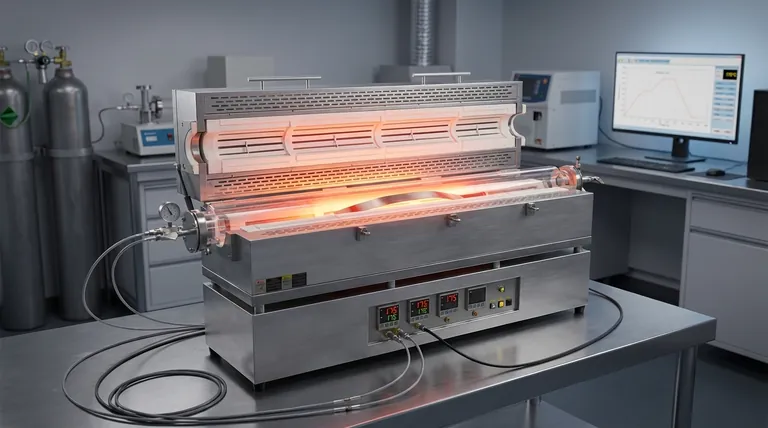

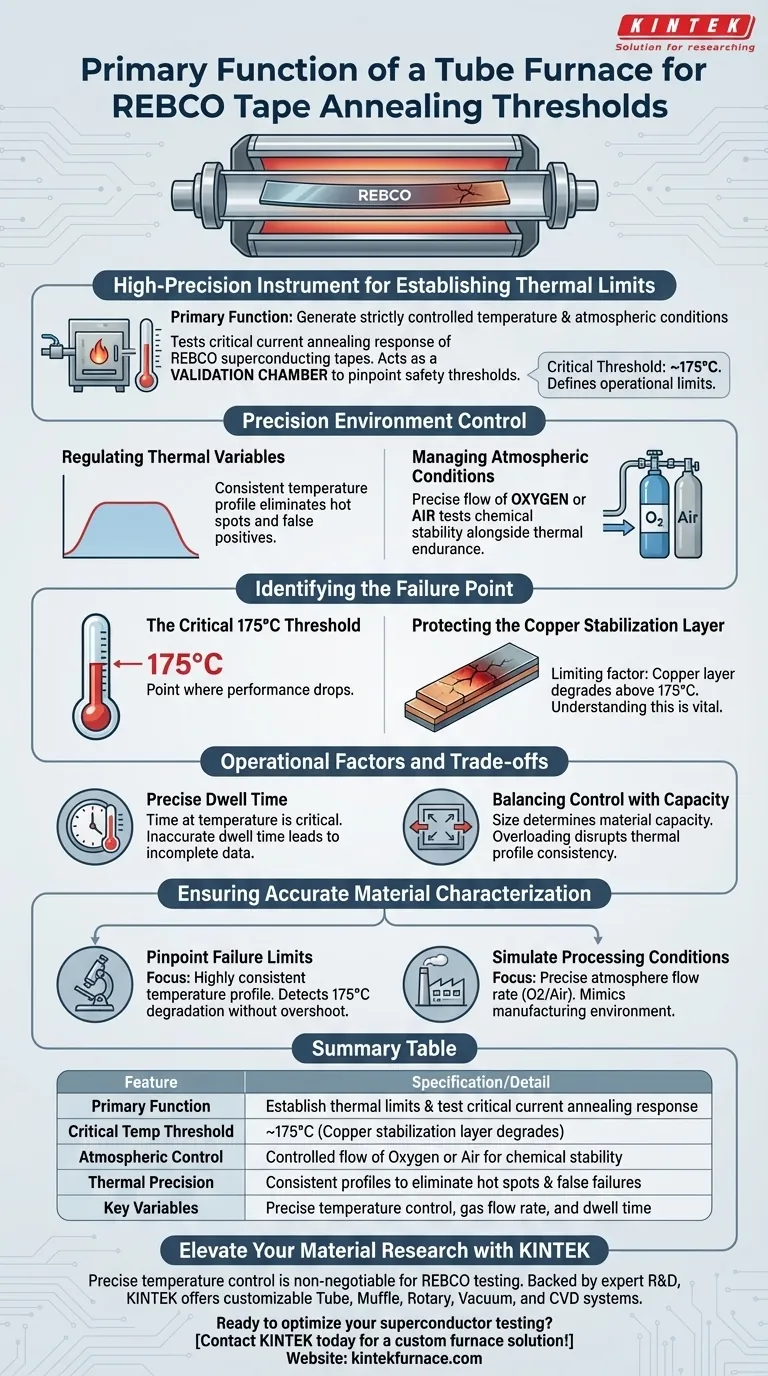

A tube furnace serves as a high-precision instrument for establishing thermal limits. Its primary function is to generate a strictly controlled temperature environment and specific atmospheric conditions—typically oxygen or air—to rigorously test the critical current annealing response of REBCO superconducting tapes.

The tube furnace acts as a validation chamber, enabling researchers to pinpoint the critical safety threshold—approximately 175°C—where the copper stabilization layer begins to degrade, thereby defining the operational limits of the superconductor.

Precision Environment Control

Regulating Thermal Variables

To determine an accurate annealing threshold, the testing environment must be free of fluctuations. A tube furnace provides the necessary consistent temperature profile, ensuring that the REBCO tape is heated uniformly.

This uniformity eliminates hot spots that could lead to false positives regarding material failure.

Managing Atmospheric Conditions

Beyond heat, the chemical environment is critical. The furnace allows for the precise flow of specific gases, such as oxygen or air, during the heating process.

This controlled atmosphere ensures that the chemical stability of the tape is tested alongside its thermal endurance, replicating real-world processing or operating conditions.

Identifying the Failure Point

The Critical 175°C Threshold

The ultimate goal of using the furnace in this context is to identify the exact temperature where performance drops.

For REBCO tapes, this critical threshold is identified at approximately 175 degrees Celsius.

Protecting the Copper Stabilization Layer

The limiting factor in these tapes is often not the superconductor itself, but the surrounding architecture.

The tube furnace tests reveal that above the 175°C mark, the copper stabilization layer suffers degradation. Understanding this limit is vital for preventing structural failure in practical applications.

Operational Factors and Trade-offs

The Necessity of Precise Dwell Time

Temperature is not the only variable; time matters. As noted in broader furnace applications, the dwell time—how long the material remains at a specific temperature—is a critical factor.

If the tape is not held at the target temperature for the correct duration, the data regarding the annealing threshold may be incomplete or inaccurate.

Balancing Control with Capacity

While a tube furnace offers superior control, operators must consider the physical constraints of the workspace.

The size of the workspace determines how much material can be tested simultaneously without compromising the consistency of the thermal profile. Overloading the furnace can disrupt the airflow and heat distribution, invalidating the test results.

Ensuring Accurate Material Characterization

To obtain reliable data on REBCO tape performance, you must align your furnace settings with your specific testing goals.

- If your primary focus is pinpointing failure limits: Ensure your furnace creates a highly consistent temperature profile to accurately detect the 175°C degradation point without thermal overshoot.

- If your primary focus is simulating processing conditions: Prioritize precise control over the atmosphere flow rate (oxygen or air) to mimic the exact environment the tape will face during manufacturing.

By rigorously controlling both temperature and atmosphere, you transform the tube furnace from a simple heater into a critical tool for verifying superconductor reliability.

Summary Table:

| Feature | Specification/Detail |

|---|---|

| Primary Function | Establish thermal limits & test critical current annealing response |

| Critical Temperature Threshold | ~175°C (Point where copper stabilization layer degrades) |

| Atmospheric Control | Controlled flow of Oxygen or Air for chemical stability |

| Thermal Precision | Consistent profiles to eliminate hot spots and false failures |

| Key Variables | Precise temperature control, gas flow rate, and dwell time |

Elevate Your Material Research with KINTEK

Precise temperature control is non-negotiable when determining the critical thresholds of REBCO superconducting tapes. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory requirements.

Whether you need to simulate complex processing atmospheres or maintain rigorous thermal profiles at 175°C and beyond, our engineering team is ready to help you achieve accurate, repeatable results.

Ready to optimize your superconductor testing? Contact KINTEK today for a custom furnace solution!

Visual Guide

References

- Zili Zhang, Qiuliang Wang. A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint. DOI: 10.3390/ma18133053

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What types of atmospheres can a horizontal electric furnace control? Master Material Processing with Precision

- How does a tube furnace facilitate the transformation of natural wood into a Carbonized Wood carrier? Master Pyrolysis

- What safety precautions should be taken when using a High Temperature Tube Furnace? Essential Tips for Safe Operation

- What are the benefits of continuous movement of the sample in a rotary tube furnace? Achieve Superior Uniformity and Efficiency

- What are the features of multi-zone tube furnaces? Unlock Precision Heating for Your Lab

- What are the core advantages of using a Drop Tube Furnace compared to a TGA? Bridge Lab Theory and Industrial Reality

- How does a tube furnace contribute to the ammonia reduction annealing process for (NiZnMg)MoN catalysts? Optimize Phase Transitions

- What makes fluidized bed vertical tube furnaces environmentally friendly? Discover Efficient Green Tech Solutions