The primary purpose of using an industrial vacuum resistance furnace for the final heat treatment of Ti-33Mo-0.2C is to provide a controlled environment that simultaneously relieves internal stresses and stabilizes the alloy's microstructure.

Specifically, this process involves annealing the alloy at 850°C. The furnace's vacuum environment is critical during this phase to prevent surface oxidation, ensuring the material retains a stable, single beta-phase structure and excellent surface quality after the rigors of hot rolling.

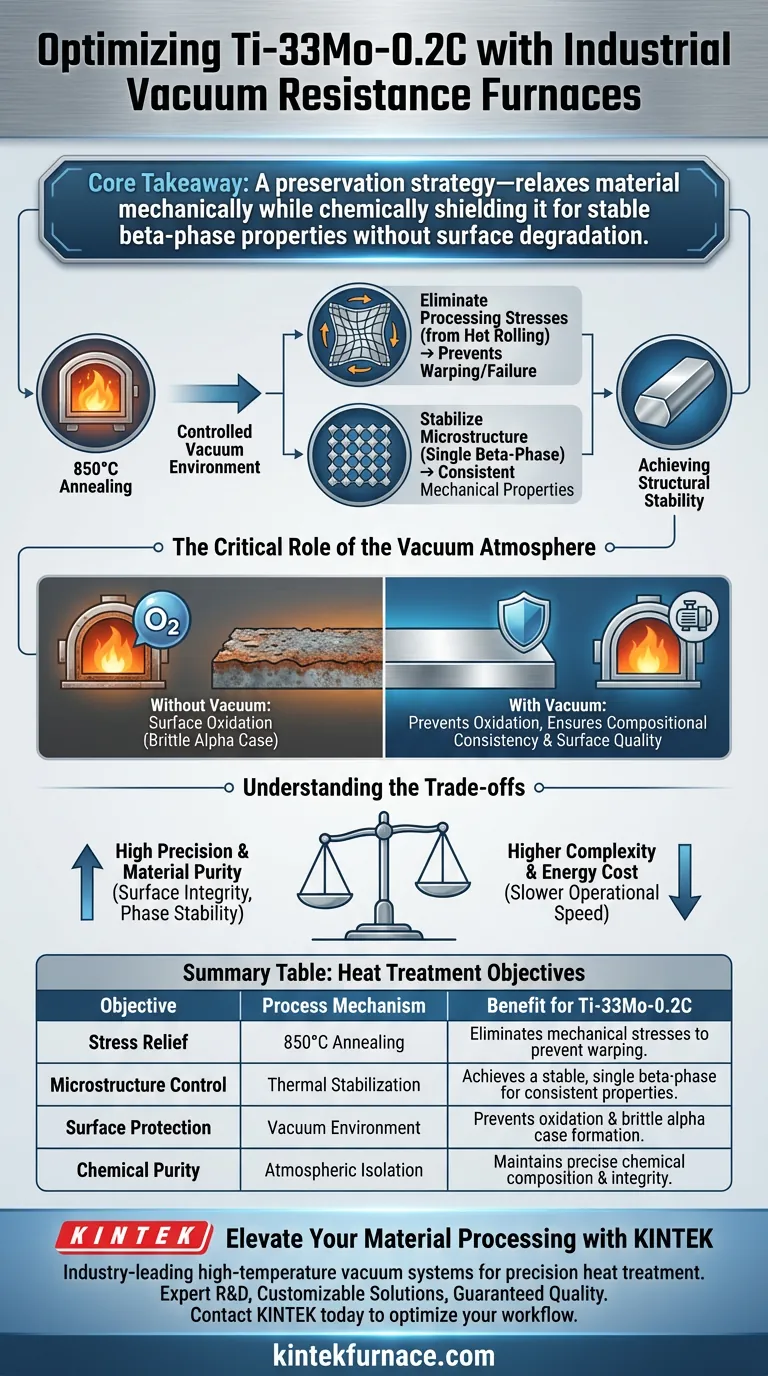

Core Takeaway: This heat treatment step is not just about temperature; it is a preservation strategy. It relaxes the material mechanically after processing while chemically shielding it to lock in the desired single beta-phase properties without surface degradation.

Achieving Structural Stability

Eliminating Processing Stresses

The Ti-33Mo-0.2C alloy undergoes hot rolling during its manufacturing, a process that introduces significant internal mechanical stresses.

Stress relief is the immediate mechanical goal of this heat treatment. By subjecting the alloy to a precise annealing temperature of 850°C, the furnace allows the material to relax, eliminating these residual stresses that could otherwise lead to warping or failure in service.

Stabilizing the Microstructure

Beyond stress relief, the thermal cycle is designed to modify the alloy's crystalline structure.

The treatment aims to achieve a stable, single beta-phase structure. Stabilizing this specific phase is essential for ensuring the alloy exhibits the consistent mechanical properties required for its final application.

The Critical Role of the Vacuum Atmosphere

Preventing Surface Oxidation

Titanium alloys are highly reactive at elevated temperatures. Without protection, exposure to heat would cause immediate degradation of the material's surface.

The vacuum resistance furnace provides a protective atmosphere that eliminates the presence of oxygen. This prevents the formation of a brittle oxide layer (alpha case), ensuring the final product maintains excellent surface quality.

Ensuring Compositional Consistency

The vacuum environment does more than protect the surface; it preserves the alloy's chemical integrity.

By isolating the material from atmospheric contaminants, the furnace ensures compositional stability. This guarantees that the precise chemical balance achieving during the earlier melting stages is not altered during the final thermal processing.

Understanding the Trade-offs

The Cost of Precision

While a vacuum resistance furnace offers superior control, it is a complex and energy-intensive solution compared to standard air or atmosphere furnaces.

You are trading operational speed and lower costs for material purity. Using this equipment implies that the surface integrity and phase stability of the Ti-33Mo-0.2C alloy are non-negotiable requirements for the application.

Sensitivity to Parameters

The success of this process relies heavily on the strict maintenance of the vacuum and temperature profile.

Any breach in the vacuum integrity or deviation from the 850°C setpoint can lead to incomplete stress relief or surface contamination. The "precise temperature-controlled environment" is a strict requirement, not merely a feature.

Making the Right Choice for Your Goal

The use of this specific furnace technology allows you to optimize the alloy for different priorities within the bounds of the 850°C anneal.

- If your primary focus is Structural Integrity: Prioritize the precision of the temperature hold time to ensure complete elimination of internal stresses and full transformation to the single beta-phase.

- If your primary focus is Surface Quality: Prioritize the depth and stability of the vacuum level to absolutely minimize oxidation, eliminating the need for aggressive post-treatment machining.

Success with Ti-33Mo-0.2C relies on using the vacuum furnace to decouple thermal treatment from chemical reaction, ensuring the alloy is as strong and pure as possible.

Summary Table:

| Heat Treatment Objective | Process Mechanism | Benefit for Ti-33Mo-0.2C |

|---|---|---|

| Stress Relief | 850°C Annealing | Eliminates mechanical stresses from hot rolling to prevent warping. |

| Microstructure Control | Thermal Stabilization | Achieves a stable, single beta-phase for consistent mechanical properties. |

| Surface Protection | Vacuum Environment | Prevents surface oxidation and the formation of a brittle alpha case. |

| Chemical Purity | Atmospheric Isolation | Maintains precise chemical composition and material integrity. |

Elevate Your Material Processing with KINTEK

Precision is non-negotiable when treating high-performance alloys like Ti-33Mo-0.2C. KINTEK provides industry-leading high-temperature vacuum systems designed to deliver the exact 850°C environment and deep vacuum levels required for stress relief and phase stabilization.

Why choose KINTEK?

- Expert R&D: Our Muffle, Tube, Rotary, Vacuum, and CVD systems are backed by advanced manufacturing and engineering expertise.

- Customizable Solutions: We tailor our lab and industrial furnaces to meet your unique atmospheric and thermal profile needs.

- Guaranteed Quality: Prevent oxidation and ensure structural integrity with our superior temperature control technology.

Contact KINTEK today to optimize your heat treatment workflow and experience the difference that specialized vacuum technology can make for your lab or production line.

Visual Guide

References

- W. Szkliniarz, Agnieszka Szkliniarz. The Role of Titanium Carbides in Forming the Microstructure and Properties of Ti-33Mo-0.2C Alloy. DOI: 10.3390/coatings15050546

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the specific purpose of using a vacuum high-temperature furnace for powder pre-treatment? Ensure Sharp Interfaces

- Why is a laboratory vacuum oven with nitrogen protection used for alumina dehydration? Ensure High-Purity Surfaces

- How does a high vacuum annealing furnace contribute to 2D Bi2Te3-Sb2Te3 superlattices? Precision Thermal Engineering

- How do thermal imagers and hybrid AI models facilitate leak detection? 92% Accuracy in Industrial Furnaces

- Why is the high vacuum environment critical for TB8 titanium matrix composites? Ensuring High-Strength Bonding

- How do custom vacuum furnaces address industry-specific challenges? Tailored Solutions for Aerospace, Medical & Energy

- What is the function of a heating furnace in the distillation separation process of a High Vacuum Unit (HVU)?

- What role do vacuum furnaces play in powder metallurgy? Achieve High-Purity, Dense Metal Parts