The ability of a tube furnace to handle a wider range of raw materials signifies a fundamental shift in its operational and economic value. It transforms the furnace from a highly specialized, single-purpose instrument into a versatile processing platform, unlocking significant flexibility for research, production, and supply chain management across numerous industries.

The core significance is not just about adding more material options. It's about decoupling a high-value process from a dependency on a single, often expensive or volatile, raw material source, thereby increasing economic resilience and opening new avenues for innovation.

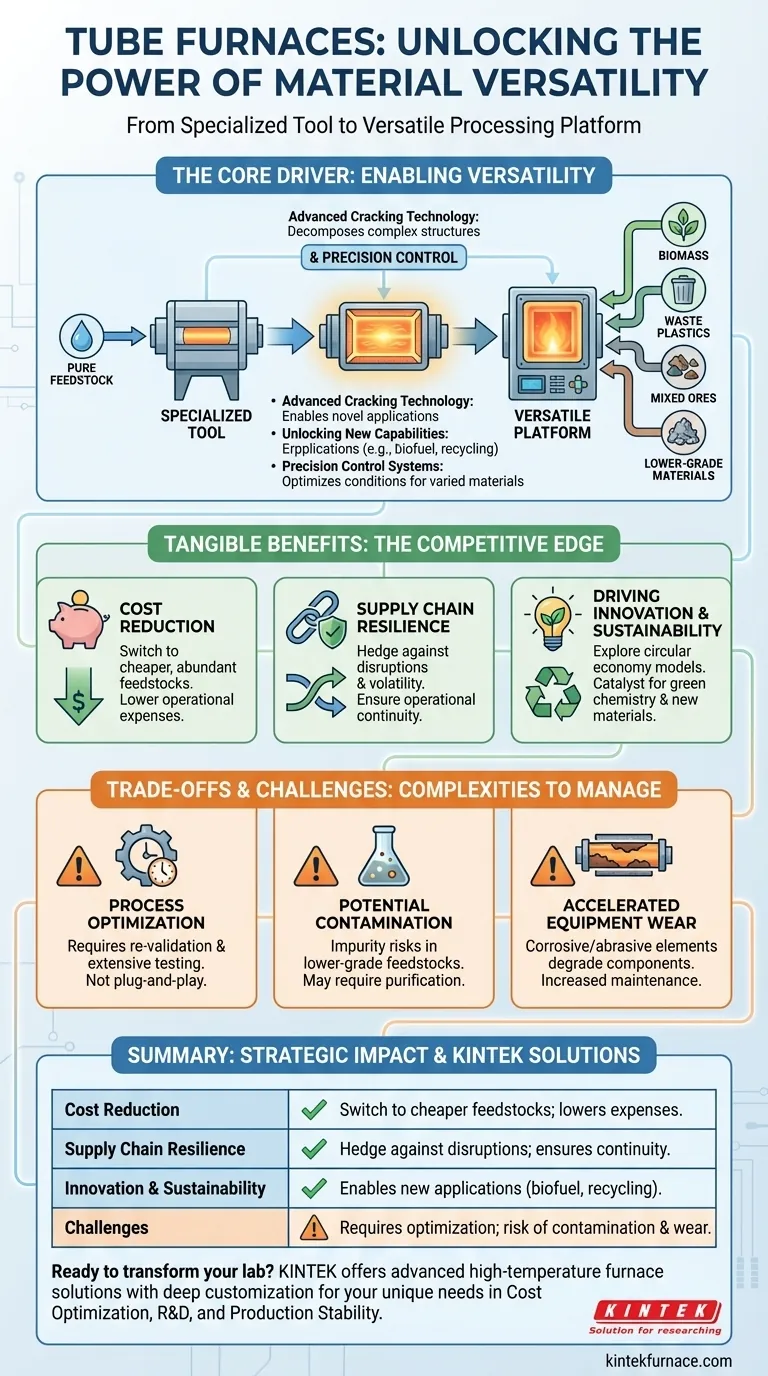

The Core Driver: From Specialized Tool to Versatile Platform

Historically, many thermal processes were rigidly designed around a specific, high-purity feedstock. Expanding material applicability fundamentally changes this paradigm, driven by advances in furnace technology and process control.

The Impact of Advanced Cracking Technology

Modern cracking technologies are the engine behind this enhanced versatility. They allow for the effective thermal decomposition of more complex or varied molecular structures than ever before.

This means the furnace can successfully process not just traditional, pure chemical precursors but also mixed feedstocks, lower-grade materials, or even waste streams, converting them into valuable products.

Unlocking New Process Capabilities

The ability to handle different materials is not just about substitution; it's about enabling entirely new applications.

A furnace that can process biomass, waste plastics, or different mineral ores opens up research and production in fields like biofuel development, chemical recycling, and advanced materials synthesis.

The Role of Precision Control Systems

This flexibility would be impossible without sophisticated process control. Modern tube furnaces integrate precise temperature, atmosphere, and flow rate controls that can be adjusted for different materials.

This allows operators to create the ideal conditions needed to handle feedstocks with varying melting points, reactivity, and off-gassing characteristics, ensuring consistent and predictable outcomes.

The Tangible Benefits of Material Versatility

The shift toward material-agnostic processing delivers clear, measurable advantages in cost, resilience, and innovation.

Significant Cost Reduction

The most immediate benefit is economic. A process is no longer tied to a single, high-purity, and potentially expensive raw material.

Operators can switch to more abundant, lower-cost, or opportunistically sourced feedstocks without compromising the end product, directly reducing operational expenditures.

Enhanced Supply Chain Resilience

Relying on a single raw material source creates significant business risk from price volatility, geopolitical instability, or supply disruptions.

Material versatility acts as a powerful hedge. If a primary feedstock becomes unavailable or uneconomical, production can pivot to a viable alternative, ensuring operational continuity.

Driving Sustainability and Innovation

For research labs and forward-thinking industries, this capability is a catalyst for sustainability. It allows for the exploration of circular economy models by testing waste-to-value pathways.

Being able to process materials like reclaimed electronic components or agricultural waste allows a standard tube furnace to become a critical tool for green chemistry and sustainable materials science.

Understanding the Trade-offs and Challenges

While incredibly beneficial, expanding raw material use is not without its complexities. A clear understanding of the trade-offs is essential for successful implementation.

The Complexity of Process Optimization

Using a new raw material is not a simple "plug-and-play" operation. Each new feedstock requires careful re-validation of the entire process.

This involves extensive testing to determine the optimal temperature profile, gas flow rates, and residence time needed to achieve the desired outcome, which requires time and analytical resources.

Potential for Increased Contamination

Lower-grade or alternative feedstocks often contain impurities not present in their high-purity counterparts.

These contaminants can impact the purity of the final product, potentially requiring additional downstream purification steps. They can also introduce side reactions that affect process yield and efficiency.

Accelerated Equipment Wear and Tear

Alternative raw materials may contain corrosive or abrasive elements that can accelerate the degradation of the furnace tube and other components.

This can lead to increased maintenance costs and a shorter lifespan for critical parts, a factor that must be weighed against the savings from cheaper feedstock.

Making the Right Choice for Your Goal

To leverage this capability effectively, align your strategy with your primary objective.

- If your primary focus is cost optimization: Prioritize sourcing and qualifying lower-cost alternative feedstocks, but ensure you budget for the necessary process re-optimization and testing.

- If your primary focus is research and development: Use the furnace's versatility to explore novel chemical pathways and test the viability of sustainable or unconventional materials for new applications.

- If your primary focus is production stability: Develop protocols for at least one secondary feedstock to insulate your operations from supply chain disruptions and price shocks.

Ultimately, expanding raw material applicability transforms a tube furnace from a simple piece of heating equipment into a strategic asset for navigating a complex and evolving industrial landscape.

Summary Table:

| Aspect | Key Points |

|---|---|

| Cost Reduction | Switch to cheaper, abundant feedstocks; lowers operational expenses. |

| Supply Chain Resilience | Hedge against disruptions with alternative materials; ensures continuity. |

| Innovation & Sustainability | Enables new applications like biofuel research and waste recycling. |

| Challenges | Requires process re-optimization; risk of contamination and equipment wear. |

Ready to transform your lab with a versatile tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether you're focused on cost optimization, R&D innovation, or production stability. Contact us today to discuss how our tailored solutions can enhance your efficiency and drive your projects forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents