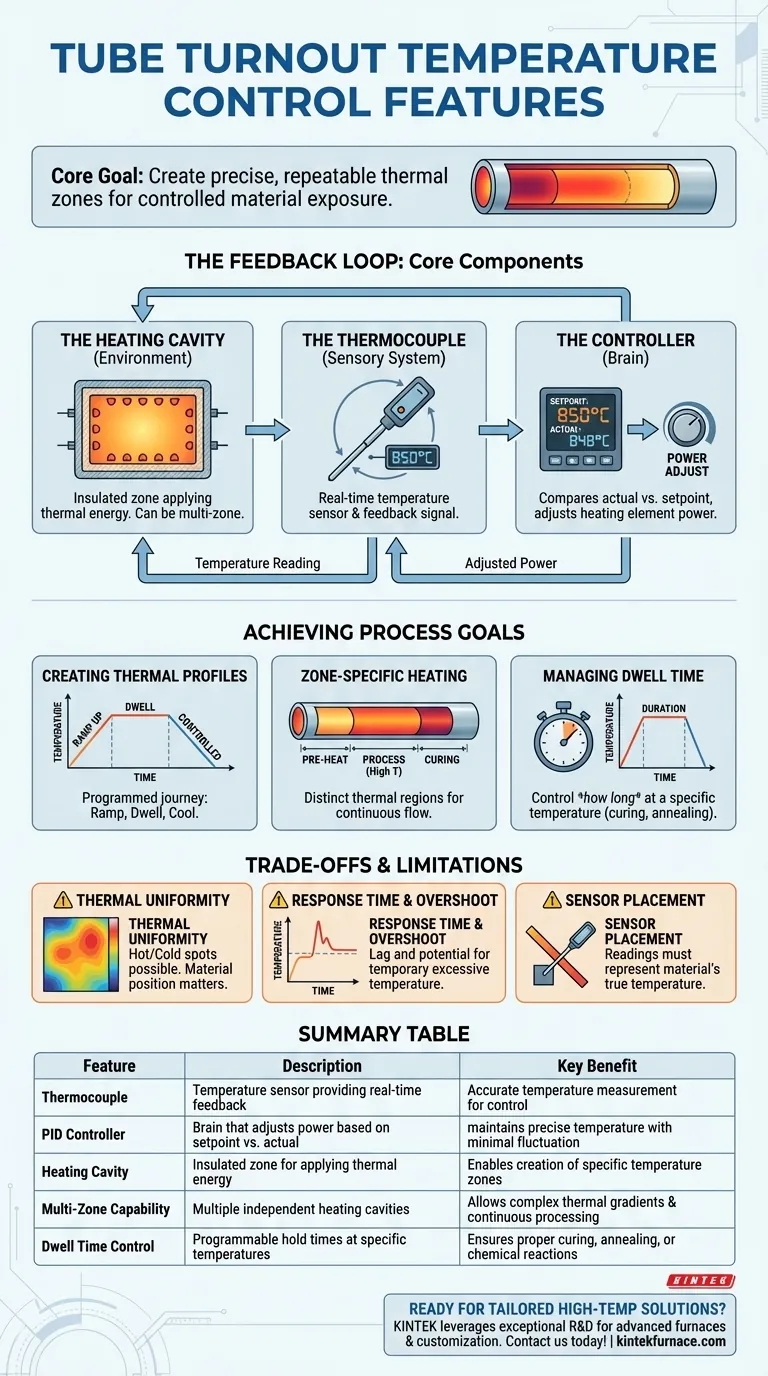

At its core, a tube turnout's temperature control relies on a system of thermocouple-controlled heating cavities. These components work in unison to create highly specific temperature zones, exposing materials to a calculated thermal profile for precise durations to achieve a desired processing outcome.

The fundamental goal of temperature control in a tube turnout is not merely to apply heat. It is to create precise, repeatable thermal zones that manage a material's exposure to different temperatures over specific timeframes, ensuring predictable and high-quality processing.

The Core Components of Temperature Control

To achieve precise thermal management, a tube turnout integrates three critical components into a feedback loop. Understanding how they interact is key to controlling your process.

The Heating Cavity: The Environment

A heating cavity is an insulated zone where thermal energy is applied to the material. A tube turnout can feature one or more of these cavities, each potentially acting as an independent temperature zone.

This multi-zone capability is what allows for the creation of complex temperature gradients along the path of the material.

The Thermocouple: The Sensory System

The thermocouple is the temperature sensor. It is a robust probe placed within the heating cavity to provide a real-time measurement of the actual temperature.

This measurement is the critical feedback signal. Without an accurate temperature reading from the thermocouple, true control is impossible.

The Controller: The Brain of the Operation

The thermocouple sends its temperature data to a controller, often a PID (Proportional-Integral-Derivative) controller. This unit continuously compares the actual temperature to your desired temperature (the "setpoint").

Based on any difference, the controller precisely adjusts the power sent to the heating elements within the cavity, either increasing or decreasing it to maintain the setpoint with high accuracy.

How Temperature Zones Achieve a Process Goal

The combination of these components allows for sophisticated process control that goes far beyond simple heating. It enables the execution of a specific thermal recipe.

Creating Thermal Profiles

A thermal profile is a material's temperature journey over time. The control system allows you to program this journey, such as rapidly ramping up to a specific temperature, holding it steady for a set "dwell time," and then cooling it at a controlled rate.

Zone-Specific Heating

With multiple heating cavities, you can create distinct thermal regions. A material can move from a pre-heating zone to a high-temperature processing zone and then to a curing zone, all within a single turnout and in a continuous flow.

Managing Dwell Time

The system doesn't just manage how hot it gets, but for how long. This control over dwell time is crucial for processes like curing, annealing, or triggering specific chemical reactions, where both temperature and time are critical variables.

Understanding the Trade-offs and Limitations

While powerful, these systems are not without their operational challenges. Awareness of these limitations is essential for troubleshooting and process optimization.

Thermal Uniformity Challenges

Achieving a perfectly uniform temperature throughout the entire volume of a heating cavity is difficult. "Hot spots" or "cold spots" can exist, potentially leading to inconsistent processing if the material's position is not carefully managed.

Response Time and Overshoot

There is a natural lag between the controller calling for heat and the cavity's thermal mass fully responding. A poorly tuned controller can "overshoot" the setpoint, temporarily exposing the material to excessive temperatures that could cause damage.

Sensor Placement is Critical

A thermocouple only measures the temperature at the specific point where its tip is located. If it's placed incorrectly—too close to a heating element or far from the material—its readings will not represent the true temperature the material is experiencing, leading to flawed process control.

Applying This to Your Process

Understanding the mechanics of temperature control allows you to tailor the system's performance to your specific objective.

- If your primary focus is process repeatability: Ensure your thermocouples are properly calibrated and your PID controller is tuned to minimize temperature fluctuations around the setpoint.

- If your primary focus is material integrity: Map the thermal profile carefully and program your controller to avoid temperature overshoots that could compromise sensitive materials.

- If your primary focus is throughput efficiency: Optimize your heating zones and dwell times to achieve the desired processing outcome in the shortest possible cycle time without sacrificing quality.

By viewing these features as a complete, interconnected system, you gain direct control over the quality and consistency of your final product.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Thermocouple | Temperature sensor providing real-time feedback | Accurate temperature measurement for control |

| PID Controller | Brain that adjusts power based on setpoint vs. actual temperature | Maintains precise temperature with minimal fluctuation |

| Heating Cavity | Insulated zone for applying thermal energy | Enables creation of specific temperature zones |

| Multi-Zone Capability | Multiple independent heating cavities | Allows complex thermal gradients and continuous processing |

| Dwell Time Control | Programmable hold times at specific temperatures | Ensures proper curing, annealing, or chemical reactions |

Ready to enhance your lab's efficiency with tailored high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced tube furnaces and other high-temperature systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for precise temperature control and repeatable results. Contact us today to discuss how we can support your material processing goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis