The primary advantages of silicon carbide (SiC) heating elements are their exceptional high-temperature performance, robust durability, energy efficiency, and design versatility. These attributes make them a superior choice for demanding industrial heating processes, directly contributing to higher operational efficiency, process stability, and long-term cost savings.

Choosing silicon carbide is not just about selecting a heating component; it's a strategic decision to enhance process capability and reduce the total cost of ownership in high-temperature environments. The core benefit lies in achieving consistent, reliable heat under conditions where other materials would fail.

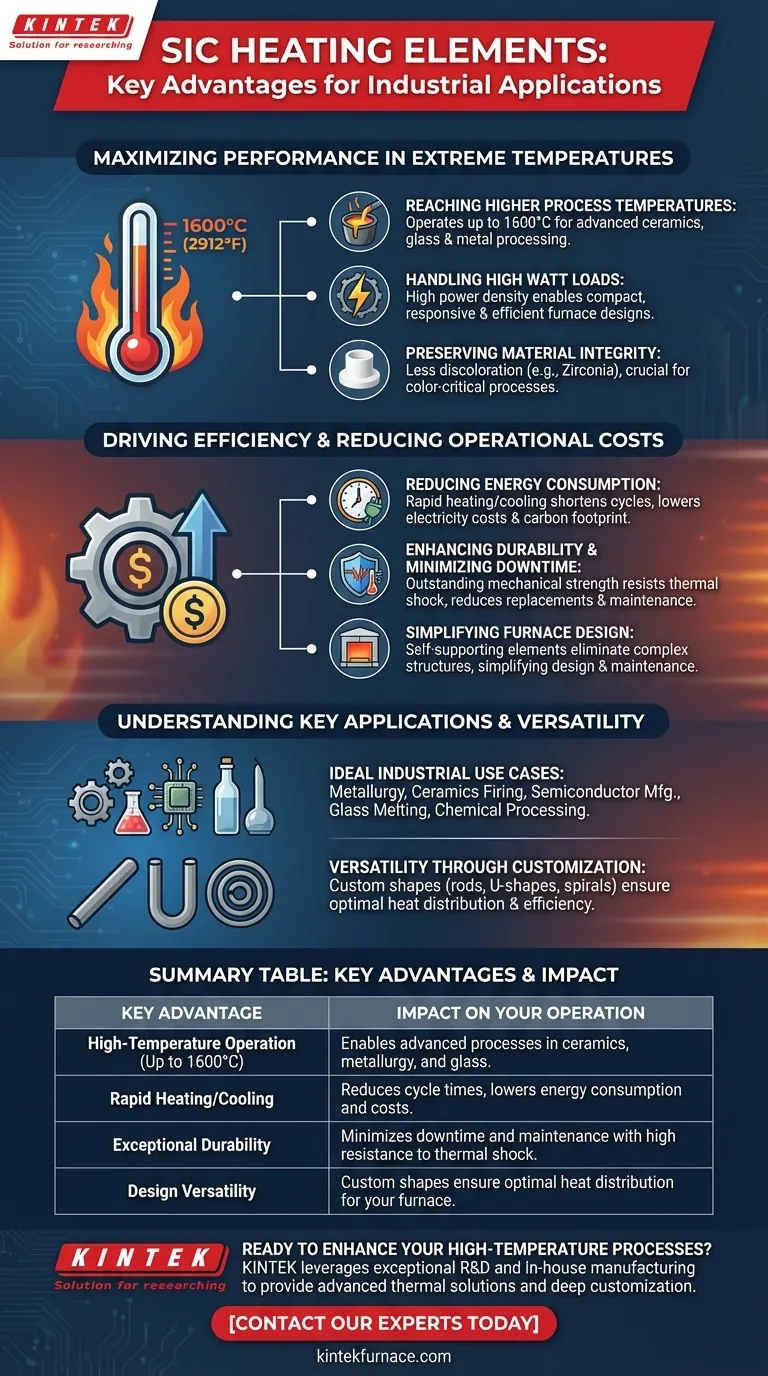

Maximizing Performance in Extreme Temperatures

The most significant advantage of SiC elements is their ability to perform reliably in extreme heat. This capability is fundamental to many modern industrial processes.

Reaching Higher Process Temperatures

SiC elements can operate at temperatures up to 1600°C (2912°F). This allows for processes that are simply not possible with many other heating materials, such as those required in advanced ceramics, glass production, and metal processing.

Handling High Watt Loads

These elements can handle high power density, or watt loading. This means you can get more heat out of a smaller element, enabling more compact, responsive, and efficient furnace and kiln designs.

Preserving Material Integrity

In certain applications, the heating element itself can affect the product. For example, SiC has a less discoloring effect on materials like zirconia compared to alternatives like Molybdenum Disilicide (MoSi2), making it essential for processes where final product color is critical.

Driving Efficiency and Reducing Operational Costs

Beyond pure temperature performance, SiC elements offer tangible benefits that lower operational expenditures and simplify maintenance.

Reducing Energy Consumption

SiC elements feature rapid heating and cooling rates. This ability to reach target temperatures quickly shortens process cycle times, minimizes wasted energy during heat-up, and ultimately lowers electricity costs and reduces an operation's carbon footprint.

Enhancing Durability and Minimizing Downtime

Engineered for outstanding mechanical strength, SiC elements are highly resistant to breakage from thermal shock and physical stress. This durability reduces the frequency of replacements, lowers maintenance labor costs, and, most importantly, minimizes costly unplanned production downtime.

Simplifying Furnace Design

Many SiC elements are self-supporting, meaning they do not require complex and costly support structures inside the furnace. This simplifies the initial design and construction of the heating equipment and makes element replacement far easier.

Understanding the Key Applications

The unique combination of properties makes SiC the ideal choice for a range of specific, high-value industrial sectors where performance and reliability are non-negotiable.

Ideal Industrial Use Cases

SiC is the preferred element in industries such as metallurgy, ceramics firing, semiconductor manufacturing, and glass melting. Its resistance to corrosion and oxidation also makes it valuable for chemical processing applications.

Versatility Through Customization

SiC elements can be manufactured in a wide variety of shapes and sizes, including rods, U-shapes, and spirals. This allows heating systems to be precisely tailored to the unique requirements of a specific furnace, ensuring optimal heat distribution and efficiency.

Making the Right Choice for Your Goal

When evaluating SiC, consider how its advantages align with your primary operational objective.

- If your primary focus is process speed and throughput: The rapid heating capability of SiC directly minimizes cycle times and boosts productivity.

- If your primary focus is operating in extreme heat (above 1400°C): SiC's reliable performance up to 1600°C makes it a clear choice for demanding applications in glass, ceramics, and metallurgy.

- If your primary focus is minimizing total cost of ownership: The combination of energy efficiency, long service life, and low maintenance makes SiC a highly cost-effective solution over its entire lifecycle.

Ultimately, integrating SiC heating elements allows you to build more capable, efficient, and reliable high-temperature industrial processes.

Summary Table:

| Key Advantage | Impact on Your Operation |

|---|---|

| High-Temperature Operation (Up to 1600°C / 2912°F) | Enables advanced processes in ceramics, metallurgy, and glass. |

| Rapid Heating/Cooling | Reduces cycle times, lowers energy consumption and costs. |

| Exceptional Durability | Minimizes downtime and maintenance with high resistance to thermal shock. |

| Design Versatility | Custom shapes (rods, U-shapes) ensure optimal heat distribution for your furnace. |

Ready to enhance your high-temperature processes with reliable SiC heating elements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions for diverse laboratories and industries. Our product line, including high-performance Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Let us help you achieve superior process stability, efficiency, and long-term cost savings. Contact our experts today to discuss your specific application needs!

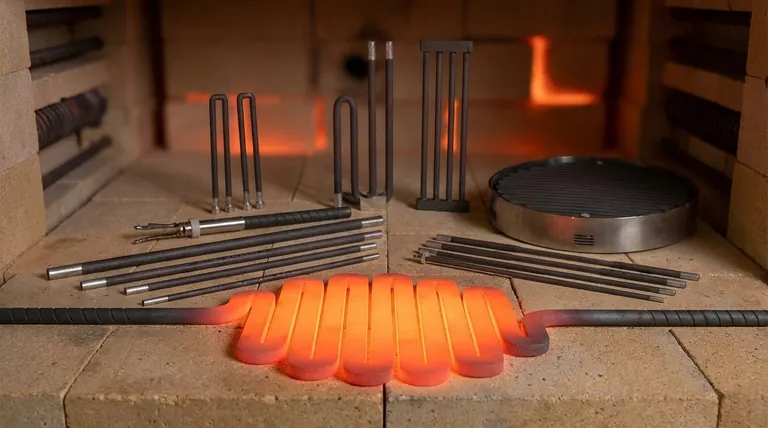

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance