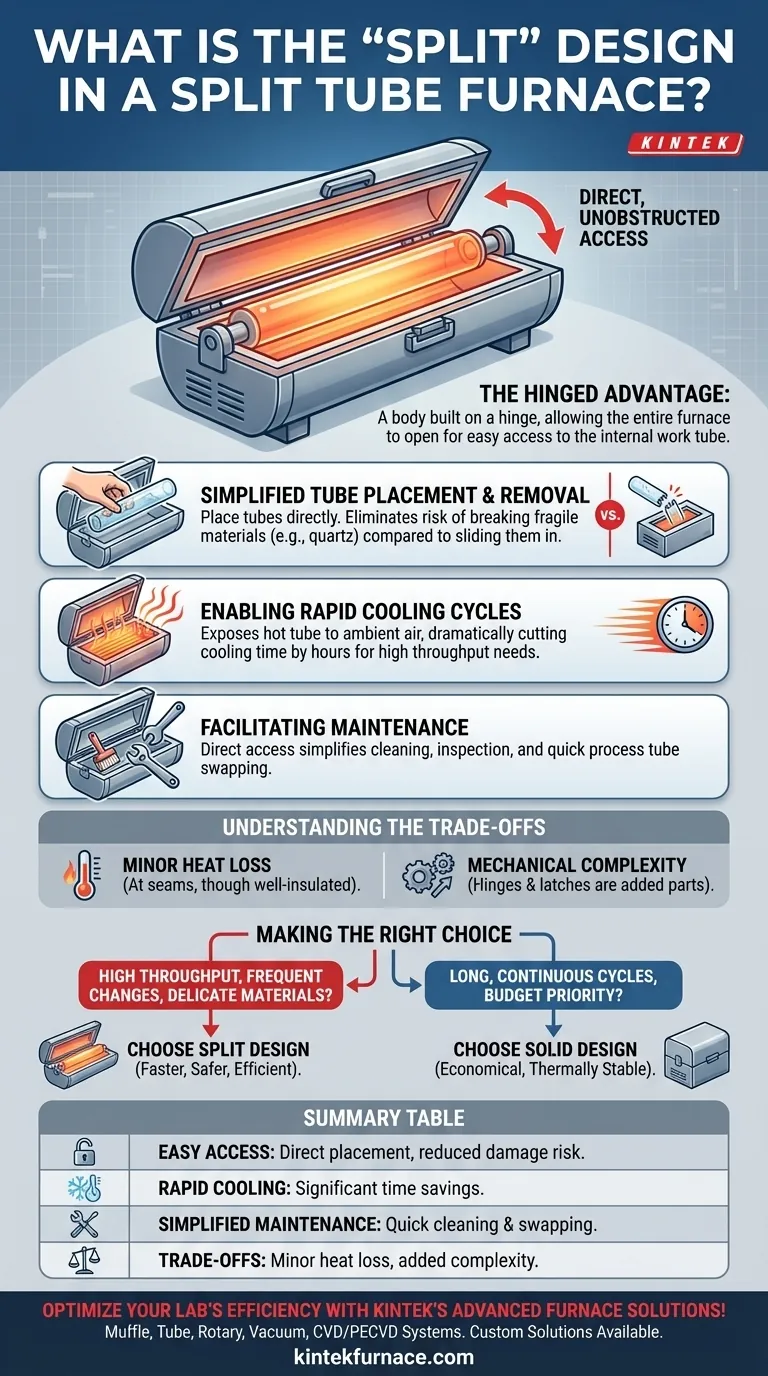

In simple terms, the 'split' design in a single-zone tube furnace refers to a body that is built on a hinge. This allows the entire furnace to open lengthwise into two halves, providing direct, unobstructed access to the internal work tube where the heating process takes place.

The core value of the split tube design is not merely about opening the furnace; it is about fundamentally changing how you interact with your experiment. It prioritizes ease of access, which translates into faster sample cycling, greater protection for delicate materials, and simplified maintenance.

The Core Function of the Split Design

A split tube furnace addresses the practical challenges of loading, unloading, and cooling samples within a high-temperature environment. Its hinged body is a direct solution to the limitations of a solid, one-piece furnace.

Simplifying Tube Placement and Removal

In a traditional solid furnace, the process tube must be carefully slid in from one end. This can be difficult and risks breaking the tube, especially if it is long, made of a fragile material like quartz, or contains a complex sample arrangement.

The split design eliminates this risk. You simply open the furnace, place the work tube and its contents directly onto the lower half, and close the top half over it.

Enabling Rapid Cooling Cycles

Perhaps the most significant operational advantage is accelerated cooling. Once a heating cycle is complete, you can open the furnace body.

This immediately exposes the hot work tube to ambient air, allowing it to cool dramatically faster than it would inside a heavily insulated, solid furnace chamber. For labs with high throughput needs, this can save hours between experiments.

Facilitating Maintenance

Direct access to the furnace interior and the work tube simplifies cleaning and inspection. Swapping out different process tubes for different experiments becomes a quick and straightforward task.

Understanding the Trade-offs

While highly advantageous, the split design is not without considerations. Its benefits are weighed against minor trade-offs in design and performance.

Potential for Heat Loss

The seam where the two halves of the furnace meet can be a source of minor heat loss. While quality manufacturers engineer this junction with overlapping insulation to ensure excellent temperature uniformity, a solid, one-piece body is inherently more sealed.

Mechanical Complexity

The addition of hinges and latching mechanisms introduces mechanical components. Although robustly built in high-quality furnaces, these are parts that are not present on a simpler, solid furnace design.

When a Solid Furnace Might Be Suitable

A non-split, solid tube furnace can be a perfectly adequate and often more economical choice. It excels in applications involving long, continuous heating cycles where the sample is loaded once and left for an extended period, and rapid cooling is not a priority.

Making the Right Choice for Your Goal

The decision between a split and solid tube furnace should be driven entirely by your specific application and workflow.

- If your primary focus is high throughput and frequent sample changes: The rapid cooling and easy tube access of a split furnace will significantly improve your lab's efficiency.

- If you are working with delicate materials or complex setups inside the tube: The ability to carefully place the tube makes the split design the safer and more practical choice.

- If your main priority is budget and running simple, long-duration processes: A solid tube furnace provides excellent thermal performance and may be the more cost-effective option.

Ultimately, choosing the right furnace design is about matching the tool to the specific demands of your work.

Summary Table:

| Feature | Description |

|---|---|

| Easy Access | Hinged body opens lengthwise for direct tube placement, reducing risk of damage to fragile materials. |

| Rapid Cooling | Exposes work tube to ambient air, cutting cooling time significantly for high-throughput experiments. |

| Simplified Maintenance | Allows quick cleaning, inspection, and tube swapping without complex disassembly. |

| Trade-offs | Minor heat loss at seams and added mechanical complexity compared to solid furnaces. |

Optimize your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable split tube furnaces that offer easy access, rapid cooling, and deep customization to meet your unique experimental needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all designed to enhance productivity and protect your materials. Contact us today to discuss how we can tailor a solution for you!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability