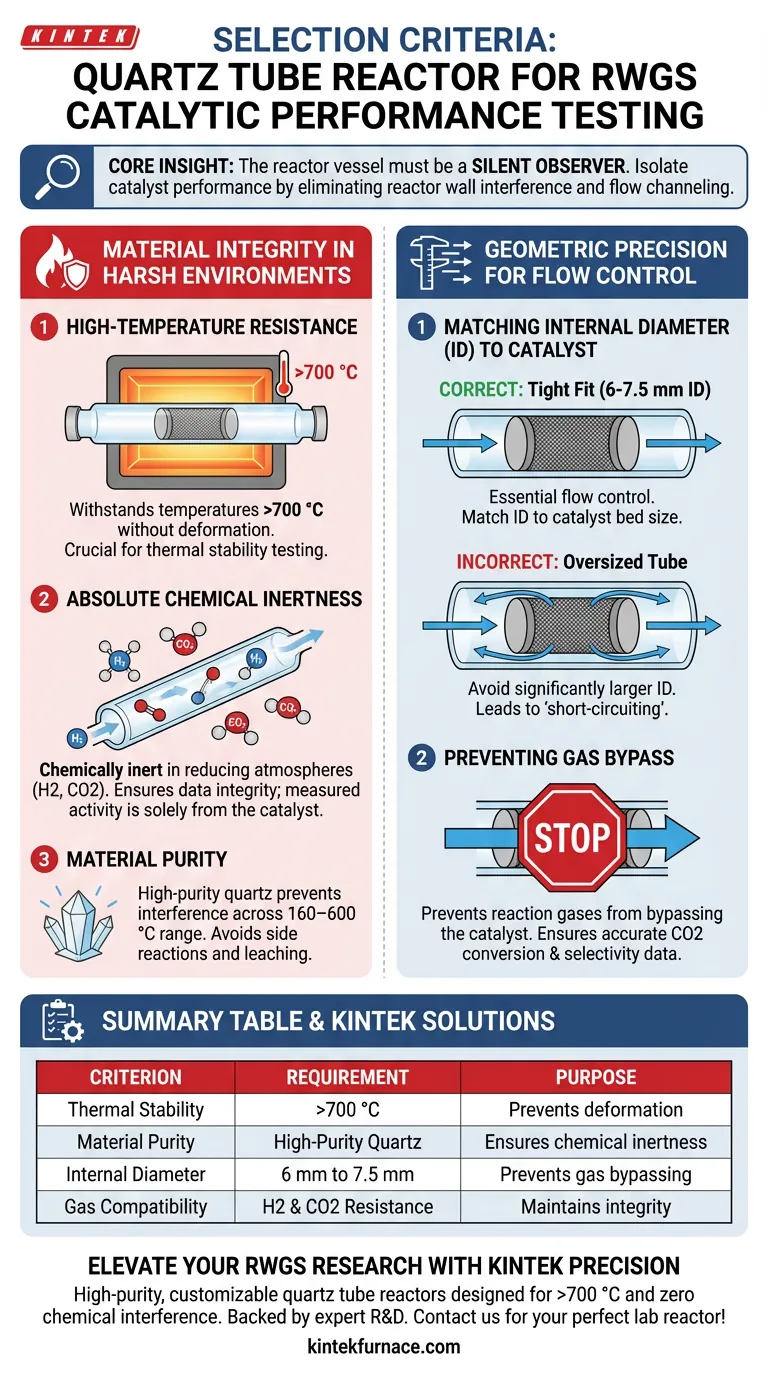

To select the correct quartz tube reactor for RWGS testing, you must prioritize three critical factors: thermal stability exceeding 700 °C, absolute chemical inertness in reducing atmospheres, and precise internal dimensions. Specifically, a narrow internal diameter (typically around 6 mm to 7.5 mm) is essential to match the catalyst bed size, ensuring the reaction gas passes through the catalyst rather than bypassing it.

Core Insight: The reactor vessel must act as a silent observer, not a participant. Your selection strategy focuses on isolating the catalyst's performance by eliminating two major sources of experimental error: chemical interference from the reactor walls and physical flow channeling around the catalyst bed.

Material Integrity in Harsh Environments

Requirement for High-Temperature Resistance

The Reverse Water Gas Shift (RWGS) reaction operates under intense thermal conditions.

The quartz tube selected must withstand temperatures exceeding 700 °C without softening or deforming. This thermal ceiling allows for the rigorous testing of thermal stability inherent to high-entropy oxide catalysts.

