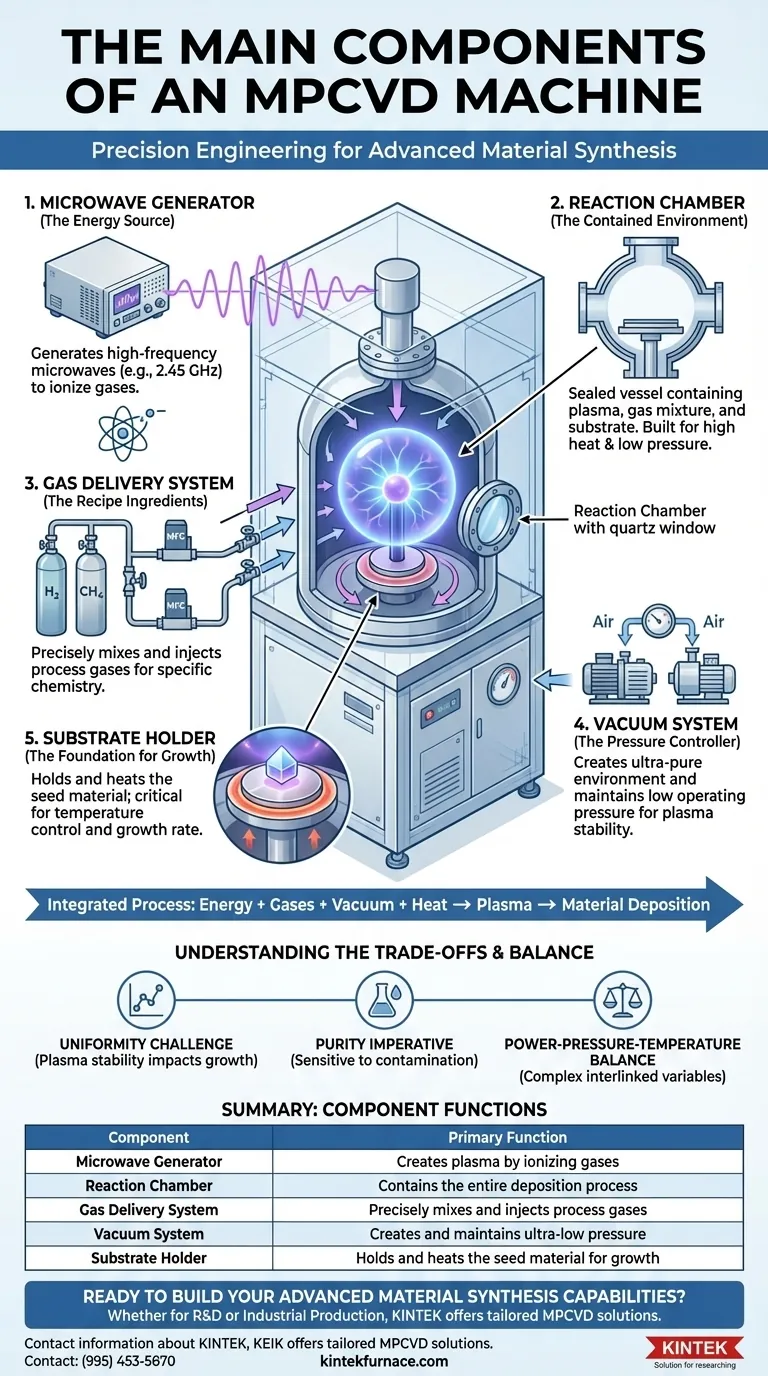

At its core, an MPCVD (Microwave Plasma Chemical Vapor Deposition) machine is a highly controlled environment designed for material synthesis. The main components are the microwave generator, a reaction chamber, a gas delivery system, a vacuum system, and a substrate holder. Together, these parts create the precise conditions of low pressure, high energy, and specific chemistry needed to grow high-purity materials like lab-grown diamonds and other advanced thin films.

An MPCVD system functions by using microwave energy to transform a specific gas mixture into a plasma, which contains reactive chemical species. These species then deposit onto a heated substrate, building up a new material layer by layer in a meticulously controlled vacuum environment.

The Core Components: A Functional Breakdown

To understand how an MPCVD system operates, it is essential to understand the specific role each core component plays in the deposition process. They are not independent parts but a deeply integrated system.

The Microwave Generator: The Energy Source

This is the engine of the system. It generates high-frequency microwaves, typically at 2.45 GHz, which are channeled into the reaction chamber.

This focused energy is what ionizes the process gases, stripping electrons from their atoms and creating the super-heated, chemically reactive state of matter known as plasma.

The Reaction Chamber: The Contained Environment

The reaction chamber is a sealed, durable vessel, often made of stainless steel with a quartz window, where the entire deposition process occurs.

It is designed to withstand both the intense heat of the plasma and the low pressure of the vacuum. This chamber contains the substrate, the gas mixture, and the plasma itself.

The Gas Delivery System: The Recipe Ingredients

This system is a network of pipes, valves, and mass flow controllers (MFCs) that precisely mix and inject gases into the reaction chamber.

For diamond growth, this typically involves a mixture of a carbon source gas (like methane, CH₄) and a large amount of hydrogen (H₂). The accuracy of this system directly dictates the purity and quality of the final material.

The Vacuum System: The Pressure Controller

The vacuum system, composed of one or more pumps, serves two critical functions. First, it purges the chamber of all atmospheric air to create an ultra-pure environment before the process begins.

Second, it maintains the extremely low operating pressure (typically a few hundred Torr) required for the plasma to form and remain stable. This control is non-negotiable for consistent deposition.

The Substrate Holder: The Foundation for Growth

This component holds the "seed" material, or substrate, on which the new material will grow. It is positioned directly within the plasma field.

Crucially, the holder is almost always connected to a temperature control system. Substrate temperature is a critical variable that influences the growth rate and crystal quality, making this more than just a simple platform.

Understanding the Trade-offs

While powerful, MPCVD technology is governed by a delicate balance of competing physical parameters. Understanding these challenges is key to appreciating the process.

The Challenge of Uniformity

Creating a large, perfectly uniform plasma ball is difficult. Any instability or "hot spot" in the plasma can lead to uneven growth across the substrate.

This directly impacts the size and quality of the usable material that can be produced in a single run, making chamber design and power delivery critical for scaling up production.

The Purity Imperative

The entire process is extremely sensitive to contamination. A microscopic leak in the vacuum system or impurities in the gas lines can introduce unwanted elements like nitrogen.

These contaminants disrupt the crystal lattice as it forms, leading to defects, discoloration, or complete failure of the growth process.

The Power, Pressure, and Temperature Balance

These three parameters are inextricably linked. Adjusting the microwave power changes the plasma's temperature and density, which in turn affects the optimal pressure and substrate temperature.

Mastering MPCVD involves finding a stable "process window" where all these variables are balanced perfectly to achieve the desired outcome. This is often a proprietary and hard-won piece of knowledge.

Making the Right Choice for Your Goal

The emphasis on certain components depends entirely on the intended application of the MPCVD system.

- If your primary focus is research and development: Prioritize a system with maximum flexibility, including precise MFCs for experimenting with gas mixtures and advanced diagnostics for analyzing the plasma in real-time.

- If your primary focus is industrial production: Emphasize system reliability, automation, and scalability, with large-area chambers and robust, repeatable process controls to ensure consistent yield.

Understanding how these core components work in concert demystifies the process of creating materials atom by atom.

Summary Table:

| Component | Primary Function | Key Feature |

|---|---|---|

| Microwave Generator | Creates plasma by ionizing gases | High-frequency energy source (e.g., 2.45 GHz) |

| Reaction Chamber | Contains the entire deposition process | Withstands high heat and low pressure |

| Gas Delivery System | Precisely mixes and injects process gases | Uses Mass Flow Controllers (MFCs) for accuracy |

| Vacuum System | Creates and maintains ultra-low pressure | Purges air and ensures plasma stability |

| Substrate Holder | Holds and heats the seed material for growth | Critical for temperature-controlled deposition |

Ready to build your advanced material synthesis capabilities?

Whether your goal is groundbreaking R&D or scalable industrial production, KINTEK's expertise in high-temperature furnace solutions translates directly to the precision engineering required for MPCVD systems. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced, customizable solutions.

Let's discuss how we can support your specific application:

- For R&D Flexibility: Tailored systems with precise controls and diagnostic capabilities.

- For Industrial Production: Robust, automated systems designed for reliability and high yield.

Contact our experts today to explore how our deep customization capabilities can meet your unique MPCVD requirements.

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems