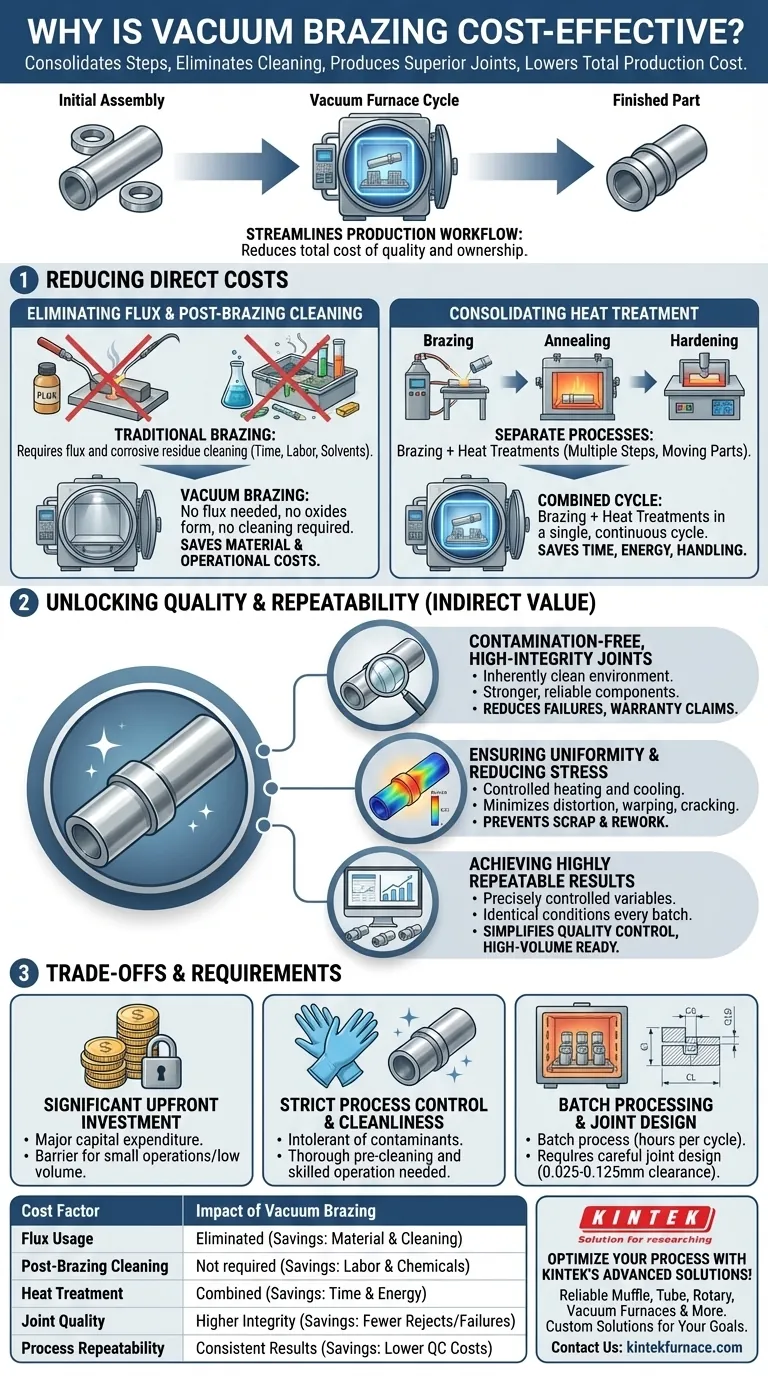

At its core, vacuum brazing is cost-effective because it consolidates multiple manufacturing steps, eliminates the need for expensive post-process cleaning, and produces exceptionally high-quality joints that reduce costly rejects and failures. This combination of process efficiency and superior output lowers the total cost of production, especially for complex or high-volume assemblies.

The true economic advantage of vacuum brazing isn't just about saving on materials or labor. It's about streamlining the entire production workflow, from initial assembly to the final, finished part, thereby reducing the total cost of quality and ownership.

How Vacuum Brazing Reduces Direct Costs

The most immediate cost savings come from how the vacuum environment fundamentally changes the joining process. It eliminates steps and materials that are standard requirements in other methods.

Eliminating Flux and Post-Brazing Cleaning

In traditional brazing, a chemical agent called flux is required to prevent the formation of oxides on the metal surfaces as they are heated. This flux leaves a corrosive residue that must be thoroughly cleaned off after brazing, a step that requires time, labor, and chemical solvents.

The high vacuum environment removes the oxygen, preventing oxides from forming in the first place. This completely eliminates the need for flux, saving on both the material cost of the flux itself and the significant operational costs associated with post-braze cleaning.

Consolidating Heat Treatment Processes

Many high-performance metal components require not only joining but also subsequent heat treatments like annealing, hardening, or aging to achieve their final mechanical properties.

A vacuum furnace allows these processes to be combined into a single, continuous cycle. Parts can be brazed and then immediately undergo a precisely controlled heat treatment and cooling sequence within the same chamber. This consolidation saves enormous amounts of time, energy, and material handling costs compared to moving parts between separate brazing and heat-treating stations.

The Indirect Value: Unlocking Quality and Repeatability

Beyond direct savings, the controlled nature of vacuum brazing produces higher quality parts more consistently, which provides significant, if less obvious, economic benefits.

Creating Contamination-Free, High-Integrity Joints

The vacuum environment is inherently clean, resulting in bright, shiny, and aesthetically perfect joints free from contamination. More importantly, this cleanliness ensures superior metallurgical bonds, leading to stronger and more reliable components. This higher quality reduces the rate of field failures, warranty claims, and rework.

Ensuring Uniformity and Reducing Stress

A vacuum furnace heats the entire assembly slowly and uniformly, then cools it in a highly controlled manner. This process minimizes residual stresses within the part, which can cause distortion, warping, or cracking. Maintaining the part's dimensional integrity and strength from the start prevents costly scrap or rework down the line.

Achieving Highly Repeatable Results

Every critical variable in the vacuum brazing cycle—temperature, time, and vacuum level—is precisely controlled by computer. This automation ensures that every part in a batch, and every batch thereafter, is processed under identical conditions. This high degree of repeatability is essential for high-volume production, minimizing variation and simplifying quality control.

Understanding the Trade-offs and Requirements

While highly effective, vacuum brazing is not the universal solution for every application. Its cost-effectiveness depends on understanding its specific demands.

Significant Upfront Investment

High-quality vacuum furnaces represent a major capital expenditure. The cost of the equipment can be a significant barrier for smaller operations or low-volume production runs.

Strict Process Control and Cleanliness

The process is intolerant of contaminants. Successful vacuum brazing demands extremely thorough pre-cleaning of parts, clean assembly environments, and skilled operators to manage the equipment. Any failure in these preparatory steps can compromise the entire batch.

Batch Processing and Joint Design

Vacuum brazing is a batch process. The entire cycle of heating, soaking, and cooling can take several hours, which may be less efficient than continuous methods for certain workflows. Furthermore, it requires careful joint design, with typical clearances between 0.025 mm and 0.125 mm, to ensure proper capillary action of the brazing alloy.

Making the Right Choice for Your Goal

To determine if vacuum brazing is the right choice, align its strengths with your primary manufacturing objective.

- If your primary focus is high-volume production of complex parts: Vacuum brazing is exceptionally cost-effective due to its ability to perform multiple joints and heat treatments in a single, repeatable cycle.

- If your primary focus is mission-critical component quality: The process delivers superior, contamination-free joints with minimal residual stress, reducing the long-term cost of failure and ensuring reliability.

- If your primary focus is low-volume work or rapid prototyping: The high capital investment and setup requirements may make other methods, such as torch or induction brazing, a more practical and economical choice.

Ultimately, the cost-effectiveness of vacuum brazing is realized by evaluating the total manufacturing lifecycle, not just the cost of a single operation.

Summary Table:

| Cost Factor | Impact of Vacuum Brazing |

|---|---|

| Flux Usage | Eliminated, saving material and cleaning costs |

| Post-Brazing Cleaning | Not required, reducing labor and chemical expenses |

| Heat Treatment | Combined with brazing in one cycle, saving time and energy |

| Joint Quality | Higher integrity, fewer rejects and failures |

| Process Repeatability | Consistent results, lowering quality control costs |

Optimize your manufacturing process with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, helping you achieve cost savings and superior results. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control