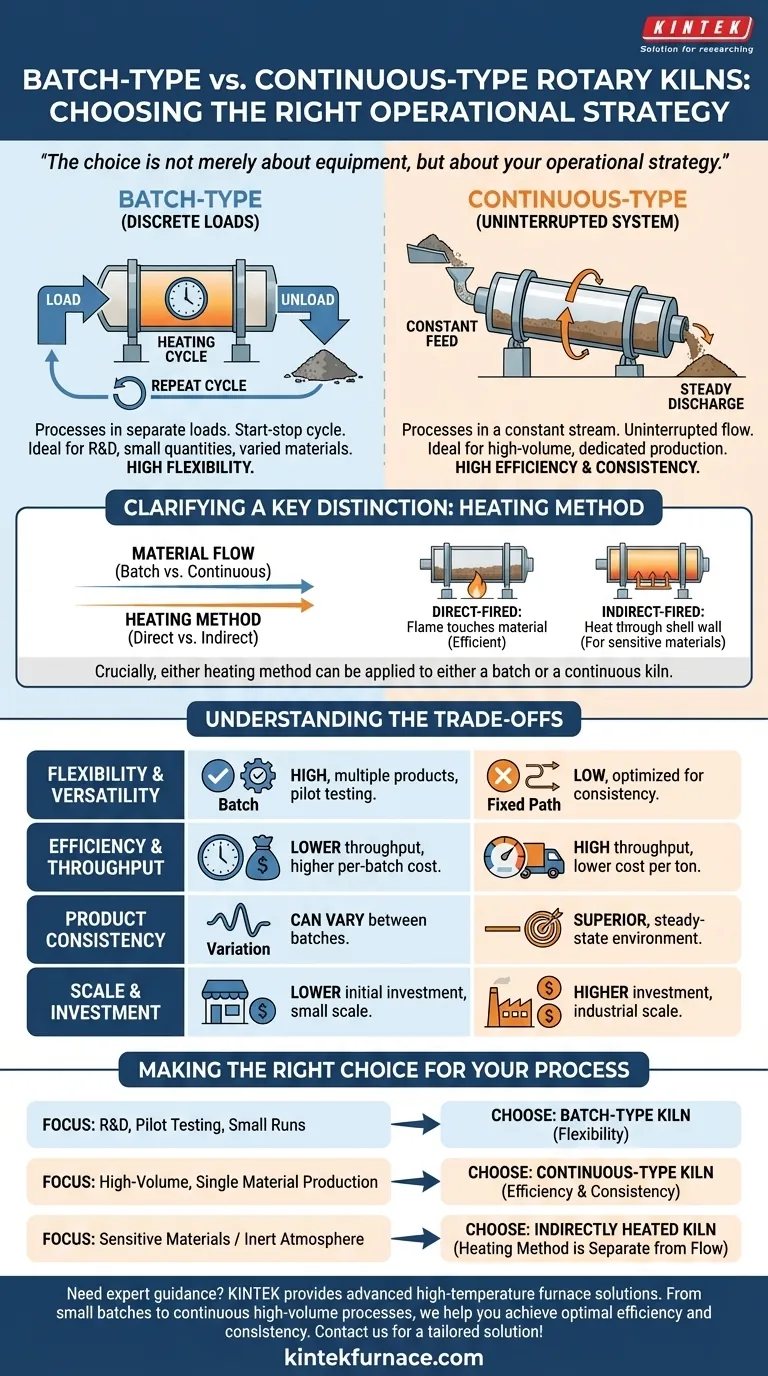

At its core, the difference between batch and continuous rotary kilns lies in their material handling philosophy. A batch-type kiln processes material in distinct, separate loads, following a complete cycle of loading, heating, and unloading for each one. In contrast, a continuous-type kiln operates as an uninterrupted system, with raw material constantly fed into one end and finished product steadily discharged from the other.

The choice is not merely about equipment, but about your operational strategy. Batch kilns offer flexibility for varied, smaller-scale tasks, while continuous kilns deliver efficiency and consistency for high-volume, dedicated production lines.

The Fundamental Operational Difference

To select the right kiln, you must first understand how each type fundamentally operates and how that impacts your production flow.

How Batch-Type Kilns Work

A batch kiln functions like a large, industrial oven. An entire "batch" of material is loaded into the kiln at once.

The kiln then runs through a pre-set heating profile to process the material. Once the thermal treatment is complete, the entire batch is discharged. This cycle repeats for each new load.

This discrete, start-and-stop process makes it ideal for research and development, processing small quantities, or handling a wide variety of different materials that require unique processing parameters.

How Continuous-Type Kilns Work

A continuous kiln operates more like an assembly line. Material is fed into the elevated end of the rotating drum at a controlled, constant rate.

As the kiln rotates, the material tumbles and flows steadily down the length of the drum, undergoing the thermal reaction as it travels. By the time it reaches the discharge end, the process is complete.

This method is built for efficiency at scale. It maintains a stable thermal environment, ensuring high product consistency for large volumes of the same material.

Clarifying a Key Distinction: Heating Method

A common point of confusion is mixing up the material flow (batch vs. continuous) with the heating method. These are two separate design choices.

The Batch vs. Continuous Axis: How Material Moves

As we've established, this choice is about whether your material is processed in discrete loads or in a constant stream. It dictates the operational logistics of your facility.

The Direct vs. Indirect Axis: How Material is Heated

This is a separate, equally important decision.

- Direct-fired kilns allow the process gas and flame to come into direct contact with the material. This is efficient but can only be used if the material will not be negatively affected by the combustion byproducts.

- Indirect-fired kilns heat the material by warming the outside of the rotating shell. The heat transfers through the shell wall to the material inside, which never touches the flame. This is essential for sensitive materials or when an inert atmosphere is required.

Crucially, either heating method can be applied to either a batch or a continuous kiln. You can have a direct-fired continuous kiln, an indirect-fired batch kiln, and so on.

Understanding the Trade-offs

Your decision will be guided by balancing the inherent advantages and disadvantages of each operational style.

Flexibility and Versatility

Batch kilns are the clear winner here. Their ability to stop, clean, and start a new cycle with different parameters makes them perfect for facilities that produce multiple products or conduct pilot-scale testing.

Efficiency and Throughput

Continuous kilns are built for high throughput. By eliminating the downtime between cycles, they can process enormous volumes of material. This results in a lower operational cost per ton of product in large-scale applications.

Product Consistency

Because they maintain a steady-state thermal environment, continuous kilns generally offer superior product consistency. Each particle experiences a nearly identical journey. Batch kilns can have slight variations between batches if conditions are not perfectly replicated.

Scale and Investment

Batch systems are typically suited for smaller-scale needs and often represent a lower initial capital investment. Continuous systems are a significant investment intended for dedicated, industrial-scale production.

Making the Right Choice for Your Process

Evaluate your primary goal to determine the best path forward for your specific application.

- If your primary focus is R&D, pilot testing, or producing small runs of diverse materials: A batch-type kiln provides the necessary operational flexibility.

- If your primary focus is high-volume, cost-effective production of a single material: A continuous-type kiln will deliver the efficiency and consistency you require.

- If your primary focus is processing materials sensitive to contamination or requiring an inert atmosphere: Your priority is choosing an indirectly heated kiln, a decision that is independent of whether your process is batch or continuous.

Understanding the distinct axes of material flow and heating method is the key to designing the optimal thermal processing system for your goal.

Summary Table:

| Feature | Batch-Type Kiln | Continuous-Type Kiln |

|---|---|---|

| Material Handling | Processes in discrete loads | Processes in a constant stream |

| Ideal For | R&D, small-scale, varied materials | High-volume, dedicated production |

| Flexibility | High, allows parameter changes | Low, optimized for consistency |

| Efficiency | Lower throughput, higher per-batch cost | High throughput, lower cost per ton |

| Product Consistency | Can vary between batches | Superior, steady-state environment |

| Initial Investment | Typically lower | Higher, for industrial scale |

Need expert guidance to select the perfect kiln for your laboratory or production line? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're handling small batches or continuous high-volume processes, we'll help you achieve optimal efficiency and consistency. Contact us today to discuss your specific needs and get a tailored solution!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained