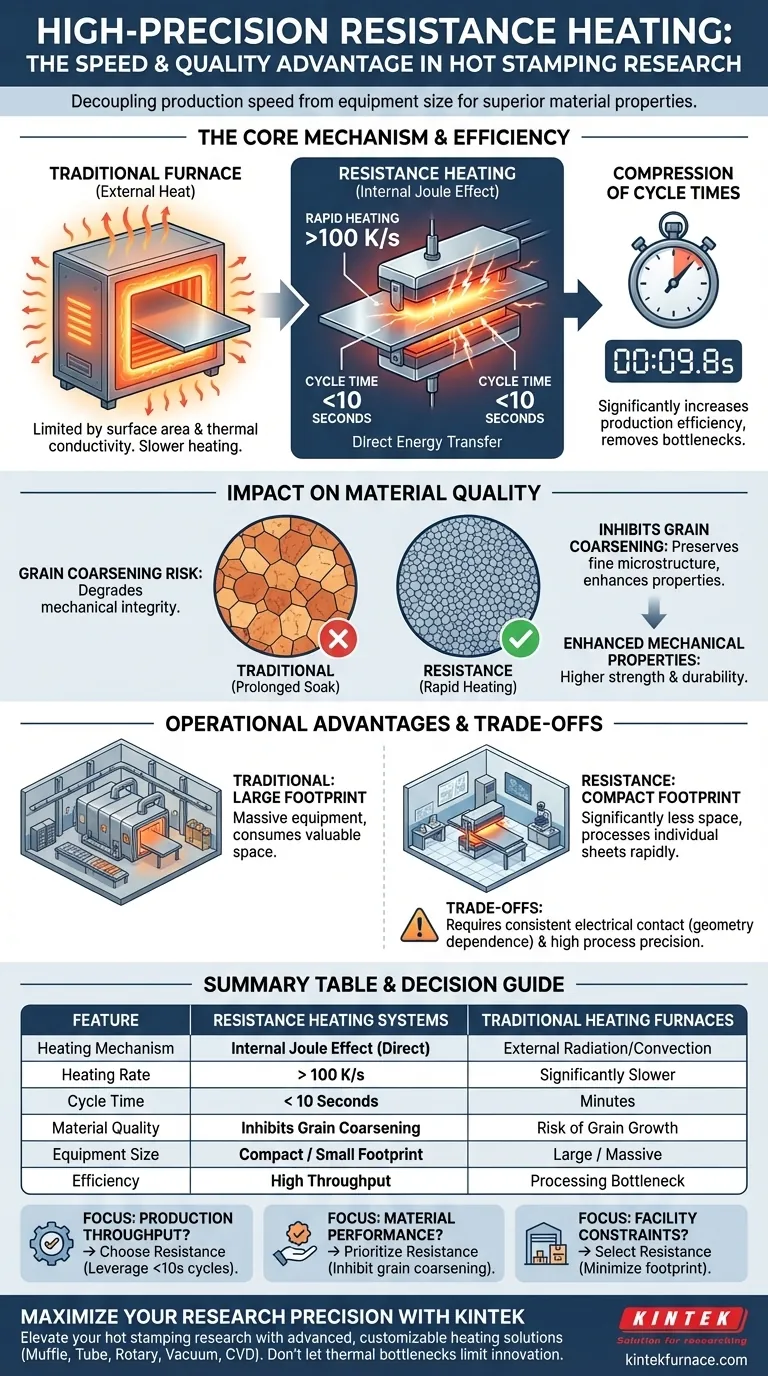

High-precision resistance heating systems offer a distinct performance advantage over traditional furnaces by utilizing Joule heating to pass high electrical current directly through the metal sheet. This direct energy transfer enables heating rates exceeding 100 K/s, allowing the complete heating process to finish in under 10 seconds, drastically outperforming the slower thermal transfer mechanisms of conventional radiation or convection furnaces.

Core Takeaway By shifting from external heat sources to internal resistance heating, these systems decouple production speed from equipment size. The result is a process that is not only faster and more compact but also produces superior material properties by strictly limiting the time available for microstructural degradation.

The Efficiency of Direct Energy Transfer

Rapid Heating via Joule Effect

Traditional furnaces rely on heat transferring from the environment to the material, a process limited by surface area and thermal conductivity.

Resistance systems bypass this by using the Joule effect, generating heat internally within the metal sheet itself.

This mechanism achieves aggressive heating rates of over 100 K/s, ensuring the target temperature is reached almost instantly.

Compression of Cycle Times

The ability to complete the heating phase in less than 10 seconds fundamentally changes the production rhythm.

In high-volume hot stamping, the heating phase is often the bottleneck; reducing this to seconds significantly increases overall production efficiency.

This allows for higher throughput without the need to maintain large banks of idle furnaces.

Impact on Material Quality

Inhibiting Grain Coarsening

Prolonged exposure to high temperatures is the primary cause of grain coarsening, which degrades the metal's mechanical integrity.

Because resistance heating is so rapid, the material spends minimal time at critical temperatures before forming.

This speed inhibits grain coarsening, preserving a finer microstructure.

Enhancing Mechanical Properties

The direct result of controlled grain structure is an improvement in the final mechanical properties of the hot-stamped component.

By minimizing the thermal history of the sheet, engineers can ensure the final part retains higher strength and durability compared to parts soaked in traditional furnaces.

Operational Advantages

Reducing Physical Footprint

Traditional furnaces are often massive to accommodate the residence time required for heating multiple sheets simultaneously.

High-precision resistance systems require significantly less space because they process individual sheets rapidly.

This reduction in equipment footprint frees up valuable floor space in research labs and manufacturing facilities.

Understanding the Trade-offs

Geometry and Contact Dependence

While not explicitly detailed in the reference, the reliance on passing current through the sheet implies a need for consistent electrical contact.

Unlike a batch furnace which heats whatever is inside, resistance heating requires specific electrode setups for different sheet geometries.

Process Control Sensitivity

With heating rates exceeding 100 K/s, the window for error is infinitesimal compared to slow-heating furnaces.

System precision is paramount; a deviation of mere seconds can drastically alter the temperature profile and material properties.

Making the Right Choice for Your Goal

When evaluating heating technologies for hot stamping research or production, align the method with your primary constraints.

- If your primary focus is Production Throughput: Choose resistance heating to leverage the <10 second cycle times and remove thermal bottlenecks.

- If your primary focus is Material Performance: Prioritize resistance heating to inhibit grain coarsening and maximize mechanical strength.

- If your primary focus is Facility Constraints: Select resistance heating to minimize equipment footprint and maximize floor space utilization.

High-precision resistance heating transforms the heating phase from a passive wait time into an active, quality-enhancing process step.

Summary Table:

| Feature | Resistance Heating Systems | Traditional Heating Furnaces |

|---|---|---|

| Heating Mechanism | Internal Joule Effect (Direct) | External Radiation/Convection |

| Heating Rate | > 100 K/s | Significantly Slower |

| Cycle Time | < 10 Seconds | Minutes |

| Material Quality | Inhibits Grain Coarsening | Risk of Grain Growth |

| Equipment Size | Compact / Small Footprint | Large / Massive |

| Efficiency | High Throughput | Processing Bottleneck |

Maximize Your Research Precision with KINTEK

Elevate your hot stamping and material science research with KINTEK’s advanced heating solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temp lab furnaces—all fully customizable to meet your unique performance requirements.

Don't let thermal bottlenecks limit your innovation. Contact us today to discover how our high-precision systems can optimize your material properties and streamline your production efficiency.

Visual Guide

References

- Bernd‐Arno Behrens, Lorenz Albracht. Increasing the performance of hot forming parts by resistance heating in XHV-adequate atmosphere. DOI: 10.1051/matecconf/202540801025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How do MoSi2 heating elements resist oxidation? Unlock the Secret to High-Temperature Durability

- What are the typical applications of SC Type Silicon Carbide Heating Elements? Ensure Uniform Heat for Industrial Processes

- What types of joints are recommended for connecting heating element sections? Choose Welded Joints for Reliability

- What factors contribute to the long lifespan of graphite heating elements? Maximize Your High-Temp Furnace Performance

- How does hydrogen affect SiC resistors? Understand the degradation risks and solutions

- What is the function of an IGBT transistor heating power supply in the induction heating evaporation process for magnesium powder? Unlock Precision Control for Superior Powder Quality

- What are the common types and corresponding working temperatures for MoSi2 heating elements? Choose the Right Element for Your Process

- What are the advantages of nickel alloys? Achieve Unmatched Performance in Extreme Environments