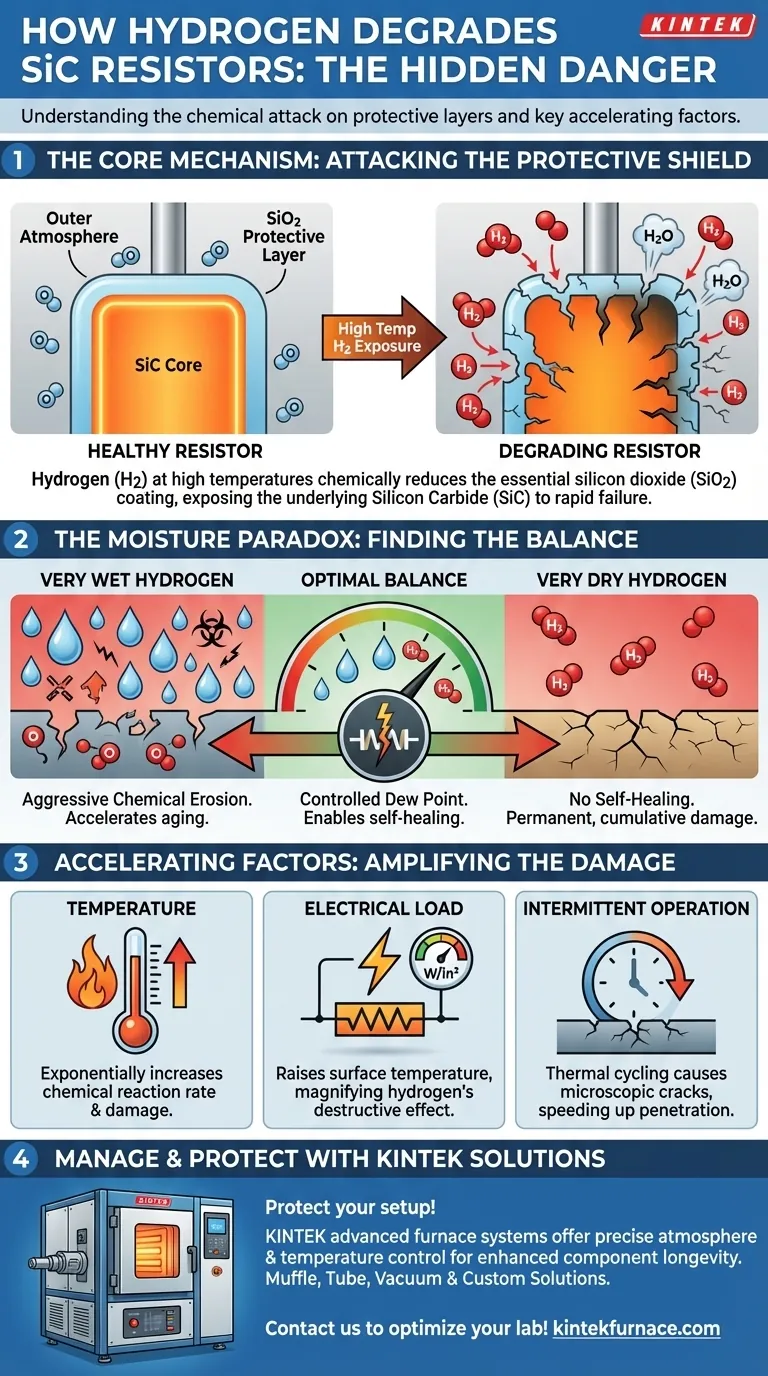

At its core, hydrogen degrades Silicon Carbide (SiC) resistors by chemically attacking their protective outer layer. This layer, a form of silicon dioxide (SiO2), is essential for the resistor's stability and long-term performance. When hydrogen reduces this coating, it exposes the underlying SiC material, causing its electrical properties to change and ultimately leading to premature failure.

The central challenge is not simply the presence of hydrogen, but managing the delicate balance of the resistor's protective oxide layer. Both very dry and very wet hydrogen atmospheres disrupt this balance, accelerating component aging and leading to unpredictable performance.

The Core Mechanism: Attacking the Protective Layer

To understand the risk, you must first understand that a SiC resistor's durability doesn't come from the silicon carbide alone. It relies heavily on a thin, glass-like coating of silicon dioxide.

The Role of the Silicon Dioxide (SiO2) Coating

This SiO2 layer acts as a chemical shield, protecting the core SiC element from the surrounding atmosphere, especially at the high operating temperatures where these components excel. Without this passive, protective film, the resistor is vulnerable to oxidation and chemical attack.

How Hydrogen Reduces the Coating

At elevated temperatures, hydrogen gas (H2) is a reducing agent. It actively reacts with the silicon dioxide (SiO2) shield, stripping away oxygen atoms to form water vapor (H2O) and other volatile silicon-oxygen compounds. This chemical reaction effectively erodes the resistor's armor.

The Consequence: Resistor Deterioration

Once the SiO2 layer is compromised or removed, the resistor's performance begins to degrade. Its resistance value can drift significantly, and the underlying SiC material becomes susceptible to further, more rapid degradation. This leads to unreliable operation and eventual component failure.

The Critical Influence of Moisture

Counterintuitively, the moisture content within the hydrogen atmosphere is a critical factor in the rate of decay. Both extremes—very wet and very dry—are detrimental.

The Danger of "Very Wet" Hydrogen

A high concentration of water vapor in the hydrogen atmosphere can create a more aggressive chemical environment. This can accelerate the erosion of the SiO2 layer and attack the SiC material itself, speeding up the aging process.

The Surprising Danger of "Very Dry" Hydrogen

This is a common pitfall. In a completely dry hydrogen atmosphere, the protective SiO2 layer has no way to "self-heal." Under normal conditions, trace amounts of oxidizing agents (like water vapor) help maintain the oxide layer. Without them, any reduction of the layer by hydrogen is permanent and cumulative, leading to a slow but certain death of the component.

Understanding the Trade-offs and Broader Context

Hydrogen is a significant factor, but resistor aging is a multi-faceted problem. The damage caused by hydrogen is often amplified by other operational stresses.

The Accelerating Effect of Temperature

The chemical reaction rate between hydrogen and silicon dioxide is highly dependent on temperature. As the operating temperature of the resistor increases, the rate of degradation caused by hydrogen exposure increases exponentially.

The Impact of Electrical Loading

A higher electrical load (measured in watts per square inch) directly translates to a higher surface temperature on the resistor. This localized heating magnifies the destructive effect of the hydrogen atmosphere, even if the ambient temperature is moderate.

Continuous vs. Intermittent Operation

Intermittent operation introduces thermal cycling, which can cause microscopic cracks to form in the protective SiO2 layer. These cracks create new pathways for hydrogen to penetrate and attack the resistor, potentially causing faster failure than in a continuous-duty application at the same peak temperature.

Making the Right Choice for Your Application

To ensure system reliability, you must move beyond simply knowing that hydrogen is harmful and begin managing the specific conditions that accelerate damage.

- If your primary focus is maximizing resistor lifespan: You must actively control the moisture content in your hydrogen atmosphere, aiming for a stable dew point rather than simply assuming "drier is better."

- If you are operating at high temperatures: Recognize that temperature is a powerful accelerant; the damaging effects of hydrogen increase dramatically with heat, requiring much stricter atmospheric control and potentially component de-rating.

- If you cannot control the atmosphere: You must accept a shorter component life and budget for a proactive maintenance and replacement schedule based on testing in your specific environment.

By understanding that resistor health depends on the stability of its protective oxide layer, you can move from reacting to failures to proactively managing component longevity.

Summary Table:

| Factor | Effect on SiC Resistor |

|---|---|

| Hydrogen Exposure | Reduces SiO2 protective layer, leading to resistance drift and failure |

| Moisture Level | Both very wet and very dry hydrogen accelerate degradation |

| Temperature | Higher temperatures exponentially increase hydrogen-induced damage |

| Electrical Load | Increases surface temperature, magnifying hydrogen effects |

| Operation Type | Intermittent use causes thermal cycling and cracks, speeding failure |

Protect your SiC resistors from hydrogen damage with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing reliability and longevity. Contact us today to discuss how we can optimize your setup!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating