The technical advantage of using an Entrained Flow Reactor (EFR) lies in its ability to accurately replicate the extreme thermal environment of industrial burners. By achieving heating rates of approximately 10^5 degrees Celsius per second, the EFR produces char that is physically and chemically consistent with char generated in large-scale operations.

The Entrained Flow Reactor bridges the gap between laboratory testing and industrial reality. It ensures that reactivity analysis is based on char with the correct pore structure, making combustion efficiency predictions significantly more reliable.

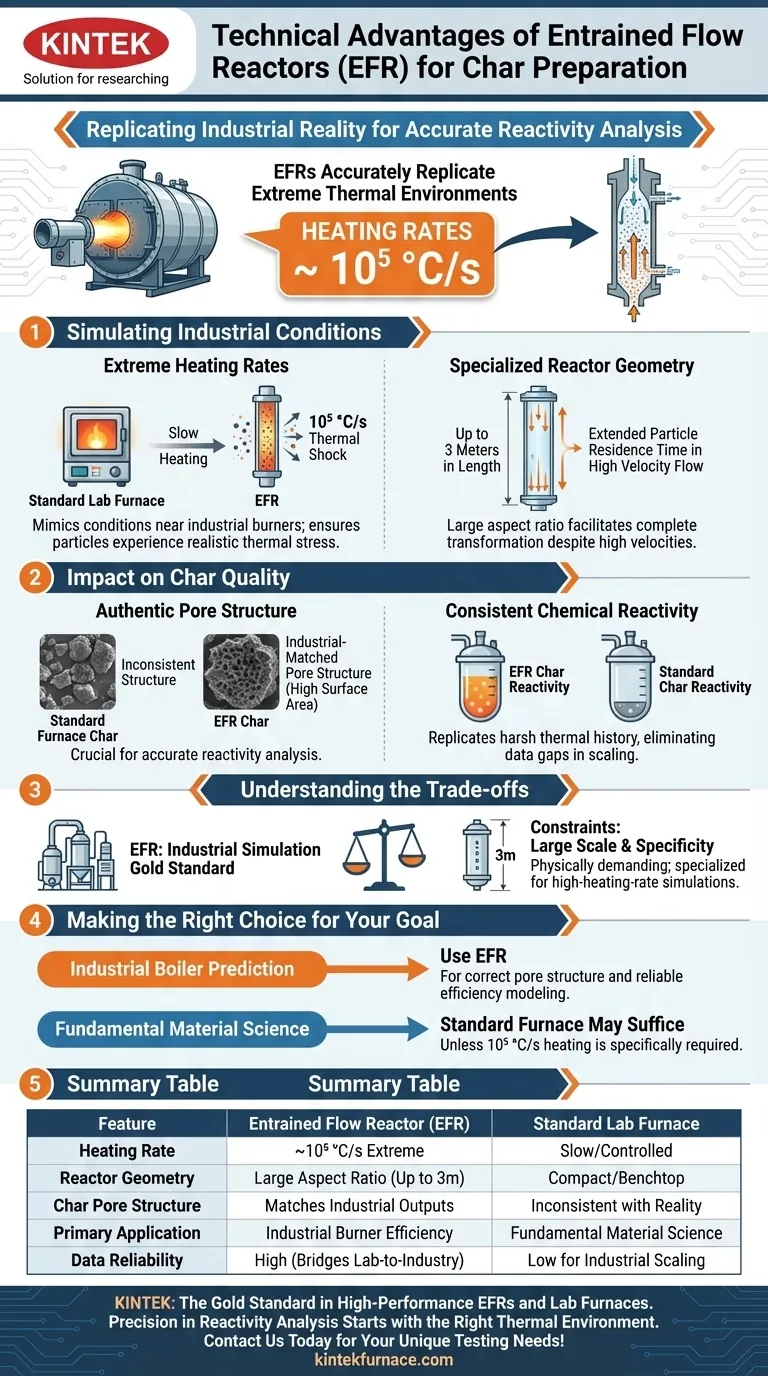

Simulating Industrial Conditions

To generate useful data for industrial applications, a reactor must mimic the harsh environment of a real boiler. The EFR achieves this through specific design choices.

Extreme Heating Rates

The defining capability of the EFR is its heating rate.

Standard laboratory furnaces often heat samples slowly. In contrast, the EFR subjects particles to a thermal shock of roughly 10^5 °C/s.

This rapid heating is critical because it mimics the conditions near industrial burners. It ensures the fuel particles experience the same thermal stress as they would in a real-world scenario.

Specialized Reactor Geometry

The EFR utilizes a unique large aspect ratio design to facilitate this environment.

The reaction space is significantly elongated, often featuring tubes up to 3 meters in length.

This geometry allows particles to remain entrained in the flow long enough to undergo complete transformation under specific thermal profiles, despite the high velocity of the system.

Impact on Char Quality

The thermal history of a fuel particle dictates its final properties. The EFR ensures those properties are representative.

Authentic Pore Structure

The speed at which coal or biomass is heated dramatically affects how volatiles escape and how pores form.

Char produced in an EFR possesses a pore structure that closely matches char from large-scale boilers.

Because the internal surface area (pores) drives reactivity, this structural consistency is vital for accurate analysis.

Consistent Chemical Reactivity

Reactivity is not just about material composition; it is about how that material interacts with its environment.

By replicating the harsh thermal conditions, the EFR ensures the chemical reactivity of the prepared char is consistent with industrial outputs.

This eliminates the "data gap" often seen when using char prepared in slow-heating fixed-bed reactors.

Understanding the Trade-offs

While the EFR is superior for industrial simulation, its design imposes specific constraints that users must acknowledge.

The Constraint of Scale

The reliance on a large aspect ratio means these reactors are physically demanding.

With reaction tubes reaching 3 meters, an EFR requires significantly more vertical space and infrastructure than compact benchtop units.

Specificity vs. Versatility

The EFR is a specialized tool designed for high-heating-rate simulations.

It is optimized for replicating burner conditions. It may not be the ideal choice for studies focusing on slow pyrolysis or low-temperature phenomena, as its core value proposition is the generation of high-thermal-stress char.

Making the Right Choice for Your Goal

To determine if an EFR is the right tool for your reactivity analysis, consider your end goals.

- If your primary focus is Industrial Boiler Prediction: Use an EFR to ensure your char has the correct pore structure and reactivity profile for reliable efficiency modeling.

- If your primary focus is Fundamental Material Science: Ensure you specifically require heating rates of 10^5 °C/s; otherwise, the large physical footprint of the 3-meter tube system may be unnecessary.

Ultimately, the Entrained Flow Reactor is the gold standard for transforming raw fuel into a representative char that yields truthful, scalable combustion data.

Summary Table:

| Feature | Entrained Flow Reactor (EFR) | Standard Lab Furnace |

|---|---|---|

| Heating Rate | ~10^5 °C/s (Extreme Thermal Shock) | Slow / Controlled Heating |

| Reactor Geometry | Large Aspect Ratio (Up to 3m Length) | Compact / Benchtop |

| Char Pore Structure | Matches Industrial Boiler Outputs | Inconsistent with Large-Scale Reality |

| Primary Application | Industrial Burner Efficiency Modeling | Fundamental Material Science |

| Data Reliability | High (Bridges Lab-to-Industry Gap) | Low for Industrial Scaling |

Precision in reactivity analysis starts with the right thermal environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Entrained Flow Reactors and a wide range of customizable lab high-temp furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are simulating industrial burners or conducting fundamental research, our systems provide the accuracy your laboratory demands. Contact KINTEK today to discuss your unique testing needs!

Visual Guide

References

- Krzysztof Czajka. Evaluation of the Reliability of Thermogravimetric Indices for Predicting Coal Performance in Utility Systems. DOI: 10.3390/en18133473

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What temperature control features do tube turnouts typically have? Achieve Precise Thermal Management for Your Lab

- What does the 'split' design in a Split Tube Furnace refer to? Unlock Easy Access and Faster Cooling

- What is the purpose of pre-treating quartz tube reactors? Achieve High-Purity CVT Crystal Growth with Precision

- How does a high-temperature tube furnace ensure environmental stability for SOEC? Precision Heat & Atmosphere Control

- What are the advantages of using a high-temperature tube furnace for rGO sensor fabrication? Precision & Performance

- What core process conditions does a vacuum tube furnace provide for FeCoNiCrAl coatings? Expert Annealing Guide

- What are tube furnaces made of? Choose the Right Material for Your Thermal Process

- What is the significance of expanding raw material applicability in tube furnaces? Unlock Versatility and Cost Savings