Digital technical summaries act as a critical translator for the scientific community. They convert the dense, complex engineering specifications of high-temperature furnaces—such as Muffle, Tube, and CVD systems—into accessible, practical insights. This allows researchers to rapidly assess equipment capabilities without getting bogged down in impenetrable technical jargon.

Digital summaries serve as an essential bridge between advanced thermal engineering and scientific application. By simplifying complex specifications into readable highlights, they enable researchers to identify the right tools quickly and accelerate the adoption of new processing techniques.

Bridging the Gap Between Engineering and Application

Deciphering Complex Specifications

High-temperature laboratory furnaces are engineered with intricate mechanical and electrical specifications. Whether dealing with Muffle, Tube, or Chemical Vapor Deposition (CVD) systems, the raw data can be overwhelming.

Digital technical summaries strip away the density of this engineering data. They distill complex parameters into a format that is immediately digestible for a broader scientific audience.

Contextualizing Equipment Capabilities

Researchers need to understand what a furnace can do for their specific experiment, not just how it is constructed. These summaries shift the focus from abstract mechanical design to practical application.

By presenting data in a readable format, the summaries clarify the specific capabilities of the hardware. This ensures the user understands exactly how the equipment can be applied to their unique thermal processing requirements.

The Operational Impact on Research

Accelerating Decision Making

In a laboratory environment, efficiency is paramount. Scientists often do not have the time to decipher comprehensive engineering manuals during the initial search phase.

Digital highlights allow for rapid evaluation. Researchers can quickly determine if a specific furnace model aligns with their experimental parameters, saving significant time during the equipment selection process.

Driving Technology Adoption

Advanced thermal processing techniques are only useful if they are understood and utilized. Complex specs can create a barrier to entry for new technology.

By making advanced furnace technology accessible, these summaries accelerate adoption. They help the scientific community feel comfortable integrating new, high-performance tools into their workflows faster than they would otherwise.

Understanding the Limitations

The Risk of Oversimplification

While clarity is valuable, a summary inherently condenses information. There is a trade-off between readability and granularity.

A digital summary may omit minute technical details regarding tolerances or safety margins. Relying exclusively on a high-level highlight for critical engineering constraints can lead to oversight.

The Distinction Between Screening and Specification

These summaries should be viewed as an introduction, not a manual. They are excellent for identifying potential candidates but cannot replace the full technical documentation required for final safety and operational planning.

Maximizing the Value of Technical Highlights

Use digital technical summaries as a strategic filter to streamline your laboratory equipment selection.

- If your primary focus is Rapid Screening: Use the summaries to quickly shortlist Muffle, Tube, or CVD systems that match your general temperature and processing criteria.

- If your primary focus is Technical Implementation: Use the summary to understand the general capabilities, but verify exact engineering tolerances against the full manufacturer specifications.

Ultimately, these digital tools empower you to focus less on deciphering specifications and more on the success of your research.

Summary Table:

| Feature | Engineering Specifications | Digital Technical Summaries |

|---|---|---|

| Focus | Raw mechanical/electrical data | Practical application & insights |

| Complexity | High (Dense jargon) | Low (Immediately digestible) |

| Primary Goal | Detailed construction/safety | Rapid evaluation & screening |

| Decision Speed | Slow (Manual interpretation) | Fast (Condensed highlights) |

| Ideal Use Case | Operational planning | Equipment selection & adoption |

Elevate Your Research with Precision Thermal Solutions

Navigating the complexities of high-temperature processing shouldn't slow down your scientific breakthroughs. KINTEK empowers the scientific community with advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, all backed by expert R&D and precision manufacturing.

Whether you need a standard setup or a customizable solution tailored to your unique experimental needs, our technical expertise ensures you get the right tool for the job.

Ready to accelerate your laboratory workflows? Contact us today to consult with our specialists and find the perfect high-temperature furnace for your next project.

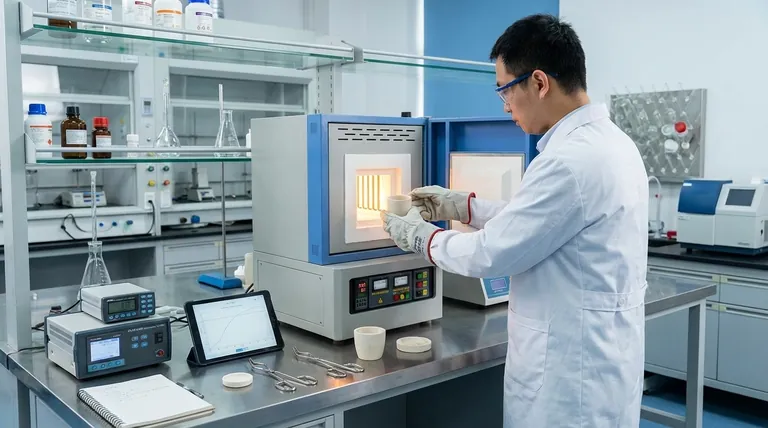

Visual Guide

References

- Cu‐Content Engineering in FeCoNiCuAl High‐Entropy Alloy Precursors: A Pathway to Advanced HEA‐Derived Sulfide Electrocatalysts for Efficient Oxygen Evolution Reaction. DOI: 10.1002/cctc.202500147

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of an ultra-high vacuum sputtering system with multi-target for CuGaO2? Precision Synthesis Guide

- What is the role of a sealed heating reactor in MSNs synthesis? Master Precision Pore Uniformity

- What role do high-temperature sintering furnaces play in ceramic SLA? Unlock 99% Density in 3D Printed Ceramics

- Why is vacuum degassing necessary for ZIF-8 impregnation? Achieve Uniform Macroporous Material Synthesis

- How does increasing the soaking zone temperature in a walking-beam furnace affect Titanium/Steel clad plates?

- What is the function of the electric arc furnace in the production of UMG-Si? Powering Silicon Transformation

- Why is a water quenching process employed when recovering reaction products? Achieve Instant Structural Preservation

- What is the mechanism of the steam and air mixture used in the decoking process? Essential High-Temp Reaction Guide