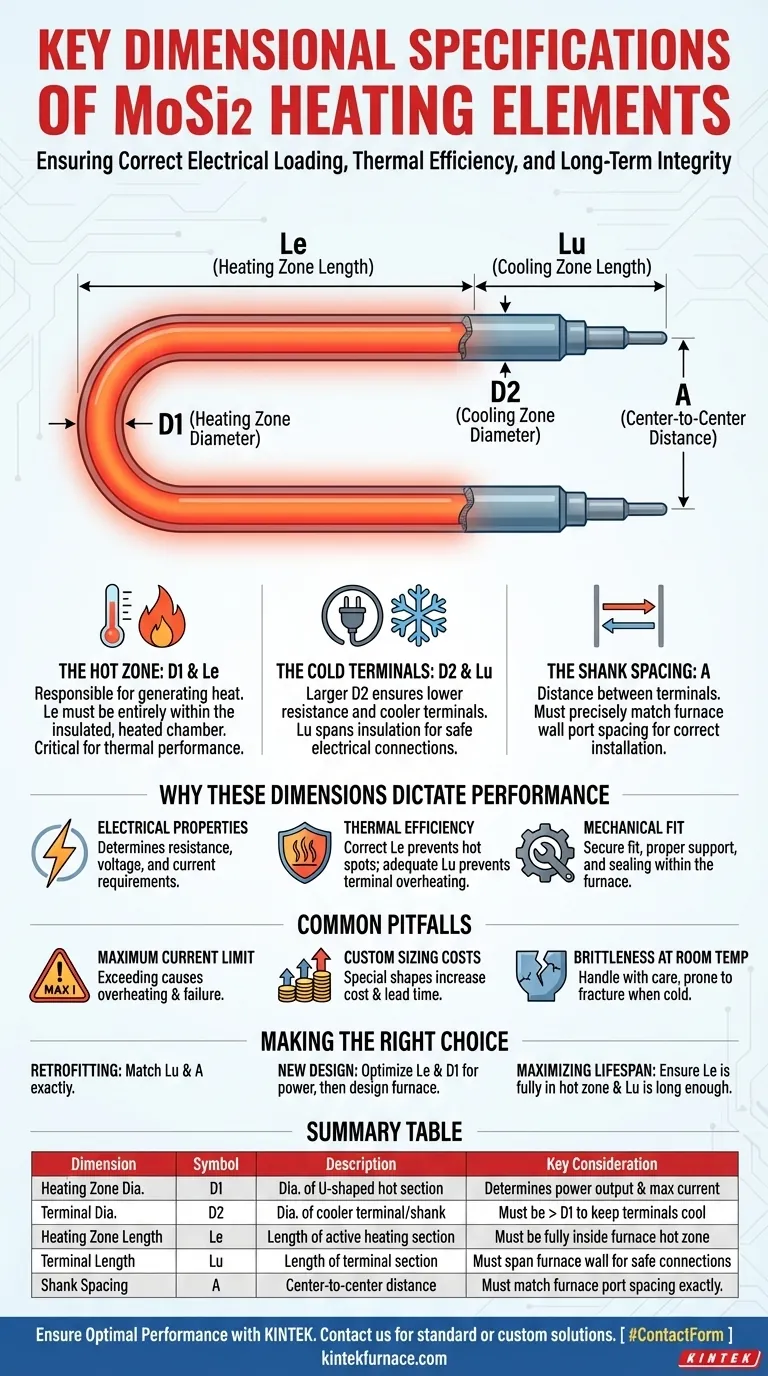

The key dimensional specifications for a Molybdenum Disilicide (MoSi2) heating element are defined by five critical measurements. These are the heating zone diameter (D1), the terminal or cooling zone diameter (D2), the heating zone length (Le), the terminal or cooling zone length (Lu), and the center-to-center spacing between the terminals (A).

Understanding these five dimensions is not just about physical fit; it's the foundation for ensuring correct electrical loading, thermal efficiency, and the long-term mechanical integrity of your high-temperature furnace.

Deconstructing the Core Dimensions

To select the correct MoSi2 element, you must understand what each dimension represents and how it interacts with your furnace geometry and heating requirements.

The Hot Zone: D1 & Le

The heating zone is the active part of the element responsible for generating heat. Its dimensions are the most critical for thermal performance.

- D1 (Heating Zone Diameter): This is the diameter of the slender, U-shaped portion of the element.

- Le (Heating Zone Length): This defines the length of that heated section. The Le must be entirely contained within the insulated, heated chamber of the furnace.

The Cold Terminals: D2 & Lu

The terminals, also called the cooling zones or shanks, are the thicker sections designed to pass through the furnace wall and connect to the power supply.

- D2 (Cooling Zone Diameter): This is the diameter of the terminals. It is always larger than D1 to ensure lower electrical resistance, which keeps the terminals cooler. Standard D1/D2 ratios include 3/6mm up to 12/24mm.

- Lu (Cooling Zone Length): This length must be sufficient to span the furnace insulation and refractory, allowing electrical connections to be made at a safe distance from the extreme heat.

The Shank Spacing: A

The shank spacing is a simple but crucial measurement for installation.

- A (Center-to-Center Distance): This is the distance between the two terminals. This dimension must precisely match the spacing of the lead-through holes in the furnace wall.

Why These Dimensions Dictate Performance

The geometry of a MoSi2 element is directly linked to its electrical and thermal behavior. Incorrectly specifying these dimensions can lead to inefficiency, premature failure, and damage to your equipment.

Impact on Electrical Properties

Each element's dimensions determine its electrical resistance. This, in turn, dictates the voltage and current required to reach a target temperature.

The diameter (D1) and length (Le) of the heating zone are the primary factors defining the element's resistance and power output.

Ensuring Thermal Efficiency

A correctly specified element concentrates heat generation entirely within the furnace chamber.

If the Le is too long and extends into the furnace insulation, it creates a hot spot that can damage the refractory. If the Lu is too short, the terminals will overheat, potentially damaging the electrical connectors.

Guaranteeing Mechanical Fit

Proper dimensions ensure the element fits securely and operates safely.

The shank spacing (A) is non-negotiable for installation in an existing furnace. The D2 and Lu dimensions must also match the furnace wall ports to provide proper support and sealing.

Common Pitfalls and Considerations

While MoSi2 elements are robust, they are not immune to issues arising from improper specification or operation.

The Maximum Current Limit

Every element, based on its specific dimensions (primarily D1), has a maximum allowable current.

Applying a current that exceeds this manufacturer-specified limit will cause the element to overheat rapidly, leading to damage and failure.

Standard vs. Custom Sizing

Standard sizes are widely available and cost-effective. However, many applications require custom dimensions.

While manufacturers can produce special shapes and sizes, this often comes with increased cost and longer lead times.

Brittleness at Room Temperature

Despite high bending and compression strength at operating temperatures, MoSi2 elements are ceramic and can be brittle when cold.

Care must be taken during installation to avoid mechanical shock or impact, as this can easily fracture the element before it is ever used.

Making the Right Choice for Your Goal

Your primary objective will determine which dimensions you need to prioritize during the specification process.

- If your primary focus is retrofitting an existing furnace: Precisely match the Lu (furnace wall thickness) and A (port spacing) of the old elements to ensure a drop-in replacement.

- If your primary focus is designing a new furnace: First, calculate the required heating power to determine the optimal Le and D1, then design the furnace wall and port geometry around those needs.

- If your primary focus is maximizing element lifespan: Ensure the Le is fully inside the hot chamber and the Lu is long enough to keep electrical connections cool, preventing thermal and electrical stress.

Correctly specifying these five core dimensions is the first and most critical step toward building a reliable, efficient, and long-lasting high-temperature heating system.

Summary Table:

| Dimension | Symbol | Description | Key Consideration |

|---|---|---|---|

| Heating Zone Diameter | D1 | Diameter of the U-shaped hot section | Determines power output and max current |

| Terminal Diameter | D2 | Diameter of the cooler terminal/shank | Must be larger than D1 to keep terminals cool |

| Heating Zone Length | Le | Length of the active heating section | Must be fully inside the furnace hot zone |

| Terminal Length | Lu | Length of the terminal section | Must span the furnace wall for safe connections |

| Shank Spacing | A | Center-to-center distance between terminals | Must match furnace wall port spacing exactly |

Ensure Optimal Performance and Longevity for Your High-Temperature Applications

Specifying the correct MoSi2 heating element dimensions is critical for your furnace's efficiency and your element's lifespan. The expert team at KINTEK is here to help you navigate these specifications, whether you need a standard replacement or a fully custom solution.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. We can provide the perfect MoSi2 elements for your specific requirements.

Contact us today to discuss your project and get a quote. Let our expertise ensure your heating system operates at its best.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency