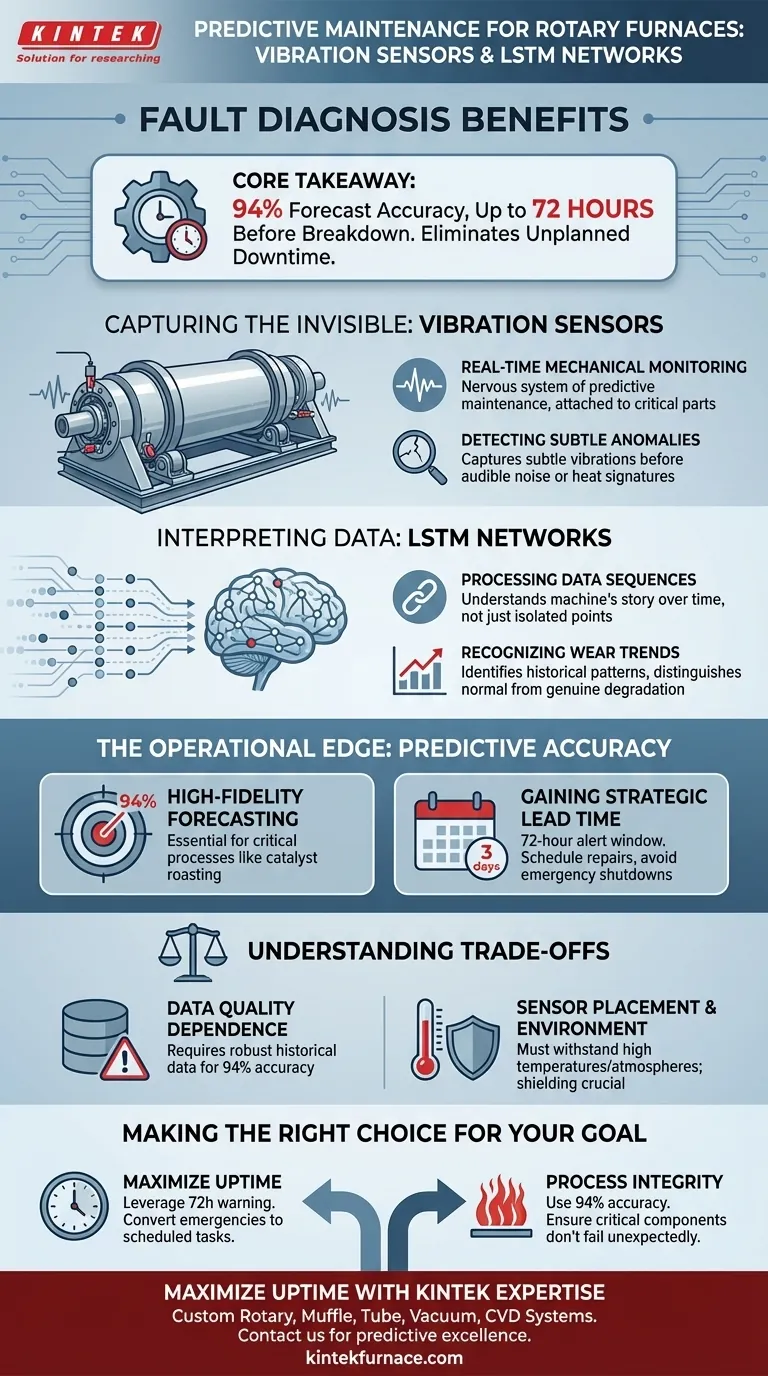

The integration of vibration sensors with Long Short-Term Memory (LSTM) networks transforms maintenance from a reactive necessity into a precise, predictive strategy. By capturing real-time mechanical subtleties and analyzing them against historical wear trends, this system provides high-accuracy failure forecasts that protect critical high-temperature assets.

Core Takeaway: This technical combination enables a shift from reactive repairs to predictive maintenance, offering 94% forecast accuracy up to 72 hours before a breakdown occurs. This advanced warning is critical for eliminating unplanned downtime in complex rotary furnace operations.

Capturing the Invisible: The Role of Vibration Sensors

Real-Time Mechanical Monitoring

Vibration sensors serve as the nervous system of the predictive maintenance architecture. They are attached directly to critical rotating parts, such as the bearings of the rotary furnace system.

Detecting Subtle Anomalies

These sensors capture subtle mechanical vibrations in real-time that human operators often miss. They detect early signs of distress long before they manifest as audible noise or catastrophic heat signatures.

Interpreting the Data: How LSTM Networks Function

Processing Data Sequences

Unlike standard algorithms that analyze isolated data points, Long Short-Term Memory (LSTM) networks are designed to process sequences of data. They understand the "story" of the machine over time.

Recognizing Wear Trends

LSTM networks analyze the stream of vibration data to identify specific historical wear patterns. They compare current sensor inputs against learned behaviors to distinguish between normal operational variance and genuine degradation.

The Operational Edge: Predictive Accuracy

High-Fidelity Forecasting

The primary benefit of this synergy is precision. The system allows operators to forecast failures with 94% accuracy. This level of reliability is essential for furnaces that manage critical processes like catalyst roasting or atmosphere control.

Gaining Strategic Lead Time

The system provides alerts up to 72 hours before a breakdown actually occurs. This three-day window allows maintenance teams to schedule repairs during planned shifts rather than suffering the costs of emergency shutdowns.

Understanding the Trade-offs

Data Quality Dependence

The accuracy of an LSTM network is directly tied to the quality of the data it is trained on. To achieve 94% accuracy, the system requires a robust set of historical data representing both healthy operations and past failure modes.

Sensor Placement and Environment

Rotary furnaces operate in high-temperature environments often involving inert or oxidizing atmospheres. Sensors must be carefully shielded and precisely calibrated to withstand these conditions without producing noisy, unreliable data.

Making the Right Choice for Your Goal

To determine if this predictive maintenance solution fits your operational strategy, consider your primary objectives:

- If your primary focus is Maximizing Uptime: Leverage the 72-hour warning window to convert emergency repairs into scheduled maintenance tasks, ensuring continuous production.

- If your primary focus is Process Integrity: Use the 94% accuracy rate to ensure that critical rotating components—essential for uniform heating and eliminating cold spots—never fail unexpectedly during sensitive processing.

Ultimately, adopting this technology allows you to move from repairing broken equipment to managing the health of active assets.

Summary Table:

| Feature | Vibration Sensors | LSTM Networks |

|---|---|---|

| Function | Real-time mechanical monitoring | Sequential data analysis & trend recognition |

| Capability | Detects subtle, invisible anomalies | Distinguishes normal variance from degradation |

| Key Outcome | Captures raw mechanical distress | Provides 94% forecast accuracy |

| Strategic Gain | Prevents catastrophic failure | Offers 72-hour maintenance lead time |

Maximize Uptime with KINTEK Expertise

Don't let unplanned downtime disrupt your critical high-temperature processes. Backed by expert R&D and manufacturing, KINTEK offers high-performance Rotary, Muffle, Tube, Vacuum, and CVD systems—all fully customizable to integrate advanced monitoring for your unique needs.

Ready to shift from reactive repairs to predictive excellence? Contact our specialists today to discover how our lab-grade furnace solutions and technical expertise can safeguard your production and enhance process integrity.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the differences between batch-type and continuous-type rotary kilns? Choose the Right Kiln for Your Production Needs

- What role do rotary furnaces play in aluminum processing? Efficient Melting and Versatile Thermal Solutions

- How does a rotary tube furnace operate in terms of fuel and heating? Discover Dynamic Heating for Uniform Results

- What makes rotary tube furnaces user-friendly? Achieve Superior Process Uniformity and Efficiency

- How does the rotation mechanism in a rotary tube furnace benefit CVD processes? Achieve Uniform Coatings and Boost Efficiency

- What is a rotary tube furnace and its primary function in Chemical Vapor Deposition (CVD)? Achieve Uniform Powder Coating

- In what ways are rotary furnaces environmentally friendly? Boost Energy Efficiency & Waste Recycling

- What are the characteristics of the refractory materials used in rotary kilns? Essential for Durability & Efficiency