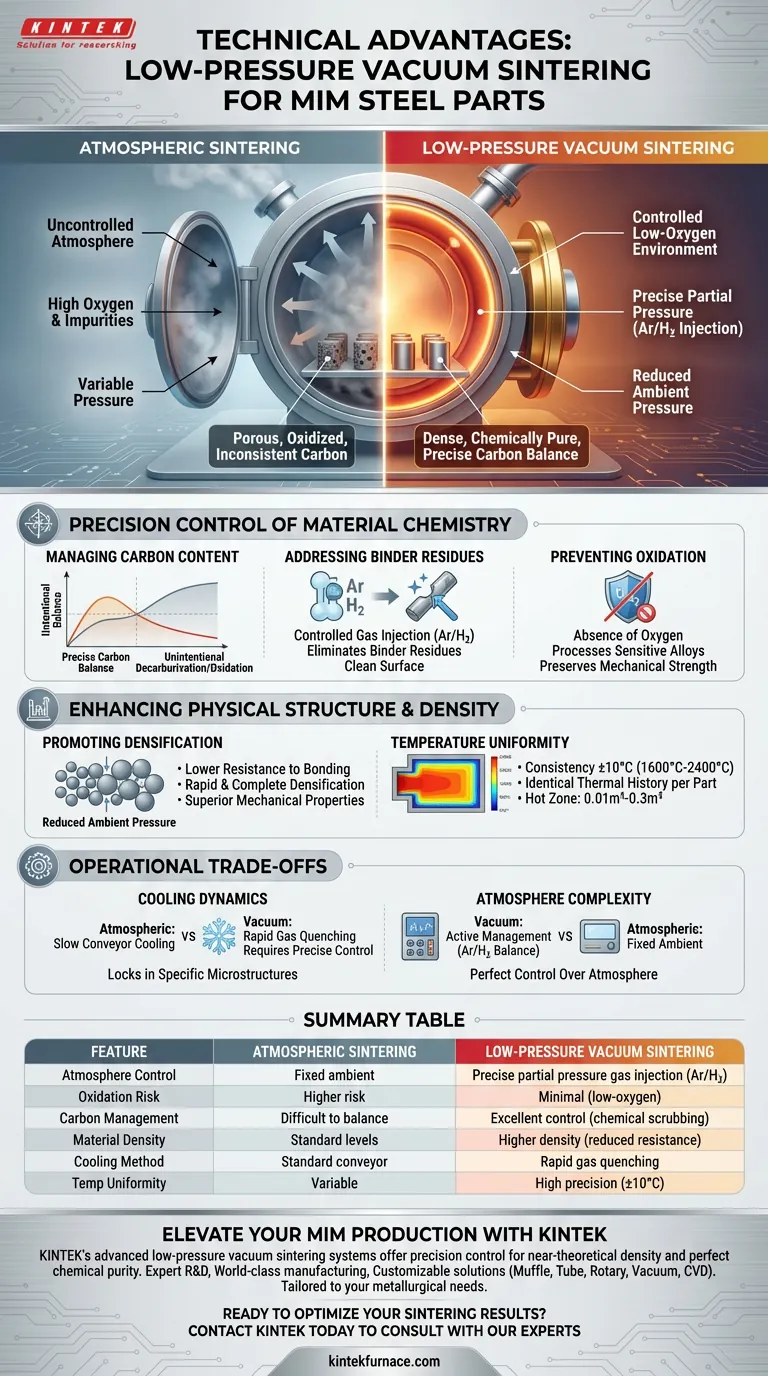

The primary technical advantage of low-pressure vacuum sintering is its ability to create a controlled, low-oxygen environment that significantly improves the density and chemical purity of Metal Injection Molding (MIM) parts.

Unlike atmospheric pressure sintering, vacuum furnaces allow for precise manipulation of internal pressure and gas composition. This capability is critical for managing carbon content, eliminating binder residues, and preventing oxidation in sensitive steel grades.

Core Takeaway: Achieving high-performance MIM parts requires mastering the removal of binders and the prevention of voids. Low-pressure vacuum sintering solves this by reducing ambient pressure to promote densification while utilizing controlled gas injection to chemically scrub carbon residues and prevent oxidation.

Precision Control of Material Chemistry

Managing Carbon Content

The most critical challenge in MIM is maintaining the correct carbon balance after binder removal. Low-pressure vacuum furnaces provide a low oxygen potential environment.

This environment prevents the unintentional decarburization or oxidation of the steel, ensuring the final carbon content aligns strictly with the alloy's specifications.

Addressing Binder Residues

Atmospheric furnaces often struggle with "carbon excess" caused by trapped binder materials. Vacuum furnaces address this by allowing for the controlled injection of inert or reducing gases, such as argon or hydrogen.

These gases actively react with or sweep away residual binders. This fine-tuning capability ensures the surface characteristics of the part remain clean and defect-free.

Preventing Oxidation

Standard atmospheric sintering poses a risk to reactive materials. The absence of oxygen in a vacuum furnace allows for the processing of steel grades that are highly sensitive to oxidation.

This capability is essential for high-performance alloys where even microscopic oxidation can compromise mechanical strength.

Enhancing Physical Structure and Density

Promoting Densification

Achieving full density is the ultimate goal of sintering. By reducing the ambient pressure, vacuum furnaces lower the resistance to particle bonding.

This reduction in pressure promotes rapid and complete densification of the steel parts, leading to superior mechanical properties compared to parts processed at atmospheric pressure.

Temperature Uniformity

Consistency is vital for batch production. These furnaces maintain temperature uniformity within ±10°C, even at extreme temperatures ranging from 1600°C up to 2400°C.

This ensures that every part in the batch, regardless of its position in the hot zone (ranging from 0.01m³ to 0.3m³), experiences the exact same thermal history.

Operational Trade-offs: Vacuum vs. Atmospheric

Cooling Dynamics

Atmospheric sintering typically relies on conveyor furnaces with standard cooling rates. In contrast, vacuum furnaces are often paired with gas quenching systems.

This allows parts to cool down significantly faster than they would in conveyor furnaces. Rapid cooling can be advantageous for locking in specific microstructures, though it requires precise control to avoid thermal shock.

Atmosphere Complexity

While atmospheric furnaces rely on a consistent ambient environment, vacuum furnaces require active management.

The operator must balance the vacuum level with the specific partial pressures of injected gases (Ar/H2). This adds a layer of technical complexity but offers the reward of perfect control over the sintering atmosphere.

Making the Right Choice for Your Goal

To maximize the quality of your MIM steel parts, align your furnace choice with your specific metallurgical requirements.

- If your primary focus is Chemical Purity: Use vacuum sintering to utilize partial pressure gas injection (Ar/H2) for the precise removal of binder residues and carbon control.

- If your primary focus is High Density: Rely on the reduced ambient pressure of vacuum furnaces to promote tighter particle bonding and pore closure.

- If your primary focus is Oxidation Sensitivity: Choose vacuum sintering to eliminate oxygen entirely, enabling the processing of sensitive high-performance alloys.

Ultimately, low-pressure vacuum sintering transforms the sintering process from a simple heating step into a tunable chemical reaction, guaranteeing superior density and surface integrity.

Summary Table:

| Feature | Atmospheric Sintering | Low-Pressure Vacuum Sintering |

|---|---|---|

| Atmosphere Control | Fixed ambient environment | Precise partial pressure gas injection (Ar/H2) |

| Oxidation Risk | Higher risk in sensitive alloys | Minimal due to low-oxygen environment |

| Carbon Management | Difficult to balance binder residues | Excellent control via chemical scrubbing |

| Material Density | Standard density levels | Higher density through reduced resistance |

| Cooling Method | Standard conveyor cooling | Rapid gas quenching for microstructure control |

| Temp Uniformity | Variable based on furnace size | High precision (typically within ±10°C) |

Elevate Your MIM Production with KINTEK

Don't settle for inconsistent material properties. KINTEK’s advanced low-pressure vacuum sintering systems offer the precision control needed to achieve near-theoretical density and perfect chemical purity for your MIM steel parts.

Backed by expert R&D and world-class manufacturing, KINTEK provides a comprehensive range of customizable solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need to eliminate oxidation or master carbon balance, our lab high-temp furnaces are tailored to your unique metallurgical needs.

Ready to optimize your sintering results?

Contact KINTEK Today to Consult with Our Experts

Visual Guide

References

- Jorge Luis Braz Medeiros, Luciano Volcanoglo Biehl. Effect of Sintering Atmosphere Control on the Surface Engineering of Catamold Steels Produced by MIM: A Review. DOI: 10.3390/surfaces9010007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Spark Plasma Sintering SPS Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What is the purpose of using an industrial vacuum resistance furnace? Enhancing Ti-33Mo-0.2C Alloy Performance

- Why is a high-vacuum probe station necessary for SnS2 analysis? Ensure Pure Electrical Characterization

- What are the maintenance requirements for a vacuum furnace when not in use? Protect Your Investment with Proper Storage

- What are the key advantages of using a vacuum sintering furnace? Achieve High-Purity, Dense Materials with Superior Control

- What is the function of a vacuum drying oven in PDCPD processing? Achieve Pore-Free Composite Excellence

- What is the core technical mechanism of low-oxygen brazing? Master Oxide Decomposition for Perfect Bonds

- What applications does a vacuum melting furnace have in research? Unlock High-Purity Material Development

- Why is a high-vacuum ultra-high temperature annealing furnace required for studying deformed tungsten single crystals?