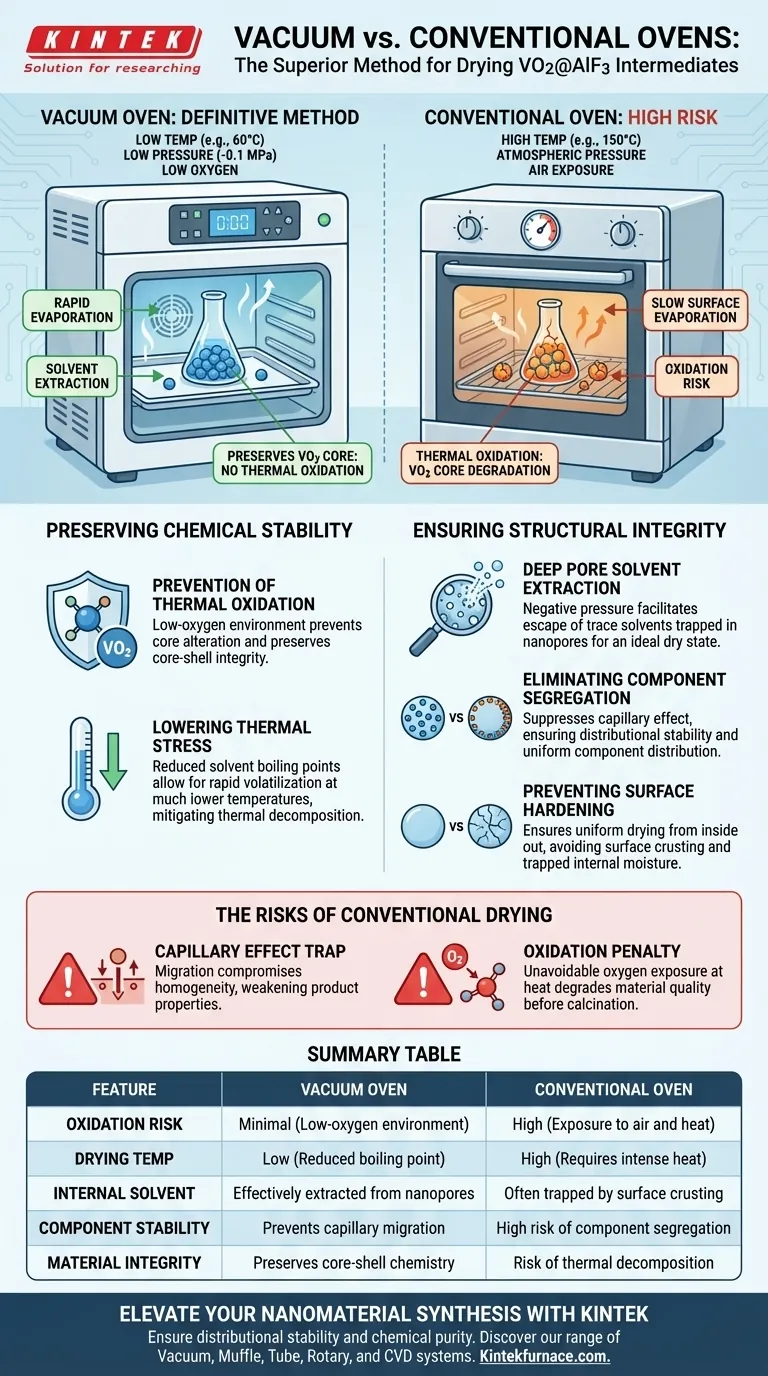

Vacuum drying is the definitive method for processing VO2@AlF3 intermediate products. By lowering the ambient pressure, a vacuum oven allows solvents to evaporate rapidly at significantly lower temperatures than a conventional oven. This specific environment is critical for preventing the thermal oxidation of the VO2 cores while ensuring the thorough removal of moisture from deep within the material’s nanopores.

The core advantage of vacuum drying is its ability to decouple temperature from evaporation. It allows you to achieve a "bone-dry" state without subjecting the sensitive VO2 core to the oxidation and structural segregation risks inherent in high-temperature atmospheric drying.

Preserving Chemical Stability

Prevention of Thermal Oxidation

The primary danger in drying VO2@AlF3 is the sensitivity of the VO2 cores. In a conventional oven, high temperatures combined with air exposure lead to rapid thermal oxidation.

A vacuum oven removes the air, creating a low-oxygen environment. This allows the material to dry without altering the chemical valency of the vanadium, preserving the integrity of the core-shell structure.

Lowering the Thermal Stress

Vacuum conditions significantly reduce the boiling point of solvents. This allows for rapid volatilization at much lower temperatures compared to atmospheric conditions.

This is essential for heat-sensitive chemical substances. It mitigates the risk of thermal decomposition that often occurs when forcing evaporation through high heat alone.

Ensuring Structural Integrity

Deep Pore Solvent Extraction

VO2@AlF3 materials rely on a complex nanopore structure. Conventional drying often struggles to extract solvents trapped deep within these pores.

The negative pressure of the vacuum facilitates the escape of these trace solvents. This ensures the core-shell material is in an ideal dry state prior to critical high-temperature calcination steps.

Eliminating Component Segregation

When drying at atmospheric pressure, rapid surface evaporation can draw internal liquid outward. This creates a "capillary effect" where active metal salt components migrate to the surface.

Vacuum drying suppresses this migration. By enabling evaporation from within the bulk material rather than just the surface, it ensures the distributional stability of components throughout the precursor.

Preventing Surface Hardening

Conventional ovens can cause the outer layer of a sample to dry and harden too quickly. This creates a crust that traps internal moisture inside the material.

Vacuum drying prevents this surface hardening. It ensures uniform drying from the inside out, avoiding the mechanical instability and cracking associated with trapped internal solvents.

The Risks of Conventional Drying

While conventional ovens are ubiquitous, they present specific chemical and physical risks for VO2@AlF3 production that vacuum ovens resolve.

The Capillary Effect Trap

In standard ovens, the migration of components toward the outer surface compromises the homogeneity of the final product. This results in an uneven distribution of active materials, weakening the electrochemical or physical properties of the final product.

The Oxidation Penalty

The most significant trade-off of using a conventional oven is the unavoidable exposure to oxygen at heat. For VO2, this exposure invariably degrades the material quality before the final calcination stage even begins.

Making the Right Choice for Your Goal

To optimize the quality of your VO2@AlF3 intermediates, align your drying method with your specific stability requirements.

- If your primary focus is Chemical Purity: Use vacuum drying to lower process temperatures and eliminate oxygen, preventing the thermal oxidation of the VO2 cores.

- If your primary focus is Structural Homogeneity: Rely on the vacuum environment to prevent the capillary effect, ensuring active components remain evenly distributed rather than migrating to the surface.

- If your primary focus is Deep Drying: Utilize negative pressure to extract trace solvents from nanopores that atmospheric heat cannot effectively reach without damaging the material.

Vacuum drying is not just a faster alternative; it is a chemical necessity for maintaining the integrity of sensitive core-shell nanostructures.

Summary Table:

| Feature | Vacuum Oven | Conventional Oven |

|---|---|---|

| Oxidation Risk | Minimal (Low-oxygen environment) | High (Exposure to air and heat) |

| Drying Temp | Low (Reduced boiling point) | High (Requires intense heat) |

| Internal Solvent | Effectively extracted from nanopores | Often trapped by surface crusting |

| Component Stability | Prevents capillary migration | High risk of component segregation |

| Material Integrity | Preserves core-shell chemistry | Risk of thermal decomposition |

Elevate Your Nanomaterial Synthesis with KINTEK

Don't compromise the integrity of your sensitive VO2@AlF3 intermediates with inadequate drying methods. Backed by expert R&D and precision manufacturing, KINTEK offers a wide range of laboratory solutions including high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems. Our furnaces are fully customizable to meet the unique thermal profiles and vacuum requirements of your advanced material research.

Ensure distributional stability and chemical purity in your lab today. Contact our technical specialists at KINTEK to find the perfect drying solution for your unique needs.

Visual Guide

References

- Lingfeng Jiang, Li Zhao. Chemical Deposition Method for Preparing VO2@AlF3 Core–Shell-Structured Nanospheres for Smart Temperature-Control Coating. DOI: 10.3390/coatings15091045

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is 600 °C critical for ZIF-8 carbonization? Achieve Optimal Surface Area and Functional Group Retention

- How does the use of a stainless steel high-pressure autoclave affect ZnS/CeO2@CNT formation? Optimize Catalyst Growth

- How does the use of carbon dioxide and a flow meter impact the physical activation of biochar? Master Pore Development

- Why is a high-precision furnace required for carbon aerogel activation? Achieve Optimal Pore Development & Control

- What are the technical advantages of using an industrial-grade microwave-assisted hydrothermal synthesis system? Master CeO2 Morphology

- What is the function of a forced air drying oven for biochar? Optimize Moringa Oleifera Shell Pre-treatment

- How does a constant temperature heating device influence battery performance? Enhance Lithium Dendrite Research Accuracy

- What is the purpose of preheating reinforcement particles? Optimize AMC Stir Casting Results