Absolute Chemical Inertness

The reactor environment involves high temperatures and a reducing atmosphere containing Hydrogen (H2) and Carbon Dioxide (CO2).

It is critical that the quartz material remains chemically inert and does not react with these gases or the catalyst itself. This ensures that any measured catalytic activity is derived solely from the catalyst, maintaining data integrity.

The Role of Material Purity

High-purity quartz is required to prevent interference across a broad testing range (often 160–600 °C).

Impurities in lower-grade quartz could potentially catalyze side reactions or leach into the sample, skewing the results of the performance test.

Geometric Precision for Flow Control

Matching Internal Diameter to Catalyst

There is a direct relationship between the tube's internal diameter (ID) and the physical form of your catalyst (e.g., Nickel foam discs).

If using 6 mm foam discs, the quartz tube must have a corresponding narrow ID (approximately 6–7.5 mm). This tight tolerance is not merely for fit; it is a critical flow control mechanism.

Preventing Gas Bypass

The most common mechanical failure in fixed-bed reactor testing is short-circuiting.

If the internal diameter is significantly larger than the catalyst bed, reaction gases will flow through the gap of least resistance rather than through the catalyst. This results in inaccurate CO2 conversion rates and flawed selectivity data.

Common Pitfalls to Avoid

The "Oversized Tube" Error

Using a standard, wide-bore reactor tube for small-scale catalyst testing is a frequent mistake.

Even a small gap between the catalyst bed and the tube wall allows gas to bypass the active material, leading to a massive underestimation of catalytic activity.

Ignoring Thermal Headroom

Selecting a tube rated exactly for your operating temperature (e.g., 600 °C) leaves no margin for safety.

Always select quartz capable of exceeding your maximum experimental temperature (aiming for >700 °C capability) to account for localized hot spots within the catalyst bed during the reaction.

Making the Right Choice for Your Goal

When specifying your quartz tube, align the specifications with the precision required for your data:

- If your primary focus is accurate conversion data: Prioritize a tube ID that perfectly matches your catalyst support (e.g., Ni foam) to strictly eliminate gas bypass.

- If your primary focus is high-temperature stability testing: Prioritize high-grade quartz certified for long-duration exposure to temperatures above 700 °C to prevent structural failure.

Select the reactor that renders itself invisible to the experiment, leaving only the true performance of the catalyst exposed.

Summary Table:

| Criterion | Requirement | Purpose |

|---|---|---|

| Thermal Stability | >700 °C | Prevents deformation during high-temp catalytic testing |

| Material Purity | High-Purity Quartz | Ensures chemical inertness and eliminates side reactions |

| Internal Diameter | 6 mm to 7.5 mm | Matches catalyst bed size to prevent gas bypassing |

| Gas Compatibility | H2 & CO2 Resistance | Maintains integrity in harsh reducing atmospheres |

Elevate Your RWGS Research with KINTEK Precision

Don’t let reactor interference compromise your catalytic data. KINTEK provides high-purity, customizable quartz tube reactors designed to withstand temperatures exceeding 700 °C while ensuring zero chemical interference.

Backed by expert R&D and manufacturing, KINTEK offers a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need precise internal diameters to eliminate gas bypass or specialized high-temp lab furnaces, our solutions are tailored to your unique research needs.

Contact us today to find the perfect reactor for your lab!

Visual Guide

References

- Ayano Taniguchi, Kazuya Kobiro. Low-temperature synthesis of porous high-entropy (CoCrFeMnNi)<sub>3</sub>O<sub>4</sub> spheres and their application to the reverse water–gas shift reaction as catalysts. DOI: 10.1039/d3dt04131j

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the specific functions of a vertical alumina tube reactor? Key Roles in Gasification Kinetics Research

- Why is precise temperature control important in a tubular furnace? Ensure Material Consistency and Quality

- What role does a tube furnace play in converting nickel precursors? Master Thermal Reduction in Argon Atmospheres

- Why is a high-temperature tube furnace used for SNCB preparation? Optimize Nitrogen-Doped Porous Carbon Synthesis

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- Why is environmental control in a high-temperature tube furnace necessary during NVP/C synthesis? Key to Success

- What factors should be considered when choosing a tube furnace? Key Selection Criteria for Optimal Performance

- How does an atmosphere tube furnace achieve precise temperature control? Master Temperature Stability for Your Lab