At its core, the SC Type Silicon Carbide (SiC) heating element is the standard choice for large-scale industrial furnaces where temperature uniformity is critical. Its design is fundamentally geared towards providing consistent, even heat across large surfaces, making it indispensable in industries like metal heat treatment, ceramics, glass production, and semiconductor manufacturing.

The decision to use an SC Type element is driven by the need for process consistency. Its single spiral design is engineered specifically to eliminate hot spots and temperature variations, ensuring that materials processed in bulk receive the same uniform thermal treatment.

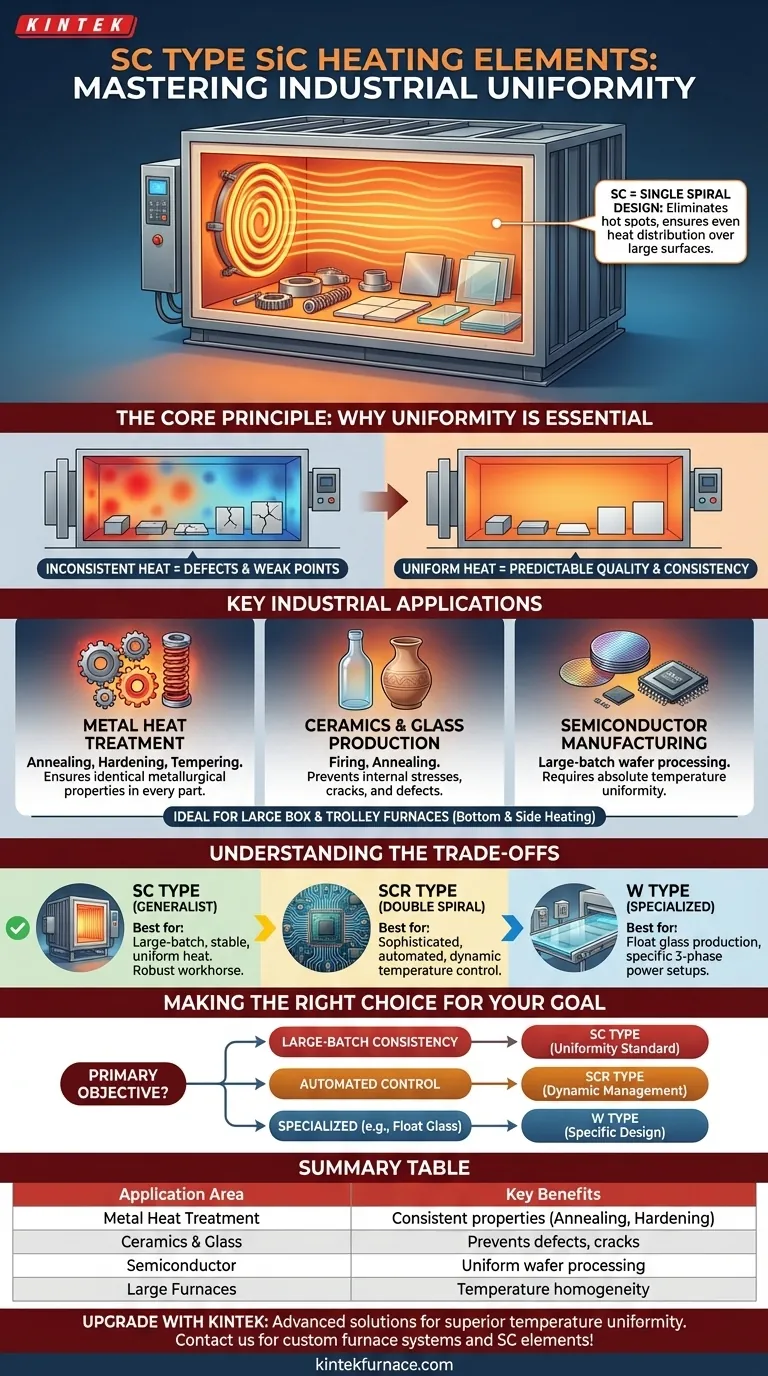

The Core Principle: Why Uniformity is Essential

The value of the SC Type element is not just in its ability to generate high temperatures, but in its ability to distribute that heat evenly. This characteristic is a direct result of its physical design and material properties.

The Single Spiral (SC) Design

The "SC" designation stands for Single Spiral. This refers to the specific physical configuration of the silicon carbide element.

This spiral design acts as a large, uniform radiating surface. Its ceramic construction provides high electrical resistance, which generates heat efficiently and ensures that heat is distributed evenly across the element's entire length.

The Impact on Process Quality

In many industrial processes, a small temperature variance can ruin an entire batch. Uniform heating is not a luxury; it is a requirement for predictable and repeatable quality.

For example, in metal heat treatment processes like annealing or tempering, inconsistent heating results in inconsistent metallurgical properties. This can lead to weak points, brittleness, or other material failures.

Ideal for Large Furnace Architectures

The SC Type's design is particularly effective for bottom or side heating configurations in large industrial equipment.

This includes large box furnaces and trolley furnaces, where the primary engineering challenge is maintaining a stable and homogenous temperature throughout a massive internal volume.

Key Industrial Applications in Detail

The SC Type's ability to deliver uniform heat makes it a workhorse in several key industries.

Metal Heat Treatment

This is a primary application. SC elements provide the stable and precise thermal environment required for processes like annealing, hardening, tempering, and carburizing. The goal is to ensure every part in the furnace achieves the exact same material properties.

Ceramics and Glass Production

During the firing of ceramics or the annealing of glass, even heating is critical to prevent internal stresses, cracks, and defects. SC elements provide the large, stable thermal zones needed for these sensitive processes.

Semiconductor Manufacturing

While highly specialized processes may use other elements, the SC Type is used in foundational furnace steps for semiconductor production. This includes large-batch processes where wafer substrates must be heated with absolute uniformity to ensure consistent quality.

Understanding the Trade-offs

Choosing the right element means understanding what it's not optimized for. The SC Type is a powerful generalist for uniformity, but other types exist for more specialized needs.

SC Type vs. SCR Type

The SC Type is the go-to for stable, uniform heat in large-batch furnaces. It is a robust and reliable workhorse.

The SCR (Double Spiral) Type, by contrast, is often favored for more sophisticated thermal management. It is used in high-end applications like aerospace or advanced electronics manufacturing where automated, rapid, or complex temperature adjustments are required.

SC Type vs. W Type

The W Type is a highly specialized element. It is most commonly used in float glass production lines and certain chemical processes, often designed for a direct connection to a three-phase power supply. If you are not in these specific industries, the SC type is likely the more appropriate choice.

Limitations to Consider

The SC Type's strength is broad, even heating. It may not be the most efficient choice for applications requiring highly localized or rapidly cycling heat, where a different element geometry might offer better performance.

Making the Right Choice for Your Goal

Your application's primary objective will determine the correct heating element.

- If your primary focus is large-batch processing with consistent quality: The SC Type is your standard choice for its exceptional temperature uniformity over large areas.

- If your primary focus is sophisticated, automated temperature control: You should evaluate SCR Type elements for their superior performance in dynamic thermal management.

- If your primary focus is a specialized application like float glass manufacturing: The W Type element is specifically designed for these environments and power configurations.

Selecting the right heating element is about matching its core design principle to your specific process objective.

Summary Table:

| Application Area | Key Benefits |

|---|---|

| Metal Heat Treatment | Ensures consistent metallurgical properties in annealing, hardening, tempering |

| Ceramics and Glass Production | Prevents defects and cracks with stable, even heating |

| Semiconductor Manufacturing | Provides uniform thermal treatment for large-batch wafer processing |

| Large Industrial Furnaces | Delivers temperature homogeneity in box and trolley furnaces |

Upgrade your industrial processes with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique needs, such as achieving superior temperature uniformity in metal heat treatment or ceramics production. Contact us today to discuss how our SC Type SiC heating elements can enhance your efficiency and quality!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan