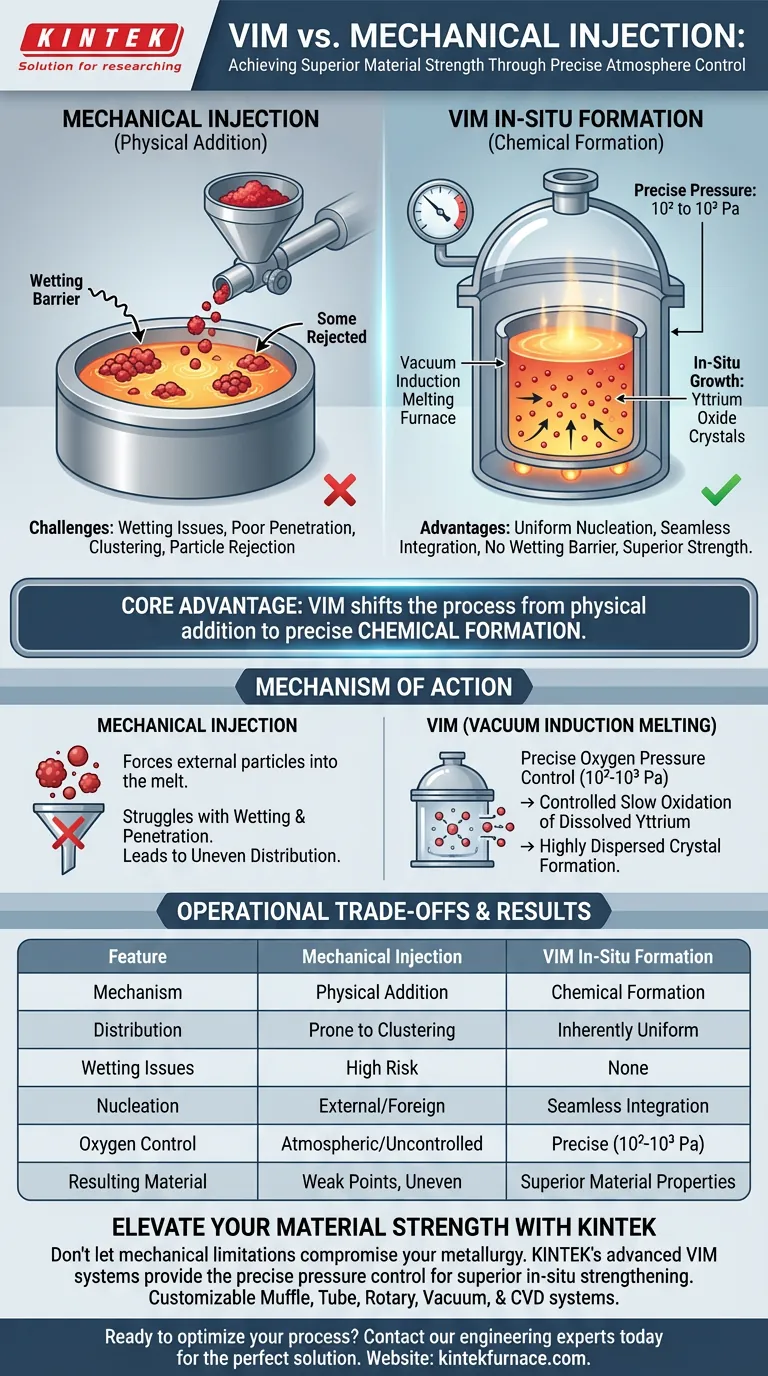

Vacuum Induction Melting (VIM) fundamentally outperforms mechanical injection by shifting the process from physical addition to chemical formation. By utilizing a vacuum pump system to precisely regulate residual oxygen pressure between 10² and 10³ Pa, VIM allows for the slow, in-situ growth of oxide particles, ensuring a level of integration that external injection methods simply cannot match.

Core Takeaway VIM technology circumvents the physical barriers of "wetting" and penetration that plague mechanical injection methods. By controlling the oxidation environment, VIM enables the uniform nucleation of strengthening particles directly within the steel matrix, rather than attempting to force them into the liquid metal from the outside.

The Mechanism of In-Situ Formation

Precision Pressure Regulation

The defining feature of this VIM application is the ability to maintain a specific residual oxygen pressure, typically between 10² and 10³ Pa.

This is not merely about creating a void; it is about creating a stable, low-oxygen environment. This precise control is the catalyst for the entire strengthening process.

Controlled Slow Oxidation

Under these specific pressure conditions, dissolved elements—specifically yttrium—undergo a slow oxidation process.

Because the yttrium is already dissolved in the liquid metal, this reaction happens at a molecular level throughout the entire melt. This facilitates the in-situ formation of highly dispersed yttrium oxide crystals.

Overcoming Mechanical Limitations

The Wetting Barrier

Mechanical injection relies on forcing external particles into a liquid melt.

A major failure point in this method is wetting—the ability of the liquid metal to bond with the solid particle. If wetting is poor, the particles often cluster at the surface or are rejected by the melt entirely.

Penetration and Distribution

Even if particles enter the melt, mechanical injection struggles with penetration.

Achieving a homogenous mix requires overcoming the natural resistance of the fluid. This often leads to uneven clustering, creating weak points in the final material rather than strengthening it.

The Result: Superior Material Properties

Uniform Distribution

Because the VIM process grows crystals from dissolved elements, the distribution is inherently uniform.

Wherever the yttrium was dissolved, the oxide crystals form. This eliminates the "clumping" issues associated with mechanical mixing.

Enhanced Nucleation

The controlled environment promotes effective nucleation of the strengthening particles.

These in-situ formed crystals integrate seamlessly into the steel matrix, providing superior reinforcement compared to foreign particles introduced mechanically.

Understanding the Operational Trade-offs

Process Sensitivity

The advantages of VIM rely entirely on maintaining the strict pressure window of 10² to 10³ Pa.

Deviating from this range can disrupt the slow oxidation rate. If the pressure is too high, oxidation may occur too rapidly; too low, and the crystals may not form effectively.

Equipment Complexity

Unlike simple mechanical injection setups, this process requires a robust vacuum pump system.

Operators must manage not just the temperature and composition of the melt, but also the atmospheric physics of the chamber, adding a layer of complexity to the production process.

Making the Right Choice for Your Goal

To determine if VIM is the correct approach for your metallurgy project, evaluate your specific requirements:

- If your primary focus is maximum material strength: Prioritize VIM to ensure uniform distribution and effective nucleation of yttrium oxide crystals.

- If your primary focus is avoiding particle rejection: Use VIM to bypass the wetting and penetration issues inherent in mechanical injection.

By controlling the atmosphere, you stop fighting the physics of the melt and start using chemistry to build a superior steel matrix.

Summary Table:

| Feature | Mechanical Injection | VIM In-Situ Formation |

|---|---|---|

| Mechanism | Physical addition of particles | Chemical formation in-situ |

| Distribution | Prone to clustering/clumping | Inherently uniform distribution |

| Wetting Issues | High risk of particle rejection | No wetting barriers |

| Nucleation | External/Foreign particles | Seamless matrix integration |

| Oxygen Control | Atmospheric/Uncontrolled | Precise (10² to 10³ Pa) |

Elevate Your Material Strength with KINTEK

Don't let mechanical limitations compromise your metallurgy. KINTEK’s advanced Vacuum Induction Melting (VIM) systems provide the precise pressure control and atmospheric stability required for superior in-situ strengthening.

Backed by expert R&D and world-class manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique laboratory or industrial needs. Our high-temperature furnaces ensure you achieve the uniform nucleation and chemical precision your project demands.

Ready to optimize your heat treatment process? Contact our engineering experts today to find the perfect furnace solution for your application.

Visual Guide

References

- Alexandr Panichkin, Alexandr Arbuz. RESEARCH OF INJECTION METHODS FOR Y2O3 NANOPARTICLES INTO NICKEL- FREE STAINLESS STEEL DURING INDUCTION VACUUM REMELTING. DOI: 10.59957/jctm.v59.i1.2024.20

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the major challenges faced by the IGBT induction melting furnace market? Navigating High Costs and Complexity

- Why is repeated flipping and remelting necessary when producing Sm-Co-Fe alloy ingots in an arc furnace? Key Insights

- Why is it necessary to reduce the applied secondary voltage during the arc furnace process? Protect Your Furnace and Boost Efficiency

- What is the working principle of an induction melting furnace? Achieve Fast, Clean, and Controllable Metal Melting

- What are the technical advantages of using an induction furnace for lithium battery recycling over resistance heating?

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What advantages do induction furnaces offer for aluminum melting? Boost Speed, Purity, and Efficiency

- What role does an electric melting furnace play in the production of Al7075/Fe3O4/RHS composites? Precision Liquefaction