In essence, vacuum heat treatment fundamentally improves industrial pure iron components by eliminating the negative influence of air during the heating and cooling process. This controlled environment prevents surface oxidation, ensures uniform temperature distribution, and allows for precise microstructural control, leading to enhanced mechanical toughness, superior magnetic properties, and a clean, bright surface finish.

By removing reactive elements like oxygen, vacuum heat treatment allows the material's intrinsic properties to be fully realized. It is less about adding something to the iron and more about protecting it from degradation at high temperatures to achieve a cleaner, more uniform, and higher-performing result.

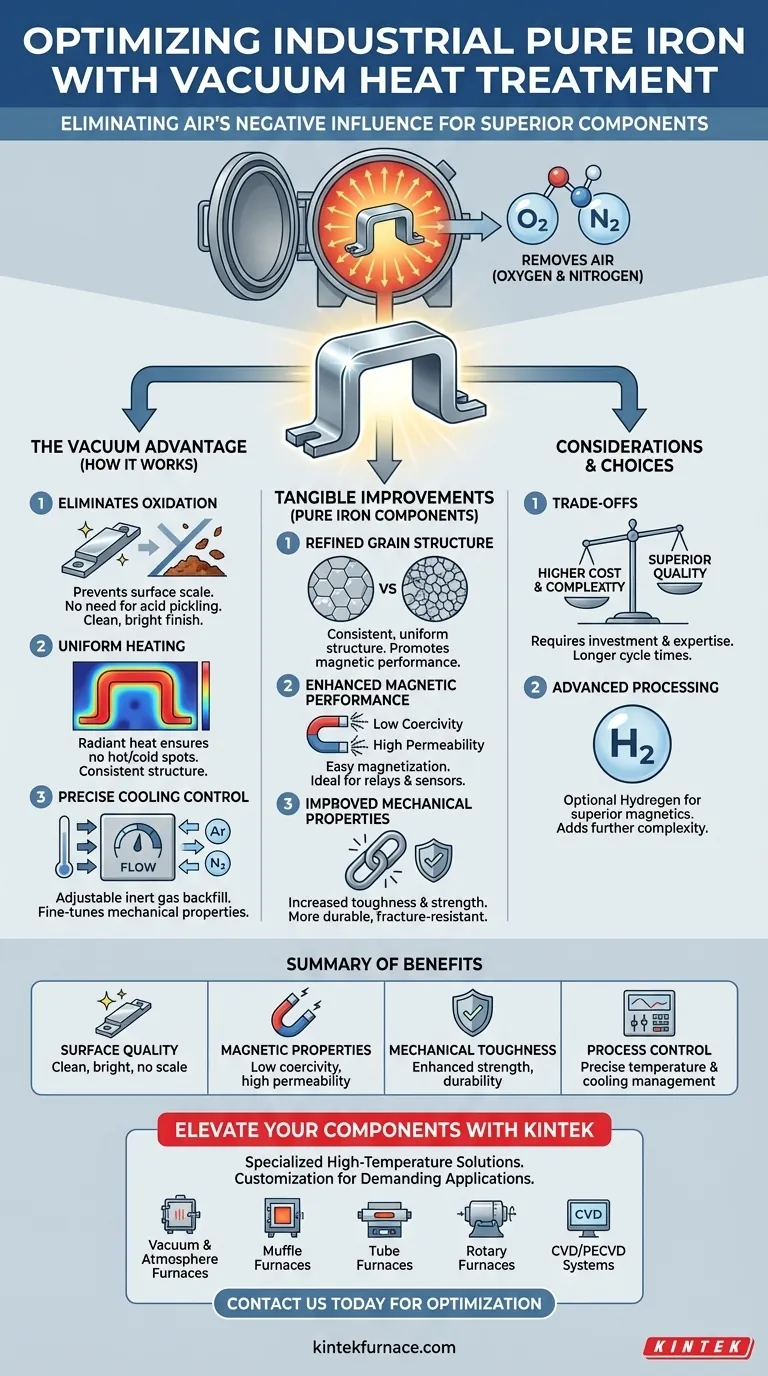

The Core Principle: Why a Vacuum Matters

To understand the benefits, we must first appreciate the problem that a vacuum solves. Traditional heat treatment occurs in the presence of air, which contains approximately 21% oxygen and 78% nitrogen. At high temperatures, these gases aggressively react with the metal's surface.

Eliminating Oxidation and Contamination

The most immediate effect of a vacuum is the removal of oxygen. This prevents the formation of surface oxides (scale), which are brittle and can compromise both the component's dimensions and its surface integrity.

The resulting part emerges from the furnace clean and bright, often eliminating the need for secondary cleaning processes like acid pickling or sandblasting. This is the reason for the dramatic increase in "brightness" noted for components like relay yokes.

Achieving Unparalleled Temperature Uniformity

In a vacuum, heat transfer occurs primarily through radiation. This method promotes exceptionally uniform heating across the entire part, regardless of its geometry.

There are no convection currents from atmospheric gases to cause hot or cold spots. This uniformity is critical for ensuring that the entire component undergoes the same structural transformation at the same time, preventing internal stresses and weak points.

Enabling Precise Control Over Cooling

The vacuum environment also provides meticulous control over the cooling (quenching) phase. The rate of cooling can be precisely managed by backfilling the sealed chamber with a specific volume of inert gas, such as nitrogen or argon.

This adjustable cooling rate is what allows metallurgists to fine-tune the final grain structure and, consequently, the material's mechanical properties like strength and toughness.

Tangible Improvements in Pure Iron Components

The controlled environment of a vacuum furnace directly translates to measurable improvements in the final product, especially for magnetically sensitive materials like industrial pure iron (e.g., DT4A).

Refined and Homogenous Grain Structure

Consistent heating and cooling cycles promote the growth of a uniform grain structure. For soft magnetic materials used in relays, a consistent and often larger grain size is desirable because it reduces impediments to magnetic domain wall movement, improving magnetic performance.

Enhanced Magnetic Performance

A clean, uniform microstructure with minimal internal stresses is the ideal state for a soft magnetic material. Vacuum treatment helps achieve low coercivity and high magnetic permeability, meaning the iron can be easily magnetized and demagnetized. This is a critical performance characteristic for relay cores and armatures.

Improved Mechanical Properties

By preventing surface embrittlement from oxidation and ensuring a homogenous internal structure, vacuum heat treatment directly enhances the material's toughness and strength. The final component is more durable and resistant to fracture.

Understanding the Trade-offs

While highly effective, vacuum heat treatment is not the default solution for every application. It involves specific considerations.

Cost and Cycle Time

Vacuum furnaces represent a significant capital investment and have higher operating costs compared to conventional atmospheric furnaces. The process of pumping down the chamber to a deep vacuum can also lead to longer overall cycle times.

Process Complexity

Operating a vacuum furnace requires a higher level of technical expertise to manage the vacuum levels, leak rates, and controlled gas backfilling. It is a more complex process than open-air heat treatment.

Advanced Processing with Hydrogen

For the most demanding soft magnetic applications, vacuum furnaces can be used with a partial pressure of hydrogen. This "vacuum-plus-hydrogen" treatment is even more effective at removing residual oxygen from the material, yielding superior magnetic properties, but it adds further complexity and safety protocols.

Making the Right Choice for Your Goal

The decision to use vacuum heat treatment should be driven by the performance requirements of the final component.

- If your primary focus is maximizing magnetic performance for relay cores or sensors: Vacuum heat treatment is the superior choice for achieving the required purity and structural uniformity.

- If your primary focus is achieving a clean, bright finish without costly post-processing: The prevention of oxidation makes vacuum treatment highly effective and can be more economical in the long run.

- If your primary focus is cost reduction for non-critical structural components: A conventional atmospheric heat treatment may be sufficient, provided minor surface oxidation and less precise structural control are acceptable.

By understanding these principles, you can specify a thermal process that delivers the precise material characteristics your high-performance components demand.

Summary Table:

| Improvement Area | Key Benefits |

|---|---|

| Surface Quality | Prevents oxidation, eliminates scale, and provides a clean, bright finish without secondary cleaning. |

| Magnetic Properties | Achieves low coercivity and high permeability for easy magnetization in relays and sensors. |

| Mechanical Toughness | Enhances strength and durability through uniform grain structure and reduced internal stresses. |

| Process Control | Allows precise temperature and cooling rate management for consistent microstructural outcomes. |

Ready to elevate your industrial pure iron components with advanced vacuum heat treatment?

At KINTEK, we specialize in high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a range of products including Vacuum & Atmosphere Furnaces, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise performance for demanding applications like relay cores and sensors, delivering enhanced magnetic properties, mechanical toughness, and clean surface finishes.

Contact us today to discuss how our solutions can optimize your heat treatment processes and boost your product quality!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing