In short, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a foundational technology for manufacturing advanced optical coatings. It enables the deposition of thin films with precisely engineered optical properties—such as a specific refractive index—onto a wide variety of materials, including those that cannot withstand high heat. This control makes it essential for creating products like anti-reflective lenses, specialized mirrors, and optical filters.

The true advantage of PECVD in optics is not just its ability to deposit a coating, but its power to do so at low temperatures. This unlocks the use of high-performance optical coatings on heat-sensitive materials like plastics and allows for uniform coverage on complex, non-flat surfaces.

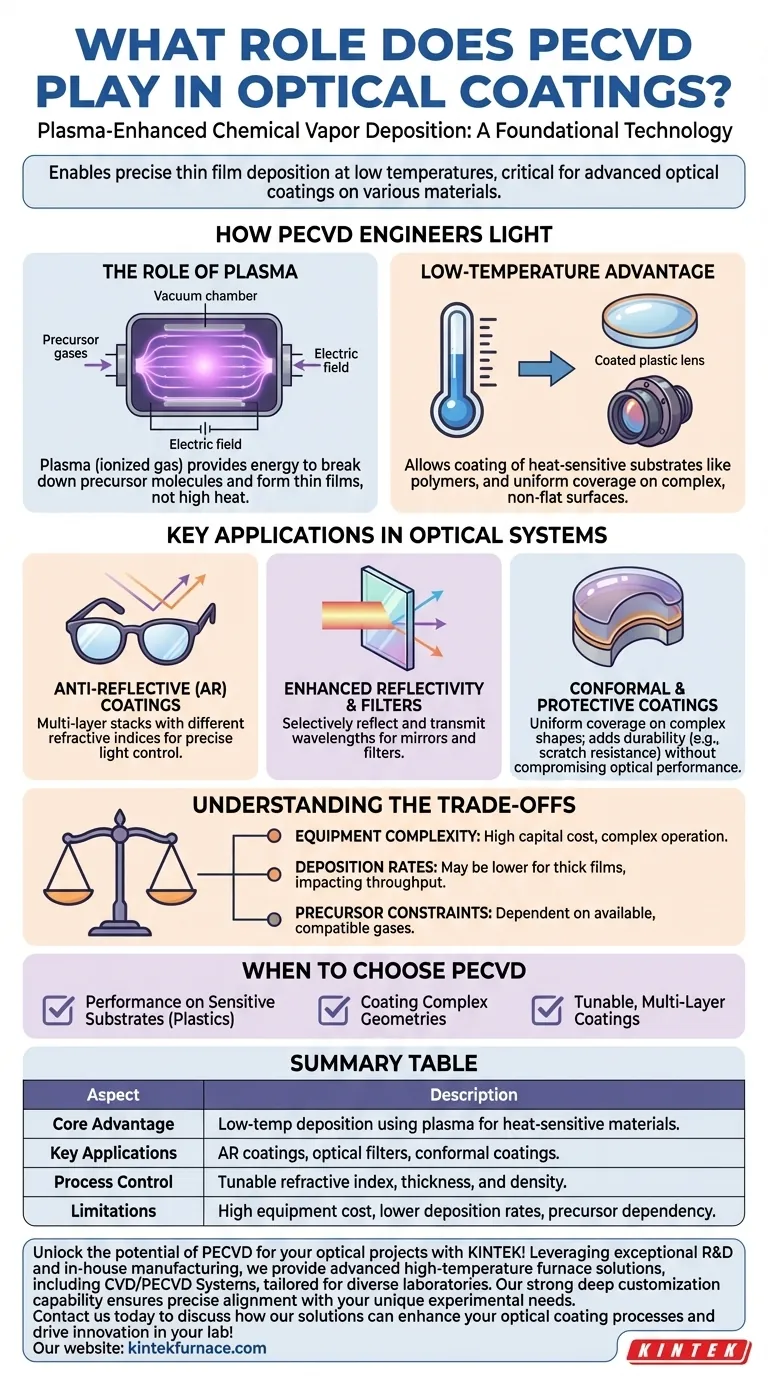

How PECVD Engineers Light

The effectiveness of PECVD stems from its unique method of energizing the deposition process. Unlike traditional Chemical Vapor Deposition (CVD), which relies on high temperatures, PECVD uses plasma.

The Role of Plasma

The process takes place in a vacuum chamber where precursor gases are introduced. An electric field is applied, exciting the gas into a plasma—an ionized state of matter.

This plasma contains highly reactive ions and radicals. It provides the necessary energy to break down the precursor molecules and drive the chemical reactions that form the thin film on the substrate's surface.

The Low-Temperature Advantage

Because the plasma provides the energy, the substrate itself does not need to be heated to extreme temperatures. This is the single most important advantage for many optical applications.

This allows for the successful coating of temperature-sensitive substrates like polymers (plastics), assembled optical components, and other materials that would be damaged or destroyed by high-temperature deposition methods.

Precision Through Process Control

The final properties of the optical coating are directly tied to the process parameters. By meticulously controlling the gas composition, pressure, temperature, and plasma power, engineers can precisely tune the film's characteristics.

Most critically, this allows for the fine-tuning of the refractive index, density, and thickness of the film, which are the fundamental variables used to control how light reflects from or transmits through a surface.

Key Applications in Optical Systems

PECVD's control and low-temperature processing enable a range of critical optical applications.

Anti-Reflective (AR) Coatings

AR coatings reduce unwanted reflections from surfaces like eyeglass lenses and camera optics. They typically consist of multiple layers, each with a different refractive index and thickness.

PECVD is ideal for creating these complex multi-layer stacks, as it allows for the precise, sequential deposition of different materials to achieve the desired destructive interference of light waves.

Enhanced Reflectivity and Filters

The same principle of layering materials with different refractive indices can be used to create highly reflective coatings for mirrors or specialized optical filters.

These filters, known as dichroic filters, are designed to selectively reflect certain wavelengths of light while transmitting others, a capability essential in devices like photometers and projection systems.

Conformal and Protective Coatings

PECVD provides excellent conformal coverage, meaning it can deposit a uniform film over parts with complex or irregular shapes, such as curved lenses or intricate optical sensors.

Furthermore, it can be used to deposit hard, durable materials like silicon nitride. These films add scratch resistance and environmental protection to delicate optical surfaces without compromising their optical performance.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. An objective assessment requires understanding its limitations.

Equipment and Process Complexity

PECVD systems are complex vacuum chambers that require significant capital investment and expertise to operate and maintain. The process itself can be sensitive to contamination and requires careful calibration.

Deposition Rates

While effective, PECVD can have lower deposition rates compared to some other methods like sputtering. For applications requiring very thick films, this can lead to longer processing times, impacting throughput and cost.

Precursor Material Constraints

The process is dependent on the availability of suitable precursor gases that can be effectively dissociated in a plasma to form the desired film. The chemistry must be compatible with the plasma environment, and precursor purity is critical to the quality of the final optical coating.

When to Choose PECVD for Your Optical Project

Your choice of deposition technology depends entirely on your project's specific constraints and performance goals.

- If your primary focus is performance on sensitive substrates: PECVD is the definitive choice for coating plastics, polymers, or pre-assembled components that cannot tolerate high heat.

- If your primary focus is coating complex geometries: The conformal nature of PECVD makes it superior for achieving uniform coatings on curved lenses, structured optics, or other non-flat surfaces.

- If your primary focus is tunable, multi-layer coatings: PECVD provides the layer-by-layer control over refractive index and thickness required for high-performance AR coatings and advanced optical filters.

By understanding its core mechanism and trade-offs, you can confidently determine if PECVD is the right tool to achieve your specific optical goals.

Summary Table:

| Aspect | Description |

|---|---|

| Core Advantage | Low-temperature deposition using plasma, enabling coating of heat-sensitive materials like plastics. |

| Key Applications | Anti-reflective coatings, optical filters, conformal coatings on complex shapes. |

| Process Control | Tunable refractive index, thickness, and density through gas, pressure, and plasma power adjustments. |

| Limitations | High equipment cost, lower deposition rates, and dependency on precursor gases. |

Unlock the potential of PECVD for your optical projects with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions, including CVD/PECVD Systems, tailored for diverse laboratories. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're developing anti-reflective coatings, optical filters, or coatings on heat-sensitive materials. Contact us today to discuss how our solutions can enhance your optical coating processes and drive innovation in your lab!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures