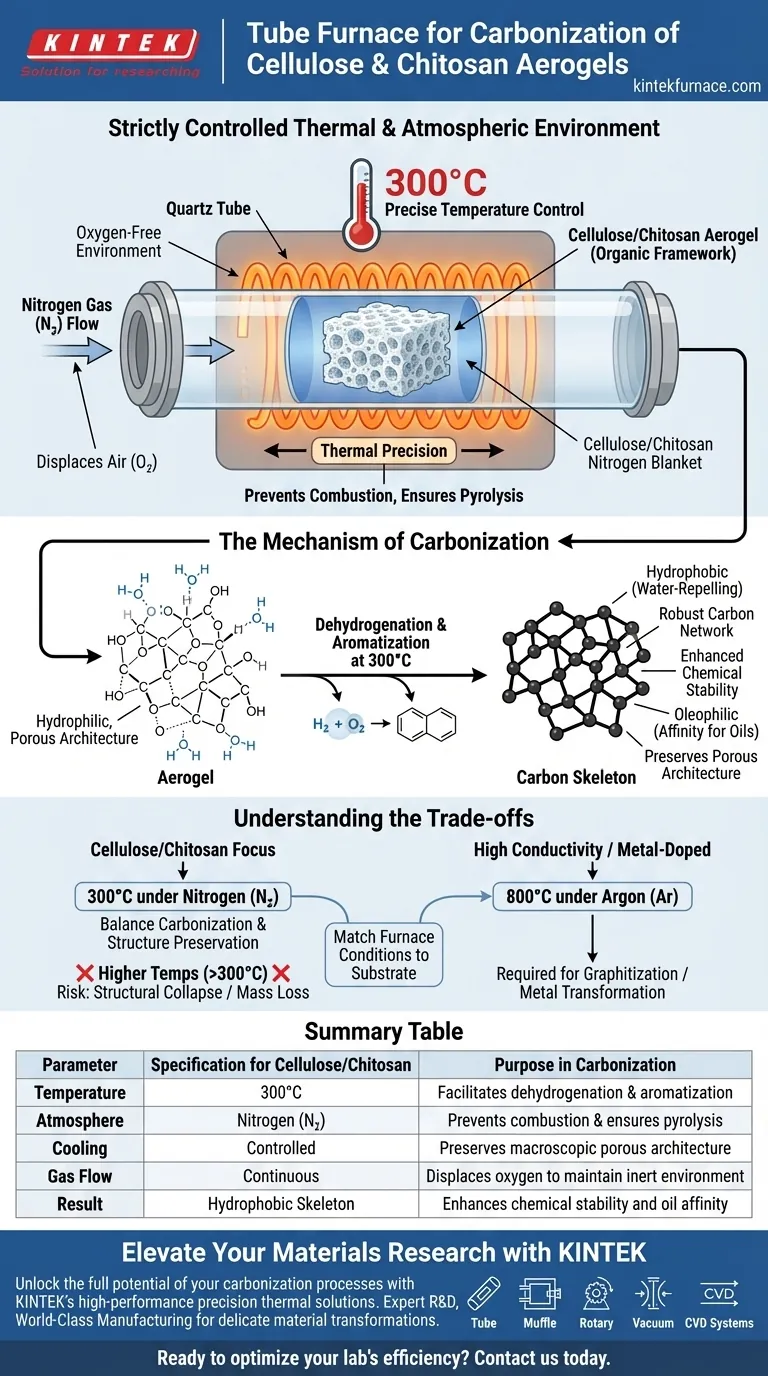

A tube furnace establishes a strictly controlled thermal and atmospheric environment critical for material transformation. For the carbonization of cellulose and chitosan aerogels specifically, it provides precise temperature control at 300°C and a stable nitrogen protection atmosphere.

The tube furnace functions as a specialized reaction chamber that prevents oxidation, allowing the organic aerogel framework to chemically restructure into a hydrophobic carbon skeleton without collapsing its porous architecture.

Creating the Critical Environment

Nitrogen Protection Atmosphere

The primary function of the tube furnace in this process is to establish an oxygen-free environment. By maintaining a continuous flow of nitrogen gas, the furnace displaces atmospheric air that would otherwise cause the organic aerogel to burn (oxidize) rather than carbonize.

Prevention of Combustion

Without this inert nitrogen blanket, the high temperatures required for processing would destroy the material. The strict atmospheric control ensures the aerogel undergoes pyrolysis (thermal decomposition in the absence of oxygen) rather than combustion.

The Mechanism of Carbonization

Thermal Precision at 300°C

Unlike harder materials that may require temperatures upwards of 800°C, cellulose and chitosan aerogels are processed at a controlled 300°C. The tube furnace maintains this specific heat profile to drive chemical changes without obliterating the delicate aerogel structure.

Dehydrogenation and Aromatization

At this temperature, the heat facilitates dehydrogenation and aromatization reactions. This process removes hydrogen atoms and forms stable aromatic ring structures, effectively converting the biological organic framework into a robust carbon network.

Achieving Hydrophobicity

This chemical restructuring fundamentally alters the material's properties. It transforms the naturally hydrophilic (water-absorbing) cellulose and chitosan into a hydrophobic (water-repelling) carbon skeleton, significantly enhancing its chemical stability and oleophilicity (affinity for oils).

Understanding the Trade-offs

Temperature Specificity vs. Material Limits

While tube furnaces can reach much higher temperatures (e.g., 800°C for metal-doped aerogels), applying excessive heat to cellulose/chitosan can be detrimental. You must adhere to the 300°C guideline to preserve the macroscopic porous structure; higher temperatures risk structural collapse or excessive mass loss.

Gas Selection and Cost

For cellulose and chitosan, nitrogen is the standard protective gas. While other processes utilize argon (Ar) for extremely sensitive materials (like conductive iron complexes), using argon here would likely be an unnecessary expense that yields diminishing returns compared to nitrogen.

Making the Right Choice for Your Goal

To achieve the desired material properties, you must match the furnace conditions to your specific substrate:

- If your primary focus is Cellulose/Chitosan Aerogels: Adhere strictly to a 300°C setpoint under Nitrogen, as this balances carbonization with the preservation of the porous, hydrophobic structure.

- If your primary focus is High Conductivity or Metal-Doped Materials: You will likely need to escalate conditions to 800°C under Argon, as higher thermal energy is required to graphitize polymers or transform metal complexes.

Ultimately, the tube furnace is not just a heater, but a precision tool for sculpting the chemical identity of your aerogel through atmospheric and thermal control.

Summary Table:

| Parameter | Specification for Cellulose/Chitosan | Purpose in Carbonization |

|---|---|---|

| Temperature | 300°C | Facilitates dehydrogenation & aromatization |

| Atmosphere | Nitrogen (N₂) | Prevents combustion & ensures pyrolysis |

| Cooling | Controlled | Preserves macroscopic porous architecture |

| Gas Flow | Continuous | Displaces oxygen to maintain inert environment |

| Result | Hydrophobic Skeleton | Enhances chemical stability and oil affinity |

Elevate Your Materials Research with KINTEK

Unlock the full potential of your carbonization processes with KINTEK's precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored specifically for delicate material transformations like aerogel carbonization.

Whether you require strict atmospheric control or customizable heat profiles for unique research needs, our lab high-temp furnaces ensure consistent, scalable results for scientists and industrial engineers alike.

Ready to optimize your lab’s efficiency? Contact us today to discuss your project requirements with our technical specialists.

Visual Guide

References

- Bernadeta Ayu Widyaningrum, Heri Septya Kusuma. Chitosan-Reinforced Carbon Aerogels from Oil Palm Fronds for Enhanced Oil Absorption and Silver Nanowires Loaded as Antimicrobial Activity. DOI: 10.21203/rs.3.rs-7269305/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What environmental conditions does a tube furnace provide for CFeS aerogels? Master Carbonization & Inert Protection

- What maintenance does a horizontal tube furnace require? Ensure Peak Performance and Safety

- How does a tube furnace facilitate the carbonization of ZIFs while preventing oxidation? Expert Insights

- How does a tube furnace ensure a controlled reaction environment? Achieve Precise Isothermal Oxidation Results

- Why is a heating rate of 3 °C/min typically set for a tube furnace? Optimize Iron Titanate Catalyst Synthesis

- What are some examples of tube furnace models and their ideal applications? Find Your Perfect Match for Precise Thermal Processing

- What is the primary function of a tube furnace during Ce-NiCoP phosphorization? Achieve Precise Catalyst Synthesis

- What is the function of an industrial tube furnace during the secondary carbonization of biomass? Achieve Precision.