At its core, the Microwave Plasma Chemical Vapor Deposition (MPCVD) method stands apart for its unique ability to deliver exceptional material purity, process stability, and industrial scalability. Unlike competing techniques, MPCVD uses microwaves to generate a plasma, which eliminates a primary source of contamination. This clean, controllable environment allows for the consistent and reproducible growth of high-quality materials, such as diamond films and crystals, over long periods and large areas.

While other deposition methods exist, MPCVD's electrode-less design is its defining feature. This fundamentally removes a key source of contamination, enabling a level of process control and reproducibility that is essential for scaling up to the industrial production of advanced materials for electronics, optics, and beyond.

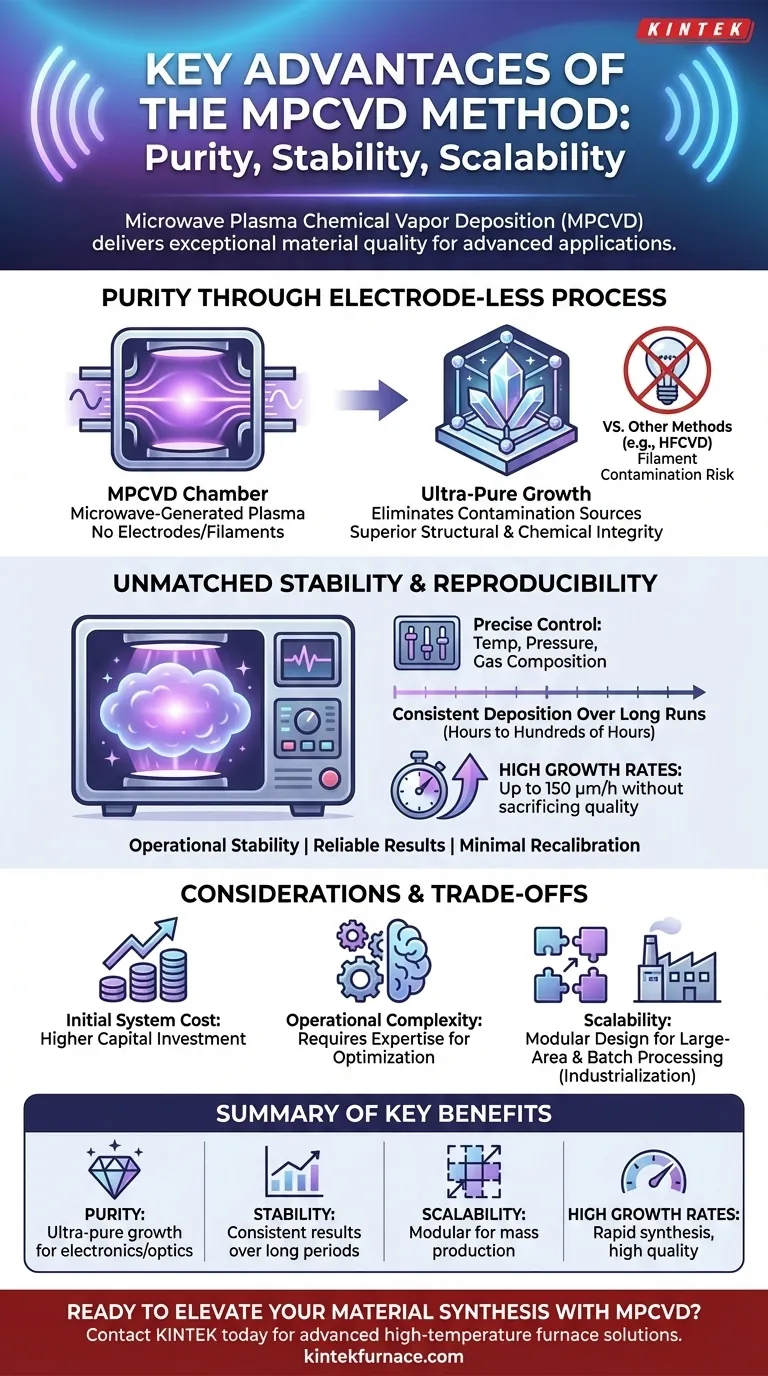

The Core Advantage: Purity Through an Electrode-less Process

The most significant advantage of MPCVD stems from how it generates the energy needed for deposition. It is an inherently clean process.

How It Works: Plasma Without Contamination

An MPCVD system uses a microwave generator to ionize a gas mixture inside a reaction chamber, creating a stable plasma. This process is "electrode-less," meaning there are no hot metal filaments or electrodes inside the chamber that can degrade and introduce impurities into the material being grown.

This directly contrasts with other methods, such as Hot Filament CVD (HFCVD), where contamination from the filament is a persistent challenge.

The Impact on Material Quality

The absence of internal electrodes ensures an ultra-pure growth environment. This is critical for applications where even trace amounts of contaminants can compromise performance, such as in electronic devices or high-power optics.

The result is a final product with superior structural and chemical integrity, directly attributable to the purity of the deposition process itself.

Achieving Unmatched Stability and Reproducibility

For any industrial or scientific process, getting the same high-quality result every time is paramount. MPCVD is engineered for this level of reliability.

Precise Control Over Growth Conditions

The microwave-generated plasma is remarkably stable, allowing for precise and independent control over critical parameters like temperature, pressure, and gas composition. This creates a large, uniform plasma area ideal for consistent deposition.

This level of control ensures that the growth conditions remain constant, whether the process runs for an hour or for hundreds of hours.

Consistency Over Long Production Runs

MPCVD systems are known for their operational stability and reproducibility. This allows for continuous deposition over extended periods without a decline in the quality of the resulting film or crystal.

Furthermore, modern systems using solid-state power generators maintain their working parameters even if a component is replaced, eliminating the need for extensive recalibration and minimizing downtime.

High Growth Rates with Quality

MPCVD is capable of achieving high growth rates, with some systems reaching up to 150 µm/h. This allows for the rapid synthesis of thick films or large crystals without sacrificing the purity and quality the method is known for, making it economically viable for mass production.

Understanding the Trade-offs and Considerations

No technology is without its complexities. While powerful, MPCVD requires a clear understanding of its operational demands to be leveraged effectively.

Initial System Cost

MPCVD reactors are sophisticated pieces of equipment. The initial capital investment for a system—including the microwave generator, vacuum chamber, and control systems—is typically higher than for simpler methods like HFCVD.

Operational Complexity

Achieving optimal results requires significant expertise. While the process is stable once dialed in, the initial optimization of parameters like gas mixture, power, and pressure can be complex and time-consuming.

Scalability and Design

The modular and scalable architecture of MPCVD is a key advantage for industrialization. It allows the technology to be adapted for coating very large substrates or for batch processing, which is essential for moving from laboratory research to factory production.

Making the Right Choice for Your Goal

Selecting MPCVD depends entirely on your project's primary objective, as its strengths are most apparent in demanding applications.

- If your primary focus is foundational research or prototyping: MPCVD provides the highest purity and reproducibility, ensuring your experimental results are reliable and free from process-induced variables.

- If your primary focus is industrial coating applications: The method's scalability and stability over large areas make it ideal for producing uniform, durable coatings for tools, optics, or thermal management on an industrial scale.

- If your primary focus is creating large, high-quality single crystals: MPCVD is the leading technology, offering the best path toward the cost-effective mass production of gem-quality diamonds and materials for next-generation electronics.

Ultimately, MPCVD's advantages position it as the premier technology for any application where material purity and process scalability are non-negotiable.

Summary Table:

| Advantage | Key Details |

|---|---|

| Purity | Electrode-less process eliminates contamination, ensuring ultra-pure growth for electronics and optics. |

| Stability & Reproducibility | Precise control over temperature, pressure, and gas composition for consistent results over long runs. |

| Scalability | Modular design supports large-area coatings and batch processing for industrial mass production. |

| High Growth Rates | Capable of up to 150 µm/h, enabling rapid synthesis without quality loss. |

Ready to elevate your material synthesis with MPCVD technology? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your lab. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our MPCVD systems can deliver superior purity, stability, and scalability for your projects in electronics, optics, and beyond!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is Microwave Plasma Chemical Vapor Deposition (MPCVD)? Unlock Ultra-Pure Diamond Synthesis

- What advantages do MPCVD diamond tools offer in industrial applications? Maximize Lifespan & Efficiency

- What are the differences in film quality between PVD and CVD? Discover the Best Method for Your Application

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- What are the key features of MPCVD single crystal diamond deposition equipment? Precision Control for High-Quality Growth