At its core, a high-quality porcelain furnace is defined by three critical features: exceptionally precise temperature control, uniform heat distribution throughout the chamber, and sophisticated, programmable firing cycles. These elements work in concert to transform ceramic materials into durable, esthetic restorations that precisely match the characteristics of natural teeth.

The goal is not simply to heat ceramic, but to control the entire thermal process with absolute consistency. Understanding how specific features contribute to this control is the key to predictable, high-quality results and moving beyond the manufacturer's default settings.

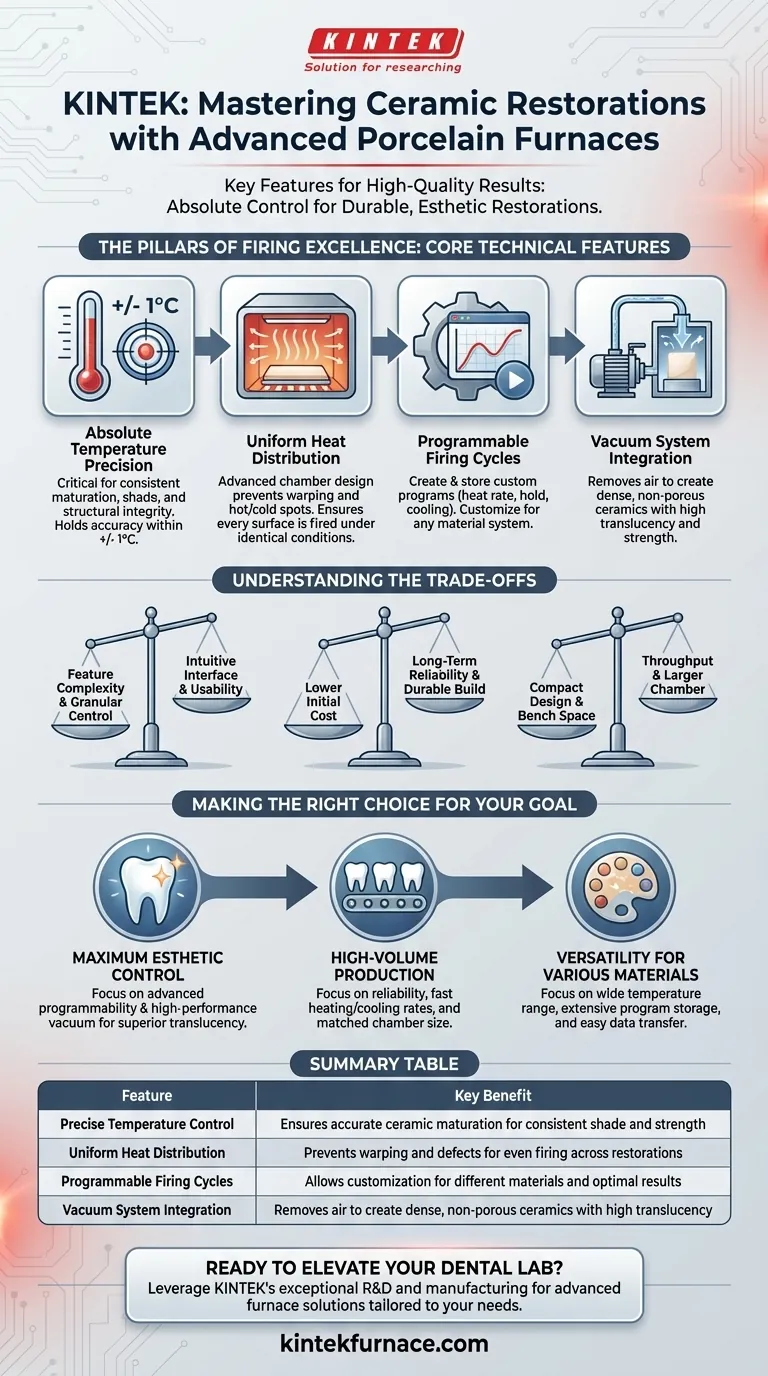

The Pillars of Firing Excellence: Core Technical Features

The final quality of any ceramic restoration is a direct result of the firing process. A superior furnace provides unwavering control over the variables that matter most.

Absolute Temperature Precision

A furnace's ability to achieve and hold a specific temperature is paramount. Modern, high-quality furnaces maintain accuracy within +/- 1° Celsius.

This level of precision is not a luxury; it is essential for the chemical and physical maturation of the ceramic. Even minor deviations can impact shade, translucency, and structural integrity.

Uniform Heat Distribution

The furnace chamber must be a zone of consistent temperature, free from hot or cold spots. This is achieved through an advanced chamber design and the strategic placement of high-quality heating elements.

Uniform heat ensures that every surface of the restoration—from a thin incisal edge to a bulky pontic—is fired under identical conditions. This prevents warping, distortion, and internal stresses that can lead to premature failure.

Programmable Firing Cycles

Different ceramic systems have unique firing requirements. The ability to create, store, and execute custom firing programs gives the technician complete control.

This includes setting the dry-out time, heating rate, target temperature, hold time, and cooling sequence. This customization is what allows a technician to master a material and produce truly bespoke restorations.

Vacuum System Integration

Firing under a vacuum is a critical step for creating dense, non-porous ceramic. A vacuum porcelain furnace removes air from the chamber before and during the heating cycle.

This process minimizes defects like bubbles and voids within the ceramic, significantly enhancing the material's strength and final esthetic result. The result is a restoration with higher translucency and a more lifelike appearance.

Understanding the Trade-offs

Choosing or operating a furnace involves balancing features against practical needs. Recognizing these trade-offs is crucial for making an informed decision.

Feature Complexity vs. Usability

An advanced furnace may offer hundreds of program slots and granular control over every parameter. While powerful, this can be overwhelming if the user interface is not intuitive.

A furnace with a clear, responsive touch-screen and logical menu structure is often more valuable than one with more features that are difficult to access and manage.

Initial Cost vs. Long-Term Reliability

The furnace must be constructed from durable, high-quality materials to withstand extreme temperatures and continuous use. Cheaper models may compromise on the quality of the heating elements, muffle, or thermocouple.

Investing in a well-built furnace from a reputable manufacturer reduces downtime, calibration frequency, and the long-term cost of ownership, ensuring consistency for years.

Compact Design vs. Throughput

Lab space is always a consideration, and many furnaces are marketed with a compact design. However, this often correlates with a smaller firing chamber.

You must weigh the benefit of saving bench space against the need to fire multiple restorations or larger bridge cases simultaneously. A furnace that is too small can quickly become a production bottleneck.

Making the Right Choice for Your Goal

The "best" furnace is the one that aligns with your lab's specific production goals and clinical philosophy. Use these points to guide your evaluation.

- If your primary focus is maximum esthetic control: Prioritize a furnace with advanced programmability for custom cycles and a high-performance vacuum system for superior translucency.

- If your primary focus is high-volume production: Look for a furnace with a reputation for reliability, fast heating/cooling rates, and a chamber size that matches your throughput needs.

- If your primary focus is versatility for various materials: Emphasize a furnace with a wide temperature range and the capacity for extensive program storage and easy data transfer (e.g., via USB).

Understanding these features empowers you to turn your furnace from a simple appliance into a precise instrument for exceptional craftsmanship.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Precise Temperature Control | Ensures accurate ceramic maturation for consistent shade and strength |

| Uniform Heat Distribution | Prevents warping and defects for even firing across restorations |

| Programmable Firing Cycles | Allows customization for different materials and optimal results |

| Vacuum System Integration | Removes air to create dense, non-porous ceramics with high translucency |

Ready to elevate your dental lab's ceramic restorations with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your workflow and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity