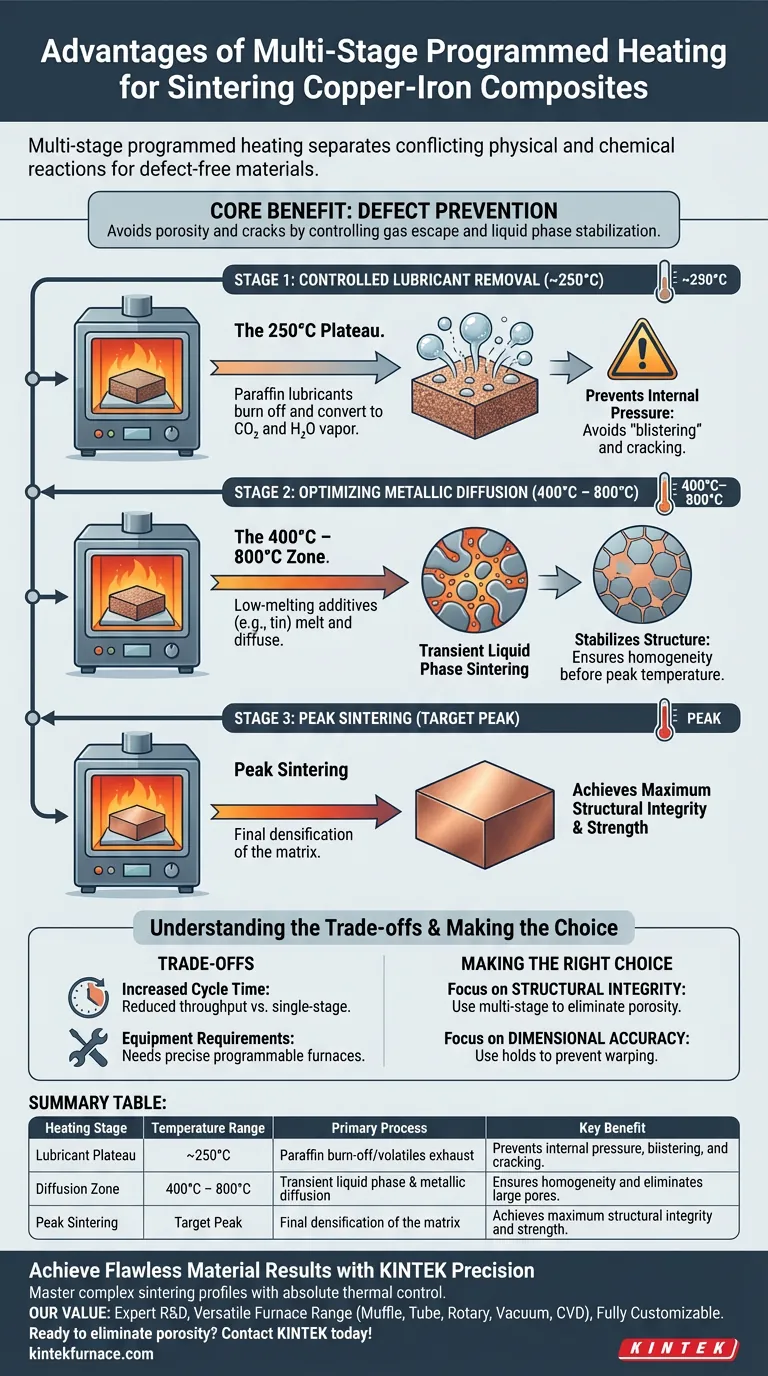

Multi-stage programmed heating offers the critical advantage of separating conflicting physical and chemical reactions during the sintering process. By introducing specific isothermal holding periods, you ensure that lubricants are fully exhausted and low-melting elements are properly diffused before the material reaches its final sintering temperature.

The core benefit of this approach is defect prevention. By allowing volatile gases to escape and liquid phases to stabilize at lower temperatures, you avoid the internal pressure and structural inconsistencies that cause porosity and cracks in the final copper-iron product.

The Mechanism of Defect Prevention

To understand the value of multi-stage heating, you must look at what happens inside the material at specific temperature zones.

Controlled Lubricant Removal

The 250°C Plateau During the forming process, paraffin lubricants are often mixed with the metal powder. A programmed hold at approximately 250°C is essential to manage these additives.

Exhausting Volatiles At this specific temperature, the paraffin burns off and converts into carbon dioxide and water vapor.

Preventing Internal Pressure If the temperature rises too quickly without this holding stage, these gases become trapped inside the densifying metal. This trapped gas creates internal pressure, leading to "blistering" or cracking in the final part.

Optimizing Metallic Diffusion

The 400°C – 800°C Zone Copper-iron composites often contain low-melting-point additives, such as tin. A secondary holding stage between 400°C and 800°C targets these specific components.

Facilitating Melt and Flow Holding in this range allows the low-melting metals to melt and diffuse through the matrix. This is often referred to as transient liquid phase sintering.

Stabilizing the Structure By allowing this diffusion to complete before the peak temperature is reached, you ensure the material structure is homogenous. This prevents the formation of large pores that occur if the liquid phase moves too rapidly or chaotically at higher temperatures.

Understanding the Trade-offs

While multi-stage heating produces superior material properties, it introduces operational complexities that must be managed.

Increased Cycle Time

Throughput Implications Adding isothermal holding stages inevitably extends the total sintering time. This reduces the number of batches you can process in a given shift compared to a direct, single-stage heating profile.

Equipment Requirements

Need for Precision You cannot achieve this with basic furnaces. It requires programmable heating equipment capable of maintaining precise heating rates and holding specific temperatures with minimal fluctuation.

Making the Right Choice for Your Goal

The decision to implement multi-stage heating depends on the strictness of your material requirements versus your production constraints.

- If your primary focus is Structural Integrity: Implement the multi-stage cycle to guarantee the removal of lubricants and the elimination of porosity.

- If your primary focus is Dimensional Accuracy: Use the programmed holds to prevent the rapid gas expansion that leads to warping or cracking.

Success in sintering copper-iron composites lies in patience; allowing the material to breathe at 250°C and stabilize at 400°C is the key to a flawless finish.

Summary Table:

| Heating Stage | Temperature Range | Primary Process | Key Benefit |

|---|---|---|---|

| Lubricant Plateau | ~250°C | Paraffin burn-off/exhausting volatiles | Prevents internal pressure, blistering, and cracking. |

| Diffusion Zone | 400°C – 800°C | Transient liquid phase & metallic diffusion | Ensures homogeneity and eliminates large pores. |

| Peak Sintering | Target Peak | Final densification of the matrix | Achieves maximum structural integrity and strength. |

Achieve Flawless Material Results with KINTEK Precision

Mastering complex sintering profiles like multi-stage heating requires absolute thermal control. KINTEK provides the advanced technology necessary to ensure every isothermal hold is executed with laboratory precision.

Our Value to Your Operations:

- Expert R&D & Manufacturing: Backed by years of expertise, KINTEK systems are built for consistency and durability.

- Versatile Furnace Range: We offer a comprehensive suite of Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for high-temperature lab applications.

- Fully Customizable: Our equipment is designed to be adapted to your unique material requirements and specific heating cycles.

Ready to eliminate porosity and improve the structural integrity of your copper-iron composites? Contact KINTEK today to discover how our customizable high-temp furnaces can transform your production quality!

Visual Guide

References

- Studying the Effect of Different Lubricant Materials on the Tribological Properties & Hardness of Cu-Fe Composite Prepared By PM. DOI: 10.47485/2832-9384.1048

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- Which performance characteristics of ultra-high temperature graphite furnaces are essential for Boron Carbide sintering?

- How does vacuum heat treatment improve industrial pure iron components? Enhance Magnetic and Mechanical Properties

- What materials can be processed using vacuum pressure sintering furnaces? Unlock High-Performance Material Densification

- How do costs compare between low vacuum and high vacuum furnaces? Find the Best Fit for Your Budget and Needs

- Why is vacuum brazing considered cost-effective? Reduce Costs with High-Quality Joints

- How does the multi-chamber continuous vacuum furnace improve industrial processes? Boost Efficiency and Quality

- What materials are suitable for gas quenching in a vacuum furnace? Ideal for High-Hardenability Alloys