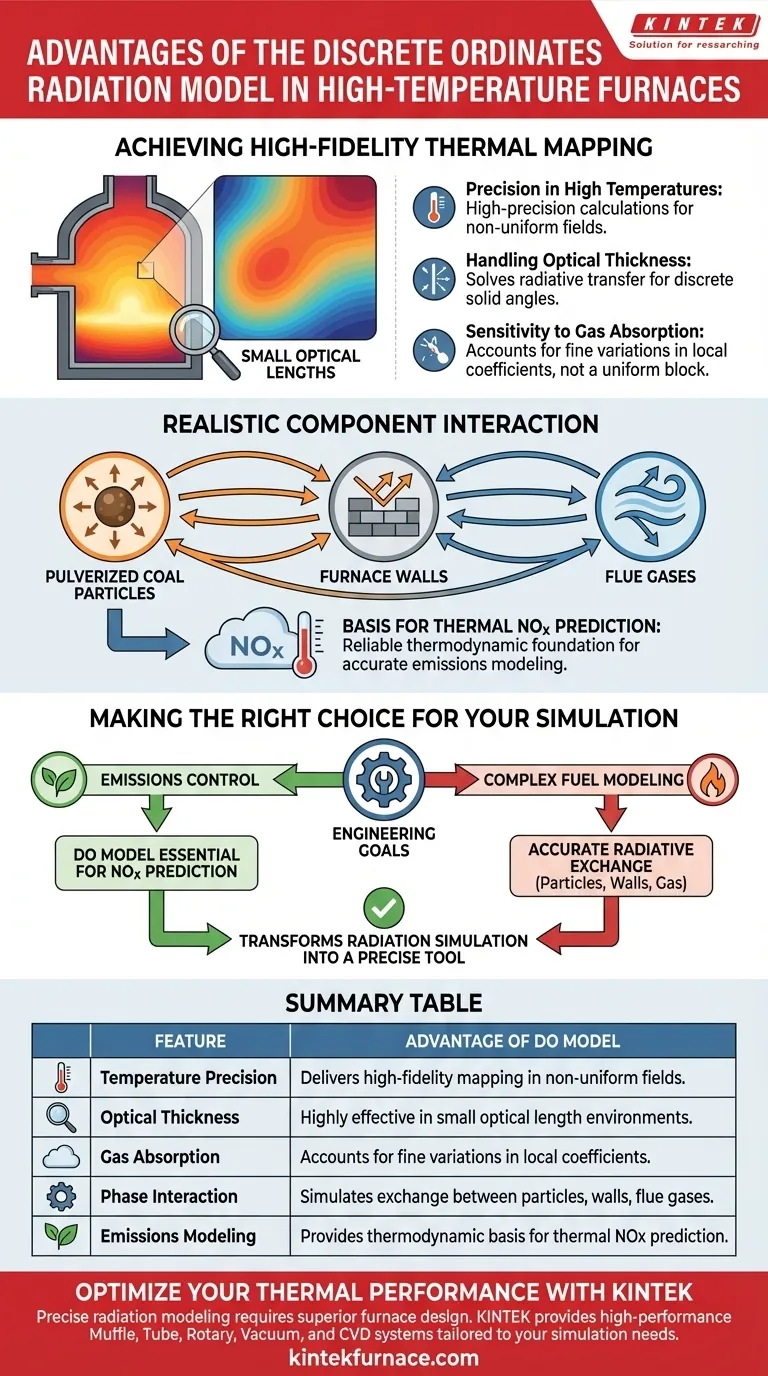

The Discrete Ordinates (DO) radiation model is the preferred choice for achieving high-precision temperature distribution calculations in high-temperature furnace environments. It is specifically advantageous in scenarios with small optical lengths, where it accounts for fine variations in gas absorption coefficients to deliver a realistic simulation of energy exchange.

By accurately modeling the complex interactions between pulverized particles, furnace walls, and flue gases, the DO model provides the rigorous thermodynamic foundation required to predict sensitive outcomes like thermal NOx formation.

Achieving High-Fidelity Thermal Mapping

Precision in High Temperatures

In high-temperature furnace environments, standard radiation models often struggle with accuracy. The DO model excels here by delivering high-precision calculations regarding temperature distribution.

This level of accuracy is critical when the thermal field is non-uniform or when exact temperature peaks must be identified to ensure equipment safety and process efficiency.

Handling Optical Thickness

The DO model is particularly effective in environments characterized by small optical lengths.

While some models simplify radiation transport in optically thin media, the DO model solves the radiative transfer equation for specific discrete solid angles, ensuring validity even when optical thickness is low.

Sensitivity to Gas Absorption

A distinct advantage of this model is its ability to account for fine variations in gas absorption coefficients.

Rather than treating the gas medium as a uniform block, the DO model recognizes local differences in how gases absorb and emit radiation, leading to a much more granular and accurate thermal profile.

Realistic Component Interaction

Simulating Multi-Phase Exchange

Furnaces often contain a mix of distinct elements. The DO model realistically simulates the energy exchange between three critical components:

- Pulverized coal particles

- Furnace walls

- Flue gases

This capability ensures that the simulation captures the radiative feedback loops between the fuel source, the containment boundaries, and the combustion byproducts.

The Basis for NOx Prediction

One of the most valuable downstream benefits of using the DO model is its impact on emissions modeling.

Because it provides a reliable thermodynamic basis, it enables the accurate prediction of thermal NOx formation. Since thermal NOx is highly dependent on peak flame temperatures, the precision of the DO model is essential for environmental compliance studies.

Understanding the Trade-offs

Specificity of Application

While the DO model is highly precise, the reference highlights its specific utility in high-temperature environments with small optical lengths.

Users should be aware that this precision regarding "fine variations" and particle-gas interactions implies a level of complexity that is necessary for detailed phenomena like NOx formation. Using this model implies a commitment to capturing these minute details, which may be unnecessary for simpler simulations where coarse temperature averages suffice or where optical thickness is large and uniform.

Making the Right Choice for Your Simulation

To determine if the Discrete Ordinates model is the correct tool for your project, consider your specific engineering goals:

- If your primary focus is emissions control: The DO model is essential because it provides the precise thermodynamic basis required to predict thermal NOx formation.

- If your primary focus is complex fuel modeling: Use this model to accurately capture the radiative energy exchange between pulverized coal particles and the surrounding gas and walls.

The DO model transforms radiation simulation from a general approximation into a precise tool capable of capturing the subtle physics of high-temperature combustion.

Summary Table:

| Feature | Advantage of DO Radiation Model |

|---|---|

| Temperature Precision | Delivers high-fidelity thermal mapping in non-uniform fields. |

| Optical Thickness | Highly effective in environments with small optical lengths. |

| Gas Absorption | Accounts for fine variations in local gas absorption coefficients. |

| Phase Interaction | Simulates energy exchange between particles, walls, and flue gases. |

| Emissions Modeling | Provides the thermodynamic basis for accurate thermal NOx prediction. |

Optimize Your Thermal Performance with KINTEK

Precise radiation modeling is the first step toward superior furnace design. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your exact simulation requirements. Whether you are focusing on emissions control or complex material processing, our customizable high-temperature lab furnaces ensure your real-world results match your high-fidelity models.

Ready to elevate your research and production efficiency? Contact our engineering team today to find the perfect furnace solution for your unique needs.

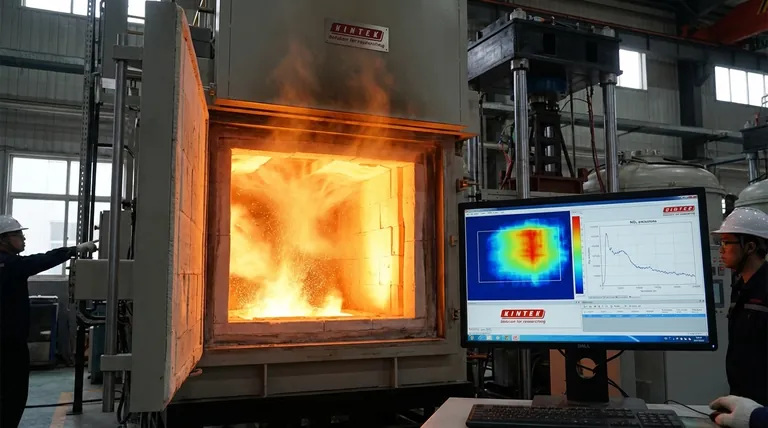

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a dual-stage salt bath design address steel wire sorbitization? Master Precision Gradient Cooling

- How do digital technical summaries assist the scientific community? Unlocking Lab High-Temp Furnace Insights

- Why Use a Laboratory Drying Oven for Re2O7/Al2O3 Catalysts? Ensure High Dispersion & Performance

- Why is annealing in a heat treatment furnace performed on graphite flake/copper composite samples before performance testing? Ensure Data Integrity for Precision Thermal Expansion Measurements

- What are the advantages of using magnetron sputtering equipment compared to MBE? Scalable 2D Transistor Solutions

- Why is a nitrogen protection system necessary for LPF resin synthesis? Ensure Purity in Lab Polymerization

- Why is a high-precision blast drying oven used for Ni-Co/Ca catalyst preparation? Ensure Structural Integrity

- What chemical processes utilize electric furnaces? Achieve Unmatched Precision and Purity