a fundamental requirement for creating the advanced materials and components that drive modern technology.

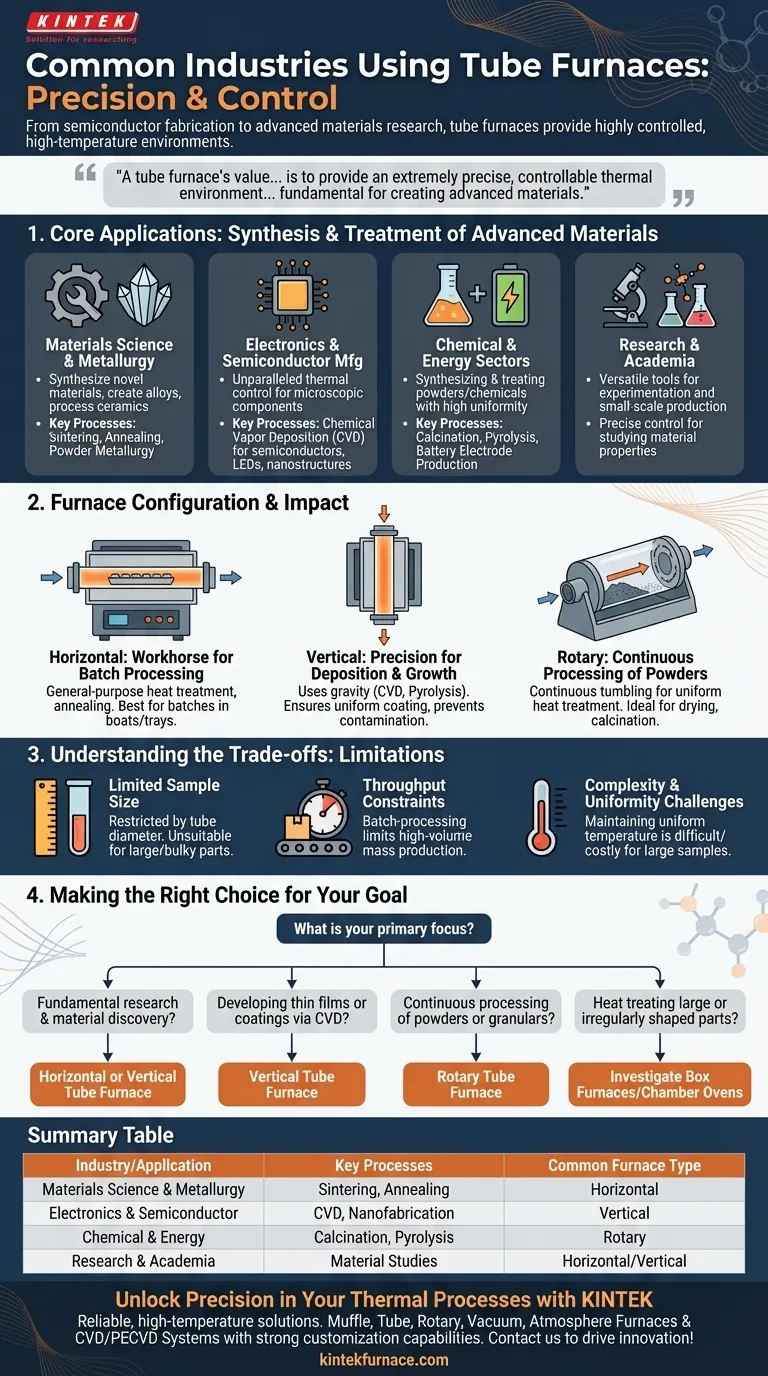

Core Applications: The Synthesis and Treatment of Advanced Materials

The primary use of tube furnaces revolves around the thermal processing of materials where precision is non-negotiable. They are not used for bulk heating but for transformative processes that define a material's final properties.

Materials Science & Metallurgy

This is the most common application area. Tube furnaces are used to synthesize novel materials, create alloys, and process high-performance ceramics.

Key processes include sintering (fusing powders into a solid mass), annealing (altering a material's microstructure to improve ductility), and powder metallurgy.

Electronics & Semiconductor Manufacturing

The electronics industry relies on tube furnaces for their unparalleled thermal control, which is critical for fabricating microscopic components.

They are fundamental for processes like Chemical Vapor Deposition (CVD), where gases react to form a solid thin film on a substrate. This is used to create semiconductors, nanostructures, and components for devices like LEDs.

Chemical & Energy Sectors

In the chemical industry, tube furnaces are used for synthesizing and treating powders and chemicals with high uniformity. This includes calcination (heating to high temperatures in the absence of air) and pyrolysis (thermal decomposition).

These processes are vital in developing materials for the energy sector, such as creating the positive and negative electrode materials used in lithium-ion batteries.

Research & Academia

University labs, research institutes, and corporate R&D departments use tube furnaces as versatile tools for experimentation and small-scale production.

Their ability to precisely control temperature, pressure, and atmosphere makes them ideal for studying material properties and developing the next generation of materials.

Furnace Configuration and Its Impact on Application

The physical orientation of the furnace tube—horizontal, vertical, or rotary—is not an arbitrary design choice. Each configuration is optimized for specific industrial processes.

Horizontal Furnaces: The Workhorse for Batch Processing

Horizontal furnaces are the most common type, frequently used for general-purpose heat treatment, annealing, and thermal analysis of samples.

They are well-suited for processing material batches placed in boats or trays, offering a straightforward and reliable method for many standard laboratory and industrial tasks.

Vertical Furnaces: Precision for Deposition and Growth

Vertical furnaces are preferred for processes where gravity can be used to an advantage, such as CVD, pyrolysis, and the thermal decomposition of materials.

This orientation helps ensure a uniform coating on substrates and can prevent sample contamination or deformation that might occur in a horizontal setup, making it crucial for high-purity electronics applications.

Rotary Furnaces: Continuous Processing of Powders

Rotary tube furnaces are designed for the continuous processing of powders and granular materials. The tube rotates slowly, tumbling the material to ensure every particle receives uniform heat treatment.

This design is ideal for industrial applications like drying, calcination, and solid waste incineration, where high throughput and consistency are critical.

Understanding the Trade-offs

While powerful, a tube furnace is a specialized tool and is not the right solution for every thermal processing need. Understanding its limitations is key to making a sound investment.

Limited Sample Size

The defining feature of a tube furnace—the tube—is also its primary limitation. The diameter of the tube inherently restricts the size and shape of the object you can process.

They are unsuitable for heat-treating large, bulky, or irregularly shaped components. For those tasks, a box furnace or chamber oven is a more appropriate choice.

Throughput Constraints

Most standard horizontal and vertical tube furnaces are batch-processing systems. This means they can only process a finite amount of material at a time, making them less suitable for high-volume mass production lines compared to continuous systems like conveyor furnaces.

Complexity and Uniformity Challenges

Maintaining a perfectly uniform temperature zone across the entire length of the tube becomes increasingly difficult and expensive as the tube diameter and length grow. For very large samples, achieving the required uniformity may be impractical or cost-prohibitive.

Making the Right Choice for Your Goal

Your selection of a thermal processing tool should be driven entirely by the specific requirements of your material and process.

- If your primary focus is fundamental research and material discovery: A versatile horizontal or vertical tube furnace offers the precise control needed for experimental work.

- If your primary focus is developing thin films or coatings via CVD: A vertical tube furnace is the industry standard for achieving the necessary uniform deposition.

- If your primary focus is continuous processing of powders or granulars: A rotary tube furnace is specifically designed for this high-throughput application.

- If your primary focus is heat treating large or irregularly shaped parts: You should investigate box furnaces or chamber ovens, as a tube furnace is likely too restrictive.

Ultimately, choosing the right furnace begins with a clear understanding of your material, your process, and your desired outcome.

Summary Table:

| Industry/Application | Key Processes | Common Furnace Type |

|---|---|---|

| Materials Science & Metallurgy | Sintering, Annealing, Powder Metallurgy | Horizontal |

| Electronics & Semiconductor | Chemical Vapor Deposition (CVD), Nanostructure Fabrication | Vertical |

| Chemical & Energy | Calcination, Pyrolysis, Battery Electrode Production | Rotary |

| Research & Academia | Material Property Studies, Small-Scale Synthesis | Horizontal/Vertical |

Unlock Precision in Your Thermal Processes with KINTEK

Are you working in materials science, electronics, or energy sectors and need reliable, high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced tube furnaces tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your experimental requirements.

Contact us today to discuss how our furnaces can enhance your efficiency and drive innovation in your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis