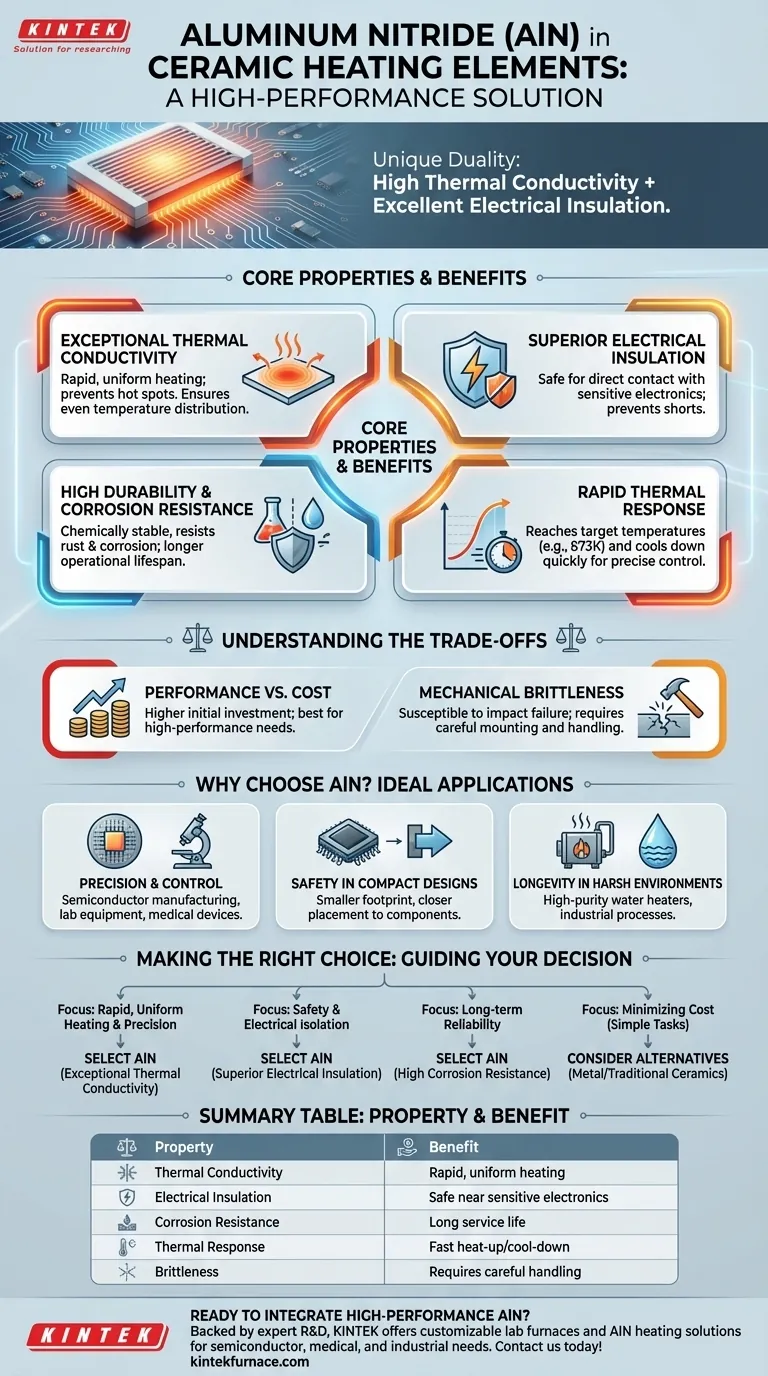

When evaluating advanced heating elements, Aluminum Nitride (AlN) is defined by a unique combination of high-performance properties. Its primary characteristics are exceptionally high thermal conductivity paired with excellent electrical insulation, enabling rapid heating, uniform temperature distribution, and high corrosion resistance.

The core advantage of Aluminum Nitride in heating elements is its rare ability to conduct heat as effectively as some metals while remaining a superb electrical insulator. This duality makes it the material of choice for applications demanding high-performance, precision, and safety.

The Core Properties of AlN Heaters Explained

To understand the value of AlN, it's essential to analyze how each of its properties contributes to its overall performance in a heating application.

Exceptional Thermal Conductivity

Unlike most ceramics which are thermal insulators, AlN has a very high thermal conductivity.

This allows heat to spread quickly and evenly across the element's surface, preventing dangerous hot spots and ensuring uniform heating of the target object. This property is the primary reason for its rapid heat-up times.

Superior Electrical Insulation

While it moves heat efficiently, AlN is a strong electrical insulator.

This is a critical safety and design feature. It prevents short circuits and allows the heating element to be placed in direct contact with sensitive electronic components without risk of electrical interference or damage.

High Durability and Corrosion Resistance

AlN is a chemically stable and hard material.

This inherent durability means it does not rust or corrode easily, leading to a significantly longer operational lifespan, especially in applications involving moisture or chemical exposure.

Rapid Thermal Response

The combination of high thermal conductivity and its ability to be formed into compact elements gives AlN a very fast response time.

It can reach target temperatures, such as 873K (600°C), very quickly and also cool down rapidly. This is crucial for processes requiring precise and dynamic temperature control.

Understanding the Trade-offs

No material is perfect for every situation. While AlN offers elite performance, it comes with considerations that are important for making a balanced decision.

Performance vs. Cost

Advanced ceramic materials like AlN typically involve more complex and costly manufacturing processes compared to traditional metal-sheathed heating elements.

The superior performance, efficiency, and longevity of AlN must be weighed against the higher initial investment. It is best suited for applications where its specific benefits are a necessity.

Mechanical Brittleness

Like most ceramics, AlN is harder but more brittle than metals.

This means it is more susceptible to failure from mechanical shock or impact. Careful design considerations regarding mounting and physical protection are necessary to ensure reliability.

Why Choose AlN for Your Application?

The decision to use an AlN ceramic heater is driven by specific application requirements where standard heaters fall short.

For Precision and Control

The rapid thermal response and even heat distribution make AlN ideal for semiconductor manufacturing, laboratory equipment, and medical devices where exact temperature profiles are non-negotiable.

For Safety in Compact Designs

Its excellent electrical insulation allows for smaller, more integrated designs. The heater can be placed closer to or in direct contact with the component it's heating, improving efficiency and shrinking the overall product footprint.

For Longevity in Demanding Environments

In applications like high-purity water heaters or industrial process heaters, AlN's resistance to corrosion ensures a longer service life and reduces maintenance needs compared to metal alternatives.

Making the Right Choice for Your Application

Your final decision should be guided by the most critical requirements of your project.

- If your primary focus is rapid, uniform heating and precision control: AlN is the ideal choice due to its exceptional thermal conductivity.

- If your primary focus is safety and electrical isolation: AlN's properties as an electrical insulator are superior for applications where the heater is near sensitive electronics.

- If your primary focus is long-term reliability in harsh conditions: The inherent durability and corrosion resistance of AlN ensure a long operational lifespan.

- If your primary focus is minimizing cost for a simple heating task: A traditional metal or a less advanced ceramic heater might be a more practical solution.

By understanding these core properties, you can confidently specify Aluminum Nitride for applications where performance and reliability cannot be compromised.

Summary Table:

| Property | Benefit for Heating Elements |

|---|---|

| Exceptional Thermal Conductivity | Rapid, uniform heating; prevents hot spots |

| Superior Electrical Insulation | Safe for use near sensitive electronics |

| High Corrosion Resistance | Long service life in harsh environments |

| Rapid Thermal Response | Fast heat-up and cool-down for precise control |

| Mechanical Brittleness | Requires careful handling and mounting |

Ready to integrate high-performance AlN ceramic heating into your application?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our AlN heating solutions deliver the precision, safety, and durability required for semiconductor manufacturing, medical devices, and demanding industrial processes.

Contact us today to discuss how our custom heating elements can enhance your project's performance and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance