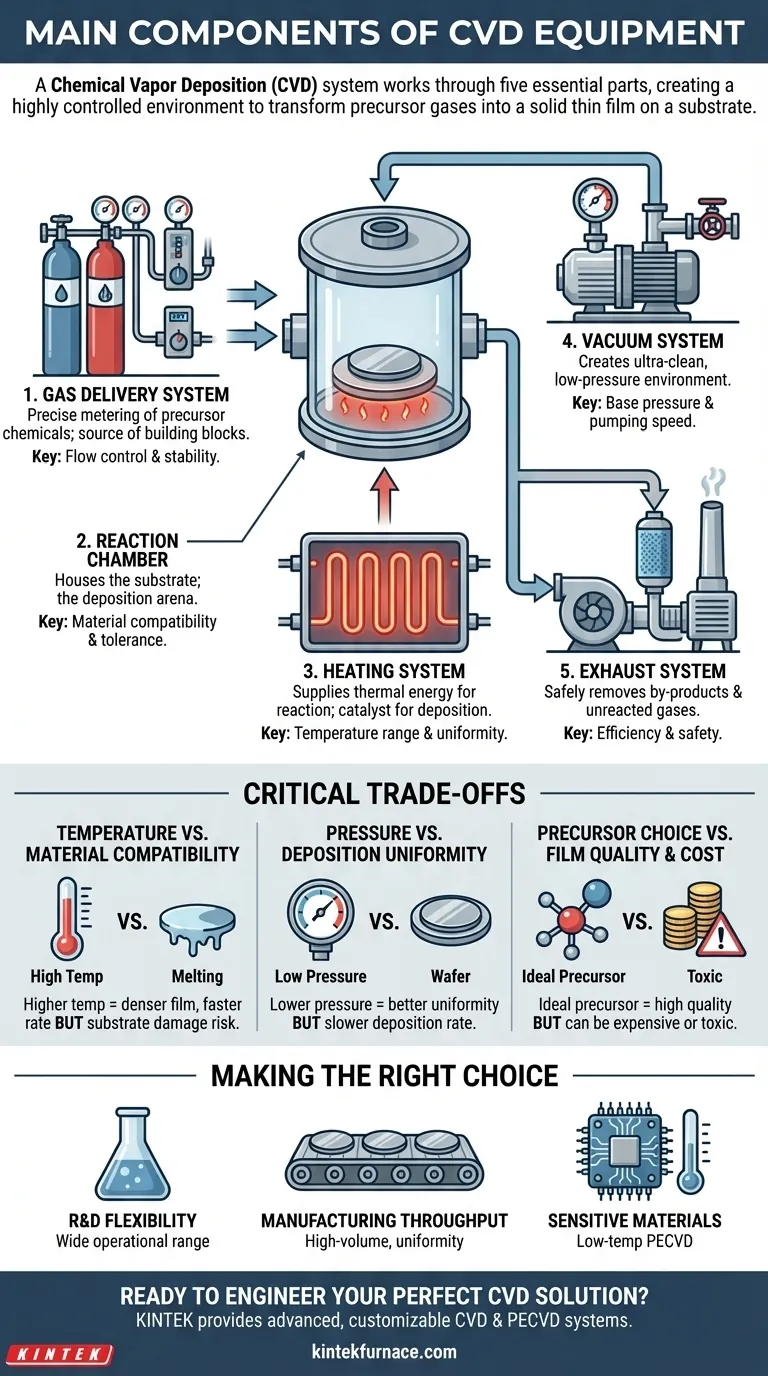

At its core, a Chemical Vapor Deposition (CVD) system is comprised of five essential parts that work in unison: a gas delivery system, a reaction chamber, an energy source for heating, a vacuum system, and an exhaust system. These components create a highly controlled environment to transform volatile chemical gases, known as precursors, into a solid, high-performance thin film on the surface of a material, called a substrate.

A CVD apparatus is not merely a collection of hardware. It is a precision instrument designed to control a chemical reaction on an atomic level, where each component plays a critical role in managing the journey of precursor molecules from a gas cylinder to a solid layer on a substrate.

How the Components Work in Concert

Understanding the function of each component reveals how the CVD process achieves its remarkable precision. The entire system is engineered to meticulously control the environment and the flow of materials to build a thin film, one layer of atoms or molecules at a time.

The Gas Delivery System: The Source of Building Blocks

The process begins with the precursors—specialty gases or vaporized liquids that contain the atoms needed for the final film.

The gas delivery system is responsible for storing these volatile chemicals and delivering them to the reaction chamber. It uses mass flow controllers to meter the flow of each gas with extreme precision, ensuring the chemical "recipe" is exact.

The Reaction Chamber: The Deposition Arena

The reaction chamber is a sealed, robust vessel that houses the substrate (the material to be coated). This is the heart of the system where the deposition takes place.

Chambers are designed to withstand high temperatures and vacuum conditions while ensuring a clean, inert environment, preventing contamination that could ruin the final film.

The Energy & Heating System: The Catalyst for Reaction

For the precursors to react and form a film, they need energy. In most CVD systems, this energy is supplied by a high-temperature furnace or heating elements that heat the substrate.

This thermal energy breaks the chemical bonds in the precursor molecules, allowing the desired atoms to deposit onto the hot substrate surface. Temperatures can range from 200°C to over 1500°C, depending on the specific process.

The Vacuum System: Creating the Clean Environment

CVD is performed under vacuum for two critical reasons. First, the vacuum pump removes air and other atmospheric contaminants from the chamber, creating an ultra-clean environment.

Second, operating at a pressure far below atmosphere ensures the precursor gas molecules can travel to the substrate surface with minimal collisions, promoting a more uniform and higher-quality film.

The Exhaust & Gas Management System: Ensuring Purity and Safety

As the chemical reaction occurs, it produces not only the desired film but also gaseous by-products.

The exhaust system, often including pumps and scrubbers, safely removes these by-products and any unreacted precursor gases from the chamber. This prevents them from interfering with the reaction and neutralizes potentially hazardous materials before they are vented.

Understanding the Critical Trade-offs

The performance of a CVD system is a constant balance of competing factors. Optimizing one parameter often requires a compromise in another, and understanding these trade-offs is key to mastering the process.

Temperature vs. Material Compatibility

Higher temperatures generally lead to denser, higher-purity films and faster deposition rates. However, the substrate must be able to withstand these temperatures without melting, warping, or being damaged. This is a primary constraint when choosing a deposition process.

Pressure vs. Deposition Uniformity

Lowering the pressure inside the chamber improves the mean free path of gas molecules, leading to better film uniformity across the entire substrate. The trade-off is that lower pressures can significantly slow down the rate of deposition, impacting manufacturing throughput.

Precursor Choice vs. Film Quality & Cost

The selection of the precursor chemical is fundamental. An ideal precursor is stable enough to be delivered but reactive enough at the desired temperature. However, the highest-performing precursors can be extremely expensive, toxic, or difficult to handle, creating a trade-off between film quality, process cost, and operational safety.

Making the Right Choice for Your Goal

The configuration of a CVD system is directly tied to its intended application. The ideal setup depends entirely on your primary objective.

- If your primary focus is research and development: You need a highly flexible system with a wide operational range for temperature, pressure, and gas chemistry to explore new materials and processes.

- If your primary focus is high-volume manufacturing: Your priority is a system optimized for throughput, repeatability, and exceptional uniformity, often with automated wafer handling.

- If your primary focus is coating sensitive materials (like plastics or certain electronics): You require a low-temperature variant like Plasma-Enhanced CVD (PECVD), which uses an RF energy source to supplement thermal energy.

By understanding how these core components function and interact, you gain the ability to control the deposition environment and, ultimately, engineer the properties of your final material.

Summary Table:

| Component | Primary Function | Key Consideration |

|---|---|---|

| Gas Delivery System | Precise metering and delivery of precursor chemicals. | Flow control accuracy and precursor stability. |

| Reaction Chamber | Houses the substrate and provides a sealed environment for deposition. | Material compatibility and temperature/pressure tolerance. |

| Heating System | Supplies thermal energy to catalyze the chemical reaction. | Temperature range, uniformity, and heating rate. |

| Vacuum System | Creates a contaminant-free, low-pressure environment. | Base pressure level and pumping speed. |

| Exhaust System | Safely removes reaction by-products and unreacted gases. | Efficiency and safety (e.g., scrubbing hazardous gases). |

Ready to Engineer Your Perfect CVD Solution?

Understanding the components is the first step; integrating them into a system that meets your unique research or production goals is the next. KINTEK excels at this.

Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced CVD and PECVD systems. Our deep customization capability allows us to precisely tailor systems to your specific requirements, whether you need:

- R&D Flexibility: A system with a wide operational range for exploring new materials.

- Manufacturing Throughput: An optimized system for high-volume, uniform production.

- Low-Temperature Coating: A PECVD system for sensitive substrates.

Let's discuss how we can build a CVD system that delivers the precise film properties you need. Contact our experts today for a consultation.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition