In essence, W-Type Silicon Carbide (SiC) heating elements are primarily used in the large-scale production of float glass. Their unique W-shaped construction is specifically engineered to provide exceptionally uniform heat across wide, horizontal surfaces, a critical requirement in glass manufacturing and certain high-precision chemical and electronics processes.

The core value of a W-Type element is its specialized design. Its shape and three-phase power compatibility are not general features, but are purpose-built to solve the challenge of maintaining precise, even temperatures over a large, flat industrial process line.

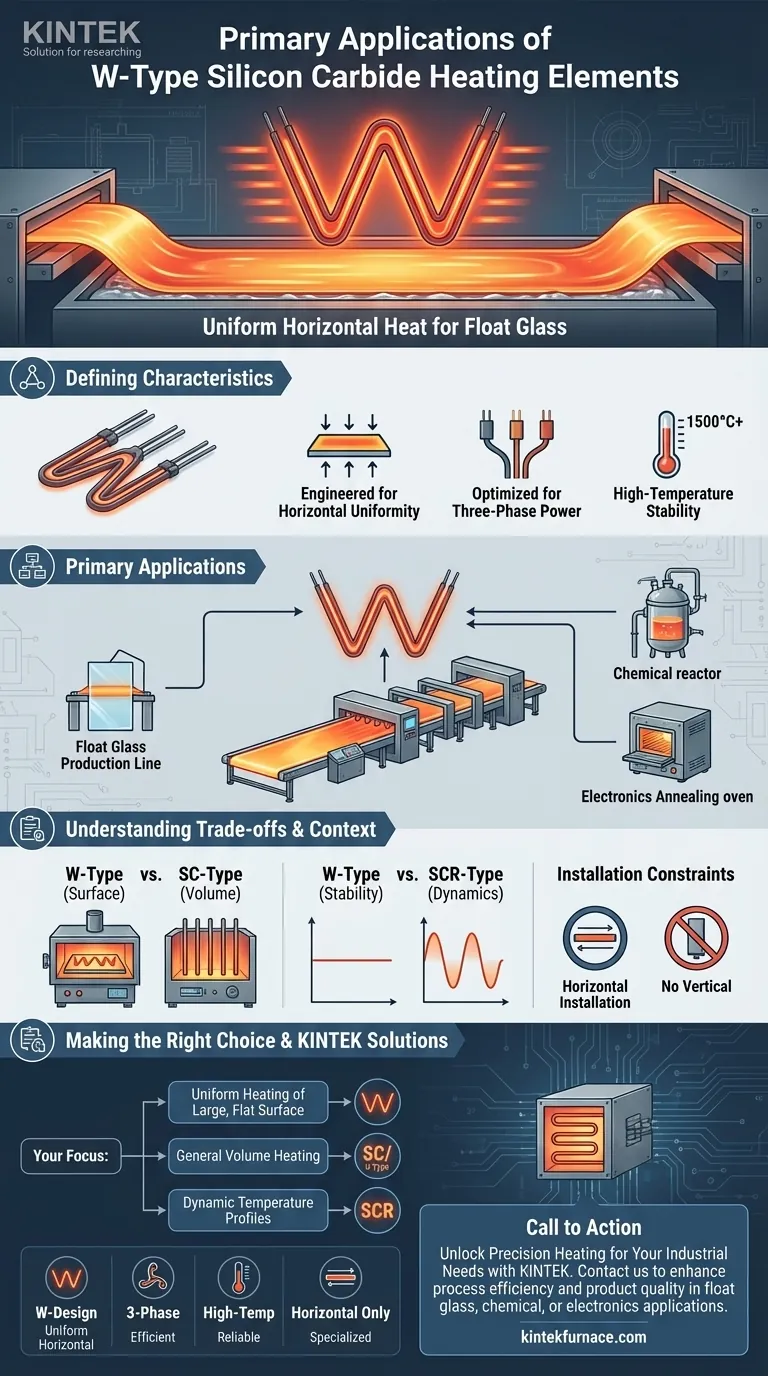

The Defining Characteristics of W-Type Elements

W-Type SiC elements possess a unique set of structural and electrical properties that dictate their ideal use cases. Understanding these characteristics reveals why they are chosen for such specific, high-stakes applications.

Engineered for Horizontal Uniformity

A W-Type element consists of three high-purity SiC heating rods connected at one end, forming a distinct "W" shape.

This design is intended exclusively for horizontal installation. It allows the element to create a broad, consistent thermal field over a large surface area, minimizing temperature differences and preventing hot or cold spots.

Optimized for Three-Phase Power

One of the most significant operational advantages is the ability to connect the W-Type element directly to a three-phase power supply.

For high-power industrial applications, this simplifies wiring, balances the electrical load on the facility's grid, and enhances overall operational efficiency compared to configuring multiple single-phase elements.

Unwavering High-Temperature Stability

Like all SiC elements, the W-Type is hard, brittle, and highly resistant to thermal shock and deformation at extreme temperatures. This physical robustness ensures reliability and high-temperature control accuracy over long operational campaigns.

Primary Applications in Detail

The design of the W-Type element makes it a specialist tool rather than a general-purpose heater. Its applications are few but critical.

The Keystone of Float Glass Manufacturing

The quintessential application for W-Type elements is in the float glass process. Here, a continuous ribbon of molten glass floats on a bath of molten tin, which can be hundreds of meters long and several meters wide.

Maintaining a perfectly uniform temperature across this entire surface is paramount to producing defect-free glass. The W-Type's ability to deliver consistent, horizontal heat makes it the ideal technology for this demanding environment.

Specialized Chemical and Electronics Processes

Beyond glass, these elements are used in other industrial processes that share similar requirements. This includes certain types of chemical reactors or large-scale annealing ovens for electronic substrates where uniform heating over a flat surface is essential for product quality.

Understanding the Trade-offs and Context

Choosing a W-Type element means prioritizing its specific strengths. It is not a universal solution, and its advantages become clear when compared to other SiC heater types.

W-Type vs. SC-Type: Surface vs. Volume

SC-Type (straight rod) elements are often used for the bottom or side heating of large furnaces, such as those in metal heat treatment or ceramics. Their purpose is to heat a large volume within an enclosure.

In contrast, the W-Type is designed to heat a large surface area in a process line. It excels at planar heating, not volumetric heating.

W-Type vs. SCR-Type: Stability vs. Dynamics

SCR-Type elements are often chosen for applications needing sophisticated thermal management and automated temperature adjustments, like in aerospace or advanced semiconductor manufacturing.

The W-Type's strength is maintaining a highly stable and uniform, but relatively static, temperature field. It is less suited for processes requiring rapid and complex temperature cycling.

Installation and Physical Constraints

The design dictates its limitation: the W-Type is built for horizontal installation only. It cannot be installed vertically or configured in complex geometric arrays, restricting its use to specific furnace designs. Its inherent brittleness also requires careful handling during installation and maintenance.

Making the Right Choice for Your Application

Selecting the correct heating element requires matching its core design strengths to the primary goal of your thermal process.

- If your primary focus is uniform heating of a large, flat, horizontal surface: The W-Type element is specifically engineered for this task and is likely your optimal choice.

- If your primary focus is heating the general volume of a large box furnace: An SC-Type or U-Type element designed for volumetric heating is a more appropriate solution.

- If your primary focus is a process with dynamic, rapidly changing temperature profiles: An SCR-Type element paired with an advanced controller will provide the necessary responsiveness.

Ultimately, choosing the right SiC element is about aligning the component's engineering with your specific industrial objective.

Summary Table:

| Characteristic | Benefit | Ideal Application |

|---|---|---|

| W-shaped design | Uniform horizontal heating | Float glass production |

| Three-phase power compatibility | Efficient, balanced electrical load | Large-scale industrial processes |

| High-temperature stability | Reliable, precise temperature control | Chemical reactors, electronics annealing |

| Horizontal installation only | Optimized for flat surface heating | Specialized furnace designs |

Unlock Precision Heating for Your Industrial Needs with KINTEK

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories and industrial settings. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

If you're involved in float glass manufacturing, chemical processing, or electronics annealing and need reliable, uniform heating solutions, our W-Type Silicon Carbide Heating Elements could be the perfect fit. Contact us today to discuss how we can enhance your process efficiency and product quality!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance