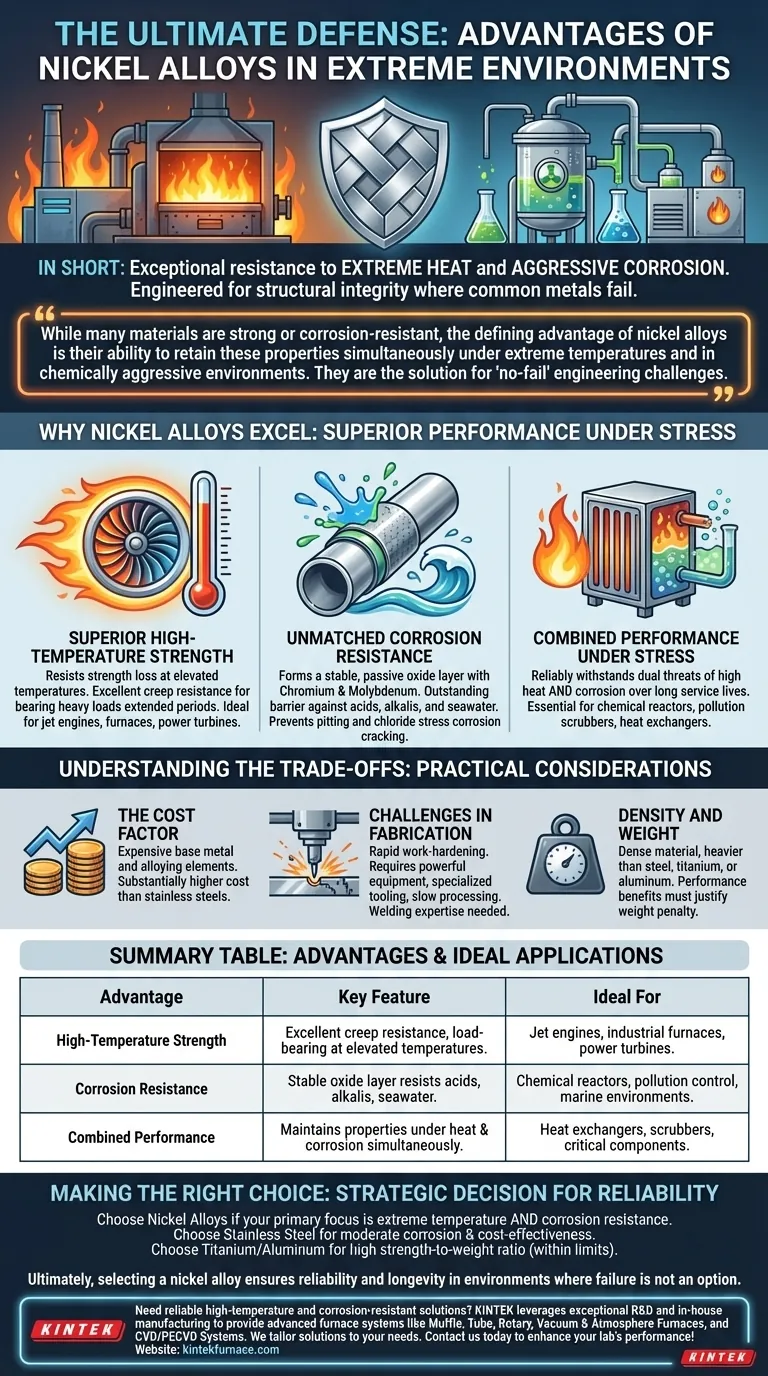

In short, the primary advantages of nickel alloys are their exceptional resistance to both extreme heat and aggressive corrosion. These materials are specifically engineered to maintain their structural integrity and performance in severe service conditions where common metals like steel or aluminum would quickly degrade and fail.

While many materials are strong or corrosion-resistant, the defining advantage of nickel alloys is their ability to retain these properties simultaneously under extreme temperatures and in chemically aggressive environments. They are the solution for "no-fail" engineering challenges.

Why Nickel Alloys Excel in Extreme Environments

The value of a nickel alloy is not just in one single attribute but in its combined performance under severe stress. This makes them indispensable in industries from aerospace to chemical processing.

Superior High-Temperature Strength

Most metals lose a significant amount of their strength as temperatures rise. Nickel alloys, however, are designed to resist this effect.

This property, known as high-temperature strength or creep resistance, means they can bear heavy loads for extended periods at elevated temperatures without deforming. This is critical for components inside jet engines, industrial furnaces, and power generation turbines.

Unmatched Corrosion Resistance

Nickel is inherently slow to oxidize. When alloyed with elements like chromium and molybdenum, it forms an extremely stable, passive oxide layer on its surface.

This layer acts as a barrier, providing outstanding resistance to a wide range of corrosive media, including acids, alkalis, and seawater. It's particularly effective at preventing pitting and chloride stress corrosion cracking, a common failure mode for many stainless steels.

Combined Performance Under Stress

The true advantage of nickel alloys becomes clear in applications involving both high heat and corrosion.

Environments like chemical reactors, pollution control scrubbers, and heat exchangers often subject materials to this dual threat. Nickel alloys are one of the few material classes that can reliably withstand these combined forces over long service lives.

Understanding the Trade-offs

While their performance is exceptional, nickel alloys are a specialized solution. Their advantages come with practical considerations that must be weighed for any project.

The Cost Factor

Nickel is a relatively expensive base metal, and the other elements used in these superalloys (like chromium, molybdenum, and niobium) also add significant cost. As a result, nickel alloys are substantially more expensive than even high-grade stainless steels.

Challenges in Fabrication

The same properties that make nickel alloys strong and tough also make them difficult to work with.

They are known for work-hardening rapidly, which means machining requires powerful equipment, specialized tooling, and slower processing speeds. Welding also requires specific expertise and procedures to avoid cracking and maintain corrosion resistance in the heat-affected zone.

Density and Weight

Nickel alloys are dense materials, typically more so than steel and significantly heavier than titanium or aluminum alloys. In applications where weight is a primary concern, such as aerospace, the performance benefits must be substantial enough to justify the weight penalty.

Making the Right Choice for Your Application

The decision to use a nickel alloy should be driven by the specific demands of your operating environment.

- If your primary focus is extreme temperature and corrosion resistance: Nickel alloys are often the only viable choice, especially when both demanding conditions are present.

- If your primary focus is cost-effectiveness for a moderately corrosive environment: A high-grade stainless steel might offer a better balance of performance and price.

- If your primary focus is a high strength-to-weight ratio: Titanium or advanced aluminum alloys may be more suitable, provided the temperature and corrosion challenges are within their limits.

Ultimately, selecting a nickel alloy is a strategic decision to ensure reliability and longevity in environments where failure is not an option.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| High-Temperature Strength | Excellent creep resistance and load-bearing at elevated temperatures | Jet engines, industrial furnaces, power turbines |

| Corrosion Resistance | Stable oxide layer resists acids, alkalis, and seawater | Chemical reactors, pollution control systems, marine environments |

| Combined Performance | Maintains properties under heat and corrosion simultaneously | Heat exchangers, scrubbers, critical engineering components |

Need reliable high-temperature and corrosion-resistant solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor solutions to meet your unique experimental needs in aerospace, chemical processing, and more. Contact us today to enhance your lab's performance and durability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals