The key features of Microwave Plasma Chemical Vapor Deposition (MPCVD) are its ability to generate a high-density, stable plasma without internal electrodes, operate over a wide pressure range, and confine the plasma away from chamber walls. This unique combination results in the growth of exceptionally high-purity, uniform thin films, most notably diamond, free from common sources of contamination.

MPCVD's primary advantage is not just using plasma, but how it creates it. By using microwaves to generate a contained, electrodeless plasma, it systematically eliminates the two main sources of contamination in deposition processes: the electrodes and the chamber walls.

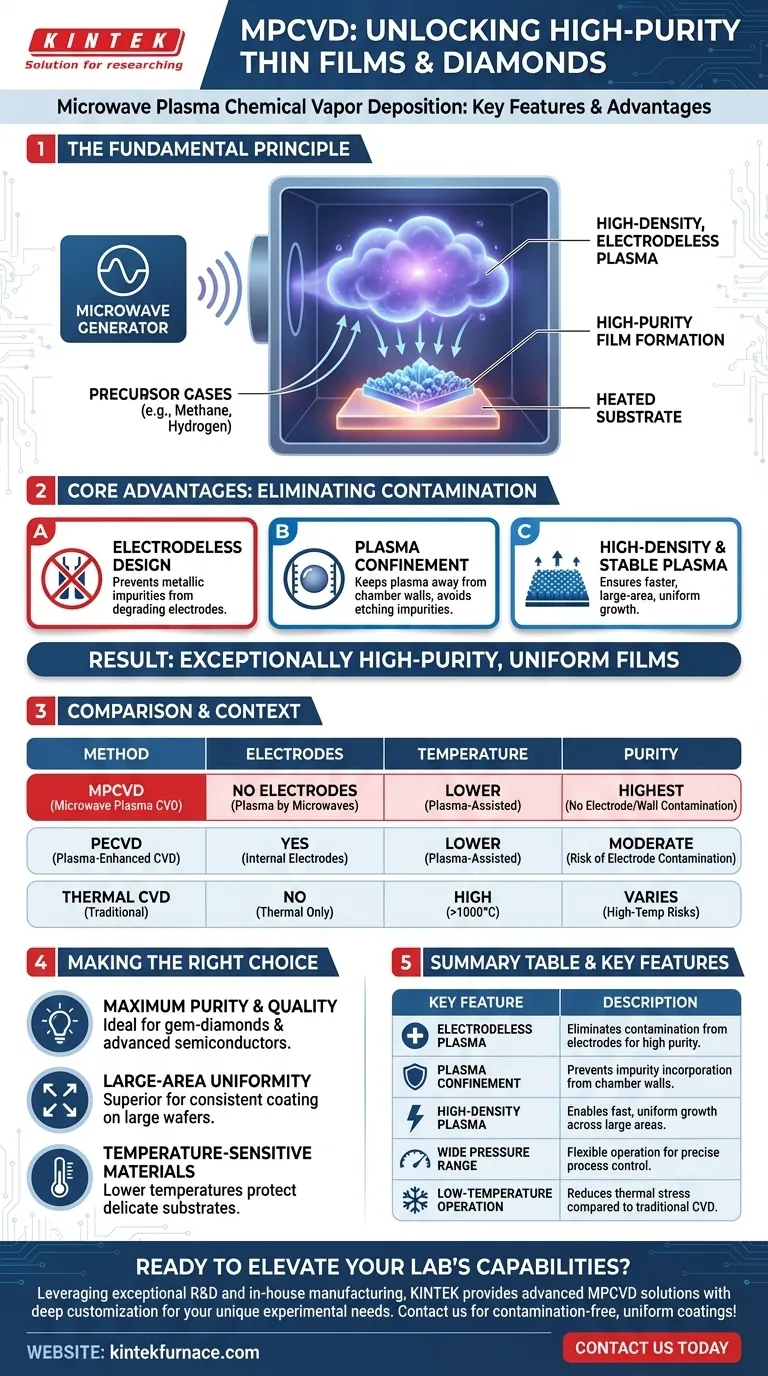

The Fundamental Principle of MPCVD

Microwave Plasma Chemical Vapor Deposition (MPCVD) is a highly refined process that uses microwave energy to facilitate the growth of thin films from a gaseous state. It represents a significant advancement over more traditional deposition techniques.

Generating Plasma with Microwaves

Instead of using direct electrical current between two electrodes, MPCVD uses a microwave generator to channel energy into a resonant cavity. This focused energy ionizes precursor gases, creating a dense and energetic plasma without any internal hardware.

Decomposing Precursor Gases

This intense plasma efficiently breaks down the precursor gases (like methane and hydrogen for diamond growth) into their highly reactive chemical components. This decomposition happens at lower overall temperatures than in purely thermal CVD processes.

Forming the High-Purity Film

These reactive species then deposit onto a heated substrate placed within the chamber. Under precisely controlled conditions of temperature, pressure, and gas flow, they arrange themselves into a crystalline structure, forming a solid, high-quality film on the substrate's surface.

Core Advantages of the MPCVD Method

The specific design of MPCVD systems gives rise to several distinct advantages, making it the preferred method for demanding applications.

Electrodeless Design Prevents Contamination

The most critical feature is the absence of internal electrodes. In other plasma systems, the electrodes can degrade and sputter, introducing metallic impurities directly into the growing film. MPCVD completely avoids this entire category of contamination.

Plasma Confinement for Ultimate Purity

The plasma is engineered to be stable and contained in the center of the chamber, away from the vacuum vessel walls. This prevents the plasma from etching the chamber material and incorporating those impurities into the film, further ensuring exceptional purity.

High-Density, Stable Plasma

Microwave energy is highly effective at creating a plasma with a high density of reactive ions and radicals. This dense, stable plasma cloud leads to faster growth rates and ensures the film is uniform across the entire substrate.

Large-Area and Uniform Deposition

Because the plasma can be generated over a large volume, MPCVD is well-suited for depositing uniform coatings on large-area substrates. This capability is crucial for industrial-scale production of electronic and optical components.

Understanding the Trade-offs and Context

No technology exists in a vacuum. Understanding where MPCVD fits in relation to other methods is key to appreciating its value.

Comparison with Traditional Thermal CVD

Traditional Chemical Vapor Deposition (CVD) relies purely on high temperatures (often >1000°C) to break down precursor gases. MPCVD uses plasma to assist this breakdown, enabling high-quality film growth at significantly lower substrate temperatures.

Comparison with PECVD

Plasma-Enhanced CVD (PECVD) also uses plasma, but it is typically generated between two electrodes. While this lowers temperature requirements, it re-introduces the risk of electrode contamination that MPCVD was specifically designed to eliminate.

The Critical Role of Process Control

The superior results of MPCVD are entirely dependent on precise process control. Factors like microwave power, gas pressure, temperature, and gas mixture ratios must be meticulously managed to achieve the desired film quality, purity, and uniformity.

Making the Right Choice for Your Application

Choosing a deposition method depends entirely on the required film properties and substrate limitations.

- If your primary focus is maximum purity and defect-free crystal quality: MPCVD is the industry benchmark, especially for materials like gem-quality diamonds and advanced semiconductors where even trace impurities are unacceptable.

- If your primary focus is coating large areas uniformly: MPCVD's ability to generate a stable, large-volume plasma makes it a superior choice for ensuring consistent film properties across large wafers or components.

- If your primary focus is depositing on temperature-sensitive materials: MPCVD offers a lower-temperature process compared to thermal CVD, protecting delicate substrates while still achieving high-quality film growth.

Ultimately, MPCVD is the definitive choice when the goal is to synthesize materials of the highest possible quality by eliminating environmental contamination.

Summary Table:

| Key Feature | Description |

|---|---|

| Electrodeless Plasma | Eliminates contamination from electrodes, ensuring high-purity film growth. |

| Plasma Confinement | Keeps plasma away from chamber walls, preventing impurity incorporation. |

| High-Density Plasma | Enables fast growth rates and uniform deposition across large areas. |

| Wide Pressure Range | Operates flexibly under various conditions for precise process control. |

| Low-Temperature Operation | Reduces thermal stress on substrates compared to traditional CVD methods. |

Ready to elevate your lab's capabilities with high-purity thin films? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced MPCVD solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to precisely meet your unique experimental needs. Contact us today to discuss how our MPCVD systems can deliver contamination-free, uniform coatings for your advanced applications!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- Why is MPCVD considered a cornerstone of modern materials science and engineering? Unlock High-Purity Materials for Innovation

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